Brazing is a metal-joining process that uses a filler metal melted above 450degC to bond two or more parts without melting the base materials. This technique provides strong, durable joints with excellent corrosion resistance and is widely used in automotive, HVAC, and aerospace industries. Explore the rest of the article to learn how brazing can enhance your manufacturing projects.

Table of Comparison

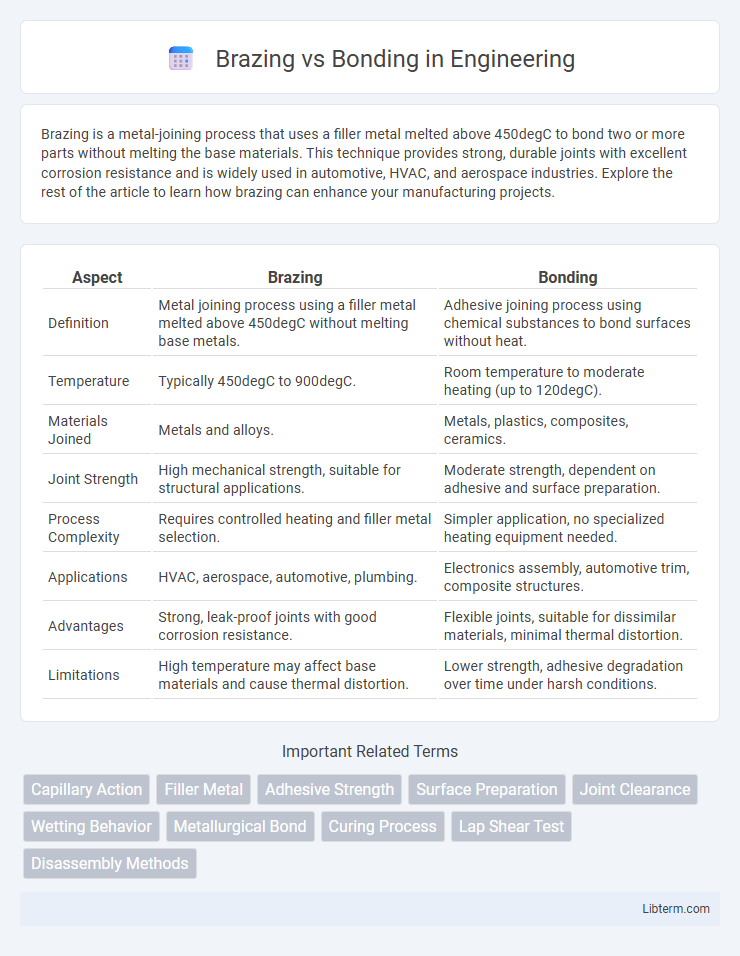

| Aspect | Brazing | Bonding |

|---|---|---|

| Definition | Metal joining process using a filler metal melted above 450degC without melting base metals. | Adhesive joining process using chemical substances to bond surfaces without heat. |

| Temperature | Typically 450degC to 900degC. | Room temperature to moderate heating (up to 120degC). |

| Materials Joined | Metals and alloys. | Metals, plastics, composites, ceramics. |

| Joint Strength | High mechanical strength, suitable for structural applications. | Moderate strength, dependent on adhesive and surface preparation. |

| Process Complexity | Requires controlled heating and filler metal selection. | Simpler application, no specialized heating equipment needed. |

| Applications | HVAC, aerospace, automotive, plumbing. | Electronics assembly, automotive trim, composite structures. |

| Advantages | Strong, leak-proof joints with good corrosion resistance. | Flexible joints, suitable for dissimilar materials, minimal thermal distortion. |

| Limitations | High temperature may affect base materials and cause thermal distortion. | Lower strength, adhesive degradation over time under harsh conditions. |

Introduction to Brazing and Bonding

Brazing creates strong, metal-to-metal joints by melting a filler metal above 450degC without melting the base metals, commonly used in plumbing and automotive industries for durable connections. Bonding relies on adhesives or chemical agents to join surfaces, offering flexibility for dissimilar materials and applications in aerospace and electronics where stress absorption is critical. Both methods enhance structural integrity but differ in temperature requirements, materials compatibility, and joint characteristics.

Defining Brazing: Process and Principles

Brazing is a metal-joining process that involves heating a filler metal above its melting point and flowing it into the joint between two base metals without melting them. This capillary action creates a strong, permanent bond by diffusion and adhesion at the interface, typically performed at temperatures above 450degC. The process offers excellent joint strength, corrosion resistance, and the ability to join dissimilar metals, making it ideal for applications in aerospace, automotive, and HVAC industries.

Bonding Explained: Types and Techniques

Bonding involves joining materials using adhesives, which chemically or physically adhere surfaces without melting the base metals. Common types include epoxy bonding, anaerobic bonding, and UV curing, each selected based on material compatibility and environmental resistance. Advanced techniques such as structural bonding provide high-strength joints in automotive and aerospace industries, offering durable and lightweight alternatives to mechanical fastening.

Material Compatibility: Brazing vs Bonding

Brazing offers exceptional compatibility with a wide range of metals including steel, copper, aluminum, and brass by creating strong metallurgical joints through melting a filler metal. Bonding excels in joining dissimilar materials such as plastics, composites, and metals without altering the base materials, relying on adhesive formulas tailored for specific substrates. Material compatibility favors brazing for metal-to-metal connections demanding durability and thermal resistance, while bonding provides versatility for lightweight, non-metal, or mixed-material assemblies requiring flexibility and corrosion resistance.

Strength and Durability Comparison

Brazing creates strong metallurgical joints by melting a filler metal that bonds base metals without melting them, resulting in high strength and excellent durability under thermal and mechanical stress. Bonding, often involving adhesives, provides moderate strength suitable for applications with lower load demands but excels in flexibility and resistance to vibration. Brazed joints typically outperform bonded joints in structural applications requiring long-term durability and high tensile strength.

Temperature Resistance and Performance

Brazing provides superior temperature resistance, withstanding temperatures typically between 450degC and 900degC, making it ideal for high-heat applications in aerospace and automotive industries. Bonding, particularly adhesive bonding, offers lower temperature resistance, generally up to about 150degC to 250degC, but excels in vibration damping and flexibility. Performance-wise, brazed joints create strong metallurgical bonds that endure mechanical stress and thermal cycling, while bonded joints provide excellent sealing and stress distribution without metal distortion.

Cost Analysis: Brazing vs Bonding

Brazing typically incurs higher initial costs due to the need for specialized equipment, skilled labor, and precise temperature control, while bonding often requires less expensive adhesives and simpler application methods. Maintenance and operational expenses for brazing may increase because of energy consumption and potential material distortion, whereas bonding generally offers cost savings through faster processing and lower energy use. Long-term cost efficiency depends on factors like joint strength, durability, production volume, and material compatibility, making bonding more economical for lightweight applications and brazing preferable for high-strength metal joints.

Application Suitability and Industry Use

Brazing excels in joining metals with high strength and temperature resistance, making it ideal for aerospace, automotive, and HVAC industries due to its durability and ability to withstand extreme conditions. Bonding, using adhesives, offers flexibility and is suitable for dissimilar materials like composites and plastics, commonly applied in electronics, consumer goods, and automotive sectors where vibration damping and lightweight assemblies are critical. Industry selection depends on the mechanical requirements, material compatibility, and environmental exposure of the final product.

Advantages and Limitations of Each Method

Brazing offers strong, heat-resistant joints suitable for high-temperature applications, with advantages including excellent mechanical strength and the ability to join dissimilar metals. Limitations involve the need for precise temperature control and potential thermal distortion of components. Bonding provides flexibility in material selection and surface compatibility, creating joints with good fatigue resistance and minimal thermal impact, but its limitations include lower strength compared to brazing and sensitivity to environmental factors such as moisture and temperature changes.

Choosing the Right Joining Technique

Brazing offers a strong, metal-to-metal joint ideal for high-temperature and high-strength applications, using a filler metal with a melting point above 450degC to create durable, corrosion-resistant bonds. Bonding, which includes adhesives like epoxies and acrylics, is preferred for joining dissimilar materials, providing flexibility, vibration damping, and resistance to environmental factors without the need for heat. Selecting the right joining technique depends on factors such as material type, load requirements, operating temperature, and environmental exposure to ensure optimal performance and longevity of the assembly.

Brazing Infographic

libterm.com

libterm.com