Turbojets are jet engines that produce thrust by expelling high-speed exhaust gases, primarily used in military aircraft and early commercial jets due to their high-speed efficiency. These engines operate by compressing air, mixing it with fuel, igniting the mixture, and then accelerating the exhaust out of the nozzle to generate propulsion. Discover how turbojets revolutionize aviation and explore their advantages and limitations in the full article.

Table of Comparison

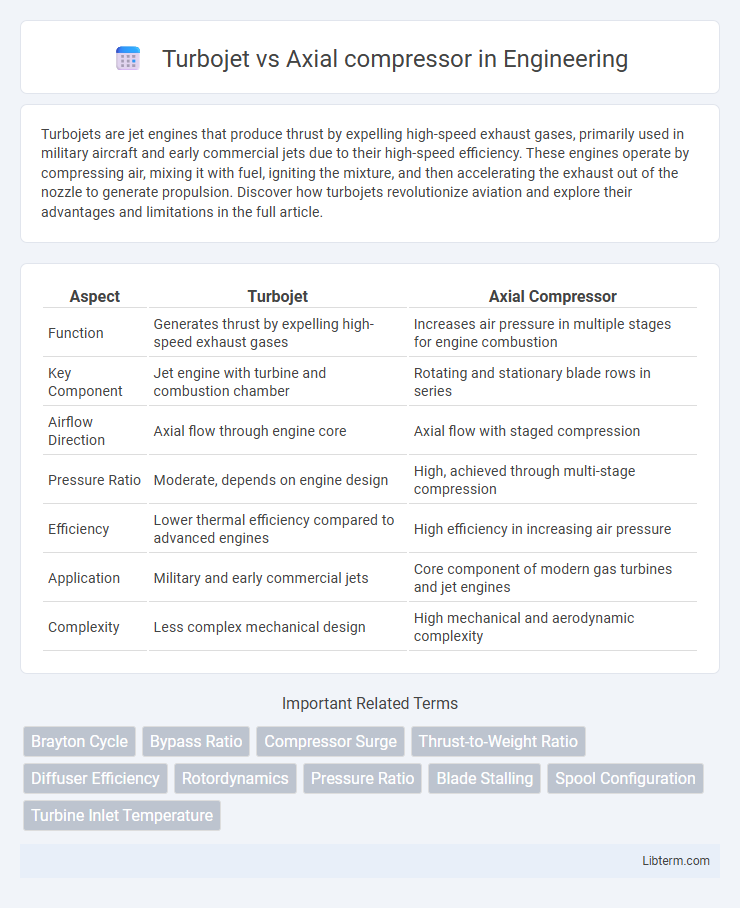

| Aspect | Turbojet | Axial Compressor |

|---|---|---|

| Function | Generates thrust by expelling high-speed exhaust gases | Increases air pressure in multiple stages for engine combustion |

| Key Component | Jet engine with turbine and combustion chamber | Rotating and stationary blade rows in series |

| Airflow Direction | Axial flow through engine core | Axial flow with staged compression |

| Pressure Ratio | Moderate, depends on engine design | High, achieved through multi-stage compression |

| Efficiency | Lower thermal efficiency compared to advanced engines | High efficiency in increasing air pressure |

| Application | Military and early commercial jets | Core component of modern gas turbines and jet engines |

| Complexity | Less complex mechanical design | High mechanical and aerodynamic complexity |

Introduction to Turbojet and Axial Compressor Technologies

Turbojet engines utilize axial compressors to increase air pressure by passing it through multiple stages of rotating and stationary blades, enhancing combustion efficiency and thrust generation. Axial compressors, a key component in turbojet technology, are designed to compress large volumes of air with minimal pressure loss, making them ideal for high-speed jet propulsion. The integration of axial compressors in turbojets allows for compact engine design, higher compression ratios, and improved overall engine performance in aerospace applications.

Fundamentals of Turbojet Engines

Turbojet engines rely on axial compressors to increase air pressure before combustion, enhancing thrust efficiency by compressing airflow through multiple rotating stages. The axial compressor's design enables continuous airflow and higher pressure ratios compared to centrifugal compressors, making it essential for high-speed aircraft propulsion. Understanding the interaction between the turbojet's combustion chamber and the axial compressor is fundamental for optimizing engine performance and fuel efficiency.

Principles of Axial Compressor Operation

Axial compressors operate on the principle of continuously accelerating air through multiple stages of rotor and stator blades, increasing the pressure gradually while maintaining axial flow direction. The rotor blades impart kinetic energy to the air, which is converted to pressure energy in the stator blades, enabling high-pressure ratios suitable for turbojet engines. This design allows axial compressors to achieve efficient air compression with minimal flow distortion, essential for maintaining optimal engine performance at various operating speeds.

Design Differences: Turbojet vs Axial Compressor

Turbojets utilize axial compressors to increase air pressure through multiple rotating and stationary blade stages, enhancing compression efficiency and enabling high-speed propulsion. Unlike standalone axial compressors, which are solely designed to compress airflow in various industrial applications, turbojet compressors must be optimized to operate under extreme temperature and aerodynamic conditions within an engine nacelle. The integration into a turbojet involves considerations like blade aerodynamics, material durability, and rotational speed to maximize thrust output and fuel efficiency.

Efficiency Comparison: Turbojet Versus Axial Compressor

Turbojet engines rely heavily on axial compressors to achieve high-efficiency air compression essential for optimal thrust generation. Axial compressors, characterized by multiple rotating and stationary blade stages, maintain superior pressure ratios and airflow uniformity, contributing to enhanced overall engine efficiency in turbojets. Comparing performance metrics, axial compressors typically exhibit higher isentropic efficiency and better adaptability to varying operational speeds than alternative compressor types used in turbojets.

Performance Metrics and Applications

Turbojet engines excel in high-speed, high-altitude performance with thrust output optimized for supersonic flight, benefiting from axial compressor stages that provide efficient air compression and pressure ratios above 30:1. Axial compressors, essential in turbojets, enhance engine efficiency by maintaining high mass flow rates and smooth airflow, critical for applications such as military fighter jets and commercial supersonic aircraft. Performance metrics like specific fuel consumption (SFC) and thrust-to-weight ratio highlight the turbojet's advantage in speed and altitude, while axial compressors contribute to improved engine durability and operational stability in demanding environments.

Technological Advancements in Turbojets and Compressors

Technological advancements in turbojets have focused on improving fuel efficiency and thrust-to-weight ratios through enhanced materials like single-crystal turbine blades and advanced cooling techniques. Axial compressors have seen significant innovation with the development of variable geometry stators and 3D aerodynamic blade designs, increasing pressure ratios and compressor stability. Integration of digital engine control systems further optimizes performance by precisely managing compressor blade angles and fuel flow in real-time.

Maintenance and Durability Comparison

Turbojet engines typically require more frequent maintenance due to higher operating temperatures and rotational speeds, which increase component wear and fatigue. Axial compressors, being integral to both turbojets and turbofans, benefit from advanced materials and design improvements that enhance durability and reduce maintenance intervals. Overall, axial compressors exhibit improved longevity and easier serviceability compared to older turbojet configurations, leading to lower lifecycle costs.

Environmental Impact and Fuel Consumption

Turbojets typically exhibit higher fuel consumption and greater emissions due to their reliance on simple axial compressors that prioritize thrust over efficiency, resulting in increased environmental impact. Axial compressors in turbojet engines generate significant noise pollution and release higher levels of nitrogen oxides (NOx) compared to more advanced compressor types. Optimizing fuel efficiency and reducing environmental harm requires integrating axial compressors with turbofan designs or adopting newer technologies such as geared turbofans or contra-rotating fans.

Future Trends in Turbojet and Axial Compressor Development

Future trends in turbojet and axial compressor development emphasize improving efficiency and reducing emissions through advanced materials, additive manufacturing, and AI-driven design optimization. Integration of variable geometry compressors and hybrid electric-turbojet systems is accelerating to enhance performance across diverse operating conditions. Research into supersonic combustion and ultra-high pressure ratios promises breakthroughs in propulsion efficiency for next-generation aerospace engines.

Turbojet Infographic

libterm.com

libterm.com