Stepper motors provide precise control of rotational movement by converting digital pulses into incremental shaft positions. Their ability to offer high torque at low speeds without feedback systems makes them ideal for applications like 3D printers, CNC machines, and robotics. Discover how optimizing stepper motor settings can enhance your project's performance by reading further in the article.

Table of Comparison

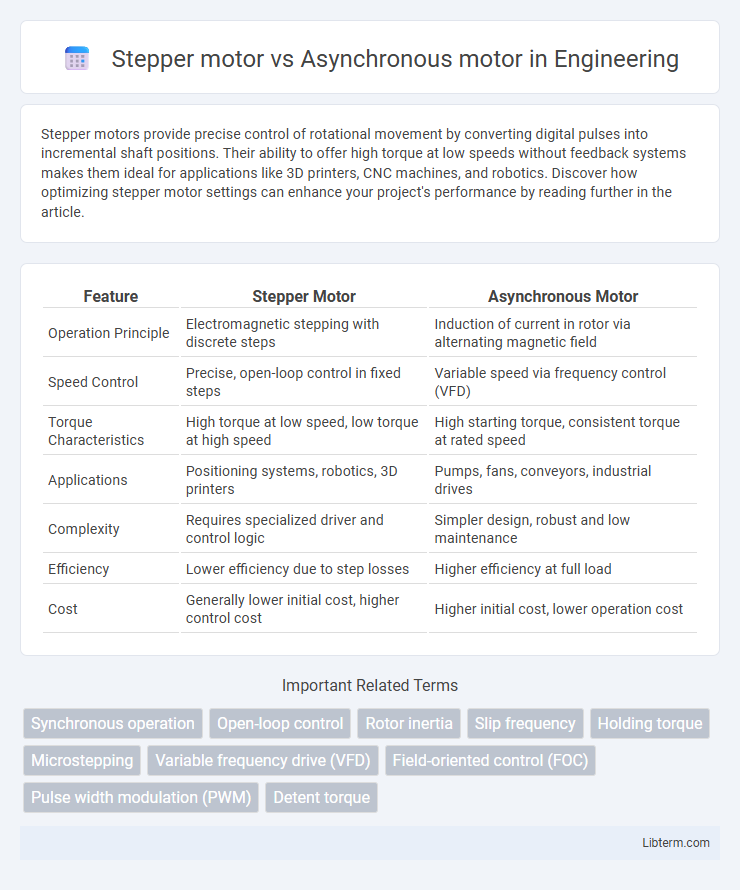

| Feature | Stepper Motor | Asynchronous Motor |

|---|---|---|

| Operation Principle | Electromagnetic stepping with discrete steps | Induction of current in rotor via alternating magnetic field |

| Speed Control | Precise, open-loop control in fixed steps | Variable speed via frequency control (VFD) |

| Torque Characteristics | High torque at low speed, low torque at high speed | High starting torque, consistent torque at rated speed |

| Applications | Positioning systems, robotics, 3D printers | Pumps, fans, conveyors, industrial drives |

| Complexity | Requires specialized driver and control logic | Simpler design, robust and low maintenance |

| Efficiency | Lower efficiency due to step losses | Higher efficiency at full load |

| Cost | Generally lower initial cost, higher control cost | Higher initial cost, lower operation cost |

Introduction to Stepper Motors and Asynchronous Motors

Stepper motors operate by dividing a full rotation into equal steps, allowing precise control of angular position without feedback systems, making them ideal for applications requiring accurate positioning. Asynchronous motors, also known as induction motors, rely on electromagnetic induction to generate torque and are widely used in industrial applications due to their ruggedness, simplicity, and cost-effectiveness. The key distinction lies in stepper motors providing discrete rotational steps, while asynchronous motors deliver continuous rotation with speed dependent on load and supply frequency.

Basic Working Principles

Stepper motors operate by dividing a full rotation into a number of equal steps, using electromagnetic coils that are energized sequentially to create precise angular movement. Asynchronous motors, also known as induction motors, work based on electromagnetic induction where the rotor follows the rotating magnetic field generated by the stator at a speed slightly less than the synchronous speed. The stepper motor provides high-precision positioning by controlled pulses, while the asynchronous motor delivers continuous rotation through induced current without direct electrical connections to the rotor.

Key Structural Differences

Stepper motors feature multiple coils organized in phases around a rotor with permanent magnets or variable reluctance, allowing precise control through discrete steps, whereas asynchronous motors have a squirrel cage rotor and operate on alternating current inducing rotor currents for rotation. Stepper motors typically exhibit a compact stator with specialized windings enabling incremental movement, while asynchronous motors possess a robust laminated stator core designed for continuous rotation and higher power output. The fundamental structural distinction lies in the rotor design: stepper motors rely on magnetic positions for incremental angles, contrasting with the induction principle driving the rotor in asynchronous motors.

Performance Characteristics

Stepper motors provide precise position control with high torque at low speeds, making them ideal for applications requiring accurate movement and repeatability. Asynchronous motors deliver efficient operation over a wide range of speeds, offering high starting torque and smooth performance in industrial environments. The inherent design of stepper motors supports open-loop control, whereas asynchronous motors often require feedback systems for precise speed regulation.

Control Mechanisms

Stepper motors utilize precise digital pulse signals to control position and speed, enabling accurate open-loop control without feedback systems. Asynchronous motors rely on varying frequency and voltage through inverters for speed regulation, often requiring closed-loop feedback for precise control. The distinct control mechanisms make stepper motors ideal for applications demanding exact positioning, while asynchronous motors excel in continuous rotation with variable speed.

Precision and Accuracy

Stepper motors offer superior precision and accuracy due to their design, which allows for controlled, discrete step movements with precise angular positioning typically ranging from 0.9deg to 1.8deg per step. Asynchronous motors, or induction motors, lack inherent position control and rely on external sensors or encoders for feedback, resulting in less direct accuracy and lower precision in positioning tasks. The inherent open-loop operation of stepper motors makes them ideal for applications demanding high positional accuracy without complex control systems, unlike asynchronous motors that excel in continuous rotation scenarios with moderate precision requirements.

Typical Applications

Stepper motors are commonly used in precise control applications such as 3D printers, CNC machines, and robotics where accurate positioning is crucial. Asynchronous motors, also known as induction motors, dominate industrial applications like pumps, fans, conveyors, and compressors due to their robustness and efficiency in continuous operation. Stepper motors excel in low-speed, high-torque tasks requiring exact movements, while asynchronous motors are preferred for high-power, variable-speed machinery in manufacturing and HVAC systems.

Advantages and Disadvantages

Stepper motors offer precise position control and excellent torque at low speeds, making them ideal for applications requiring accurate movement, but they can suffer from resonance issues and lower power efficiency. Asynchronous motors provide robust performance, high efficiency, and cost-effectiveness for continuous operation, yet they lack the precise control and torque at low speeds that stepper motors deliver. Choosing between the two depends on the specific needs for precision versus power efficiency in industrial or automation tasks.

Energy Efficiency Comparison

Stepper motors typically consume more energy due to constant current draw regardless of load, leading to lower energy efficiency compared to asynchronous motors. Asynchronous motors operate with variable efficiency, often achieving higher energy savings by adjusting power consumption based on load conditions. In industrial applications, asynchronous motors are generally preferred for energy efficiency, while stepper motors are favored for precision despite higher energy use.

Choosing the Right Motor for Your Needs

Choosing the right motor depends on the specific application requirements: stepper motors offer precise position control and are ideal for low-speed, high-precision tasks like CNC machinery and robotics, while asynchronous motors (induction motors) provide robust, efficient performance for continuous operation in industrial equipment and pumps. Stepper motors operate on a digital step angle principle, ensuring repeatable accuracy without feedback, whereas asynchronous motors run on AC power with slip between the rotor and stator fields for smooth, reliable power delivery. Understanding torque demands, speed variations, and control complexity helps determine whether a stepper motor's exact positioning or an asynchronous motor's durability better suits your project.

Stepper motor Infographic

libterm.com

libterm.com