Watt's linkage is a mechanical assembly designed to allow straight-line movement while converting rotary motion into linear motion with minimal deviation. This linkage is commonly used in automotive suspensions and steam engines to ensure precise control and stability. Explore the rest of the article to understand how Watt's linkage can enhance Your mechanical designs.

Table of Comparison

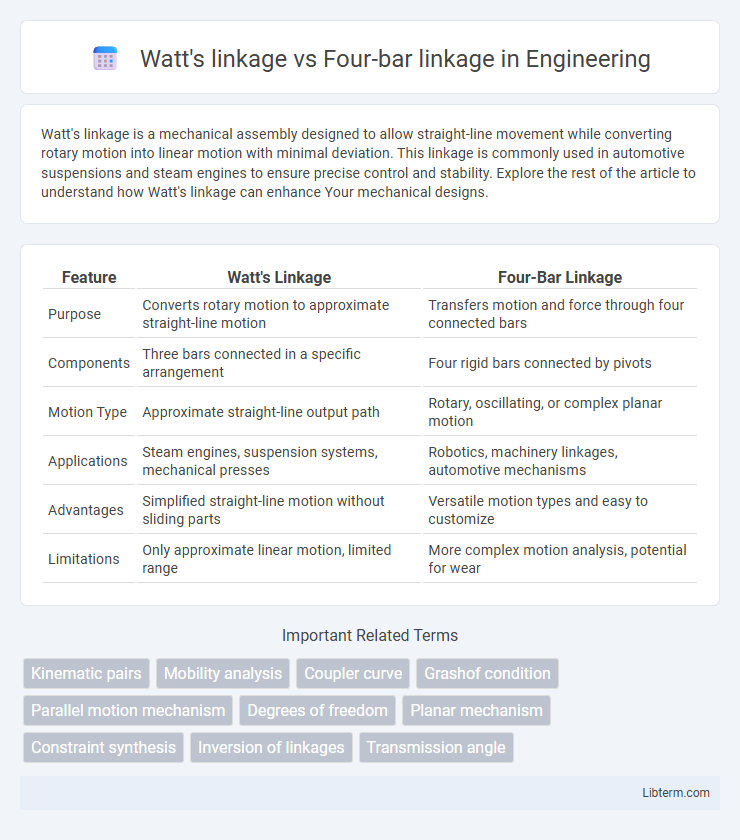

| Feature | Watt's Linkage | Four-Bar Linkage |

|---|---|---|

| Purpose | Converts rotary motion to approximate straight-line motion | Transfers motion and force through four connected bars |

| Components | Three bars connected in a specific arrangement | Four rigid bars connected by pivots |

| Motion Type | Approximate straight-line output path | Rotary, oscillating, or complex planar motion |

| Applications | Steam engines, suspension systems, mechanical presses | Robotics, machinery linkages, automotive mechanisms |

| Advantages | Simplified straight-line motion without sliding parts | Versatile motion types and easy to customize |

| Limitations | Only approximate linear motion, limited range | More complex motion analysis, potential for wear |

Introduction to Mechanical Linkages

Watt's linkage and four-bar linkage are fundamental mechanical linkages used to convert rotary motion into constrained planar motion. Watt's linkage, designed by James Watt, provides approximate straight-line motion through a combination of three bars connected in a pantograph-inspired configuration, often utilized in steam engine mechanisms. Four-bar linkage, consisting of four rigid bars connected by pivots, offers a versatile range of motions including oscillation and rotation, commonly applied in robotic arms and suspension systems.

Overview of Watt’s Linkage

Watt's linkage is a mechanical linkage invented by James Watt to convert rotary motion into approximate straight-line motion, primarily used in steam engine pistons. It consists of three connected bars forming a double-rocker mechanism that guides a point along a nearly straight path, minimizing vertical deviation compared to a simple four-bar linkage. Unlike the four-bar linkage, which has a single loop of four rotating bars, Watt's linkage provides improved straight-line guidance with fewer geometric constraints.

Fundamentals of Four-Bar Linkage

The four-bar linkage consists of four rigid bars connected by pivot joints, forming a closed loop that creates complex planar motion through simple rotational input. Its fundamental mechanics rely on the Grashof condition for determining mobility and predictability of motion paths, making it versatile for various mechanical applications. Compared to Watt's linkage, the four-bar linkage offers more design flexibility and range in producing diverse output motions such as oscillation, rotation, and translation.

Historical Development and Applications

Watt's linkage, designed by James Watt in the 18th century to convert rotary motion into approximate straight-line motion, played a critical role in steam engine mechanisms and early mechanical engineering. The Four-bar linkage, with roots tracing back to the 19th century, evolved as a versatile mechanical system, widely used in automotive suspensions, robotic arms, and industrial machinery for precise motion control. Both linkages significantly contributed to the advancement of kinematic chains, influencing modern mechanical design and motion analysis.

Kinematic Motion Paths: Watt’s vs Four-Bar

Watt's linkage produces a near straight-line motion path by combining three bars arranged in a specific tri-bar configuration that approximates linear displacement, ideal for applications requiring constrained planar motion. The four-bar linkage, consisting of four rigid bars connected by pivot joints, generates a wider variety of complex motion paths, including rotational, oscillatory, and oscillating linear motions, making it versatile for mechanisms needing diverse kinematic outputs. While Watt's linkage excels in replicating approximate straight-line paths with limited angular deviation, four-bar linkages offer greater adaptability in controlling motion trajectories in mechanical systems.

Precision and Accuracy in Linkage Mechanisms

Watt's linkage offers enhanced precision in converting linear motion to approximate straight-line motion due to its unique three-bar arrangement that limits lateral deviation. In contrast, a four-bar linkage provides greater flexibility but may sacrifice accuracy, as its motion path depends heavily on the relative lengths and pivot positions of its links. For applications requiring consistent and precise linear guidance, Watt's linkage generally outperforms four-bar linkages by minimizing error in path deviation.

Structural Simplicity and Complexity Comparison

Watt's linkage features a simpler structure with three links and two fixed pivots, designed primarily to generate approximate straight-line motion, making it easier to manufacture and maintain. The four-bar linkage consists of four rigid links connected in a loop with four rotating pairs, offering greater motion versatility but increasing structural complexity and potential for wear. The simpler kinematic arrangement of Watt's linkage results in fewer moving parts and reduced joint friction compared to the more intricate four-bar system.

Industrial and Automotive Use Cases

Watt's linkage provides precise vertical motion control, making it ideal for automotive suspension systems that require minimal lateral movement and improved ride stability in industrial machinery. Four-bar linkages offer versatile motion paths and are widely used for robotic arms, manufacturing automation, and engine valve mechanisms due to their adaptability and compact design. Industrial applications often favor Watt's linkage for load-bearing tasks with constrained movement, while automotive systems rely on four-bar linkages for complex articulations and efficient transmission of motion.

Design Considerations and Limitations

Watt's linkage offers precise straight-line motion and reduced complexity in guiding paths compared to the traditional Four-bar linkage, making it ideal for applications demanding linear approximations with limited components. Four-bar linkages provide greater flexibility in synthesizing complex motion profiles but often require more intricate design calculations and can introduce larger deviations from ideal paths due to their rotational joint arrangements. Designers must weigh the trade-offs between the constrained linearity of Watt's linkage and the versatile but potentially less accurate movements of Four-bar linkages when selecting a mechanism for specific kinematic requirements.

Future Trends in Linkage Mechanism Innovations

Advancements in linkage mechanism innovations emphasize enhancing precision and adaptability in Watt's linkage and four-bar linkage systems through integration with smart materials and real-time sensor feedback. The development of adaptive control algorithms and lightweight composite materials anticipates improved energy efficiency and durability for applications in robotics and automotive suspension systems. Emerging trends also explore miniaturization and embedded actuation, enabling more compact and multifunctional linkage designs suitable for next-generation microelectromechanical systems (MEMS) and wearable technologies.

Watt's linkage Infographic

libterm.com

libterm.com