Steady flow describes a fluid motion where velocity remains constant at every point over time, ensuring predictable and uniform movement. This concept is crucial in engineering applications such as pipeline design and aerodynamics to maintain system efficiency and safety. Discover more about steady flow principles and their practical implications in the following article.

Table of Comparison

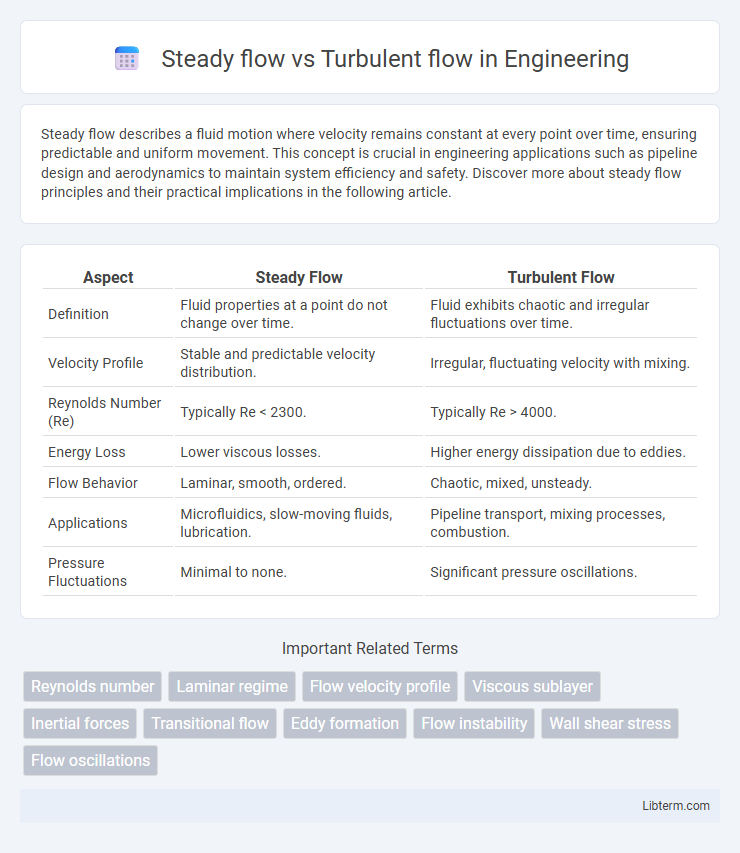

| Aspect | Steady Flow | Turbulent Flow |

|---|---|---|

| Definition | Fluid properties at a point do not change over time. | Fluid exhibits chaotic and irregular fluctuations over time. |

| Velocity Profile | Stable and predictable velocity distribution. | Irregular, fluctuating velocity with mixing. |

| Reynolds Number (Re) | Typically Re < 2300. | Typically Re > 4000. |

| Energy Loss | Lower viscous losses. | Higher energy dissipation due to eddies. |

| Flow Behavior | Laminar, smooth, ordered. | Chaotic, mixed, unsteady. |

| Applications | Microfluidics, slow-moving fluids, lubrication. | Pipeline transport, mixing processes, combustion. |

| Pressure Fluctuations | Minimal to none. | Significant pressure oscillations. |

Understanding Fluid Flow: An Introduction

Steady flow occurs when fluid particles move along fixed paths with constant velocity at any given point, ensuring predictable and uniform motion. Turbulent flow is characterized by chaotic fluid movement with rapid fluctuations in velocity and pressure, leading to mixing and increased energy loss. Understanding fluid flow requires analyzing Reynolds number, which predicts the transition from steady (laminar) to turbulent flow in pipes or open channels.

What is Steady Flow?

Steady flow refers to a fluid movement where velocity at any given point remains constant over time, ensuring predictable and uniform behavior. It is characterized by smooth streamlines and minimal mixing between fluid layers, which reduces energy losses and maintains flow stability. This type of flow is commonly observed in well-controlled pipelines and laminar flow conditions within engineering systems.

What is Turbulent Flow?

Turbulent flow is characterized by chaotic fluid motion with irregular fluctuations and eddies, resulting from high flow velocities or obstacles disrupting smooth streamlines. It contrasts with steady flow, where fluid particles follow orderly paths without significant mixing or disturbances. Turbulent flow enhances mixing and increases frictional resistance, impacting engineering applications such as pipeline design and aerodynamic performance.

Key Differences Between Steady and Turbulent Flow

Steady flow is characterized by fluid particles moving along fixed paths with constant velocity at any given point, resulting in predictable and orderly motion, while turbulent flow exhibits chaotic fluctuations and irregular velocity variations throughout the fluid. In steady flow, parameters such as velocity, pressure, and cross-sectional area remain constant over time, whereas turbulent flow involves rapid changes in these parameters and intense mixing caused by eddies and vortices. The Reynolds number, a dimensionless quantity, is a key factor distinguishing the two; low Reynolds numbers indicate steady laminar flow, while high Reynolds numbers correspond to turbulent flow.

Characteristics of Steady Flow

Steady flow is characterized by constant fluid velocity and pressure at any given point, ensuring that flow parameters do not change over time. This type of flow maintains laminar streamlines, minimizing fluctuations and turbulence within the fluid. Engineers often prefer steady flow in systems requiring predictable and stable fluid behavior, such as in pipeline transport and HVAC designs.

Features of Turbulent Flow

Turbulent flow is characterized by chaotic and irregular fluid motion, featuring fluctuating velocities and eddies of various sizes throughout the flow field. It exhibits high momentum diffusion and increased energy dissipation due to intense mixing, resulting in enhanced heat and mass transfer rates compared to steady flow. This flow regime typically occurs at high Reynolds numbers exceeding 4000, where inertial forces dominate over viscous forces, causing flow instabilities and vortices.

Factors Affecting Flow Type

Flow type in fluid dynamics is influenced by Reynolds number, which depends on fluid velocity, characteristic length, and kinematic viscosity. Higher velocities or larger characteristic lengths increase Reynolds number, leading to turbulent flow, while lower values favor steady or laminar flow. Surface roughness and fluid temperature also affect flow stability, with rougher surfaces and higher temperatures promoting turbulence.

Practical Examples in Engineering and Nature

Steady flow occurs in pipelines delivering water to homes where velocity remains constant over time, ensuring predictable pressure and efficient system design. Turbulent flow is common in river rapids or air circulation around aircraft wings, characterized by chaotic fluctuations that impact drag and heat transfer. Understanding these flow types helps engineers optimize fluid transport, cooling systems, and aerodynamic performance in practical applications.

Advantages and Disadvantages of Each Flow

Steady flow offers the advantage of predictable velocity and pressure at any point, facilitating precise engineering calculations and efficient system design, but it may not effectively mix fluids or dissipate energy in natural systems. Turbulent flow enhances mixing, heat transfer, and momentum exchange, making it beneficial for combustion and chemical reactors, yet it causes higher frictional losses, increased wear on components, and complex flow patterns that are harder to model. Understanding the trade-offs between steady and turbulent flow is crucial for optimizing fluid systems in applications ranging from pipelines to aerodynamic surfaces.

Applications and Importance in Industry

Steady flow ensures predictable fluid behavior crucial for chemical processing, HVAC systems, and pipeline transport where consistent pressure and velocity are essential. Turbulent flow enhances mixing, heat transfer, and reaction rates, making it vital for combustion engines, wastewater treatment, and industrial mixers. Understanding flow regimes optimizes system efficiency, safety, and product quality across various engineering applications.

Steady flow Infographic

libterm.com

libterm.com