M12 connectors provide a robust and reliable solution for industrial automation and sensor applications, featuring compact design and secure locking mechanisms. Their versatility in handling signal, data, and power transmissions makes them essential for maintaining efficient and stable operations in harsh environments. Discover how M12 connectors can enhance your system's performance and durability by reading the full article.

Table of Comparison

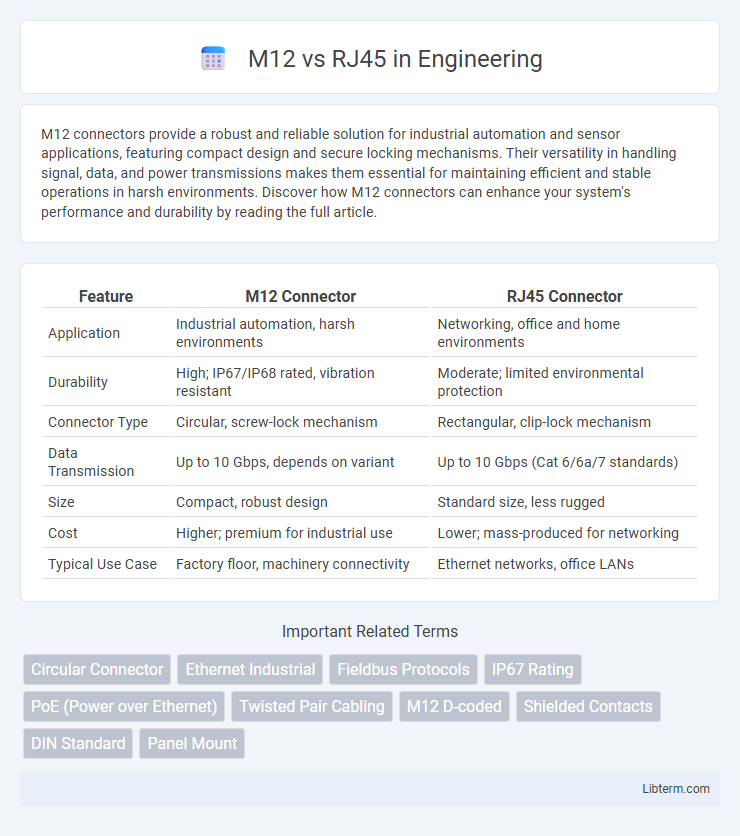

| Feature | M12 Connector | RJ45 Connector |

|---|---|---|

| Application | Industrial automation, harsh environments | Networking, office and home environments |

| Durability | High; IP67/IP68 rated, vibration resistant | Moderate; limited environmental protection |

| Connector Type | Circular, screw-lock mechanism | Rectangular, clip-lock mechanism |

| Data Transmission | Up to 10 Gbps, depends on variant | Up to 10 Gbps (Cat 6/6a/7 standards) |

| Size | Compact, robust design | Standard size, less rugged |

| Cost | Higher; premium for industrial use | Lower; mass-produced for networking |

| Typical Use Case | Factory floor, machinery connectivity | Ethernet networks, office LANs |

Overview of M12 and RJ45 Connectors

M12 connectors offer a robust, circular design commonly used in industrial automation for secure, vibration-resistant connections, supporting Ethernet and sensor interfaces. RJ45 connectors, recognized for their rectangular shape, are the standard in networking for Ethernet cables, facilitating high-speed data transmission in office and data center environments. The M12's rugged construction contrasts with RJ45's widespread adoption in commercial networking, highlighting their distinct applications in heavy-duty versus standard connectivity scenarios.

Key Differences Between M12 and RJ45

M12 connectors feature a circular design with robust metal housing suited for harsh industrial environments, whereas RJ45 connectors have a rectangular shape commonly used in standard Ethernet networks. M12 connectors support higher ingress protection ratings (IP67/IP68), ensuring superior resistance to dust and water, unlike RJ45 connectors that typically lack such sealing capabilities. Data transmission capabilities also differ, with RJ45 widely supporting speeds up to 10 Gbps over twisted pair cables, while M12 connectors are optimized for rugged applications with a balance of durability and data performance typically up to 1 Gbps.

Physical Design and Durability

M12 connectors feature a compact, circular design that offers enhanced resistance to dust, water, and vibration, making them ideal for harsh industrial environments. RJ45 connectors have a rectangular shape commonly used in standard Ethernet cables but lack the robust sealing and ruggedness of M12 connectors. M12's robust metal housing and locking mechanism provide superior durability and secure connections compared to the plastic clip design of RJ45 connectors.

Data Transmission Speed and Performance

M12 connectors support data transmission speeds up to 10 Gbps, typically used in industrial Ethernet applications requiring robust and reliable connections in harsh environments. RJ45 connectors, standard for Ethernet networks, commonly handle speeds up to 1 Gbps with Category 5e cables and up to 10 Gbps with Category 6a cables, suitable for general office and data center deployments. Performance-wise, M12 connectors offer superior resistance to vibration, dust, and moisture, ensuring stable high-speed data transfer in demanding conditions compared to the more vulnerable RJ45 connectors.

Applications in Industrial Environments

M12 connectors are preferred in industrial environments for their robust, waterproof, and vibration-resistant design, making them ideal for factory automation, machinery, and harsh outdoor conditions. RJ45 connectors are commonly used in less demanding industrial applications like office networking and basic Ethernet connections due to their widespread compatibility and ease of use. Selecting M12 over RJ45 enhances reliability in environments exposed to dust, moisture, and mechanical stress, critical for maintaining continuous industrial operations.

Ease of Installation and Maintenance

M12 connectors offer robust, compact designs suitable for harsh industrial environments, enabling straightforward installation with fewer tools and reduced space requirements compared to RJ45 connectors. RJ45 connectors are widely used in standard Ethernet applications and offer easier cable termination but may require additional protective measures in industrial settings to ensure durability. Maintenance on M12 systems tends to be more efficient due to their rugged construction, minimizing downtime in demanding conditions compared to the more delicate RJ45 connectors.

Connectivity and Network Compatibility

M12 connectors provide robust, industrial-grade connectivity designed for harsh environments with secure locking mechanisms and IP67/IP68 ratings, ensuring reliable network performance in factory automation and outdoor applications. RJ45 connectors are widely used for commercial Ethernet networks, offering broad compatibility with Cat5e, Cat6, and Cat6a cables to support high-speed data transmission in office and residential settings. While RJ45 is the standard for general networking, M12 excels in environments requiring vibration resistance, waterproofing, and durable connections for Ethernet-based protocols like PROFINET and EtherNet/IP.

Environmental Resistance and Protection Ratings

M12 connectors offer superior environmental resistance compared to RJ45 connectors, featuring IP67 and higher protection ratings that ensure dust-tight and water-immersion proof performance, making them ideal for harsh industrial environments. In contrast, RJ45 connectors typically provide lower protection levels, usually IP20, which limits their suitability to indoor or controlled settings. The robust sealing and ruggedized design of M12 connectors enable reliable operation in extreme temperatures, vibrations, and exposure to chemicals, enhancing their durability in demanding applications.

Cost Comparison: M12 vs RJ45

M12 connectors typically incur higher costs than RJ45 due to their robust design and industrial-grade materials, making them suitable for harsh environments. RJ45 connectors are more cost-effective and widely used in standard networking applications, benefiting from mass production economies. While M12 offers durability and reliability in demanding conditions, RJ45 remains the budget-friendly choice for general Ethernet connectivity.

Choosing the Right Connector for Your Application

Choosing between M12 and RJ45 connectors depends on the application's environmental conditions and performance requirements. M12 connectors offer robust, IP67-rated protection ideal for industrial and harsh environments, while RJ45 connectors are widely used for standard Ethernet connections in office or less demanding settings. Prioritize M12 for vibration resistance and secure locking, and RJ45 for ease of use and broad compatibility in network infrastructure.

M12 Infographic

libterm.com

libterm.com