The thermoelectric effect enables the direct conversion of temperature differences into electric voltage and vice versa, playing a crucial role in energy harvesting and cooling technologies. This phenomenon involves three key effects: the Seebeck effect, Peltier effect, and Thomson effect, each contributing uniquely to thermoelectric applications. Explore the rest of the article to understand how your devices can benefit from thermoelectric innovations.

Table of Comparison

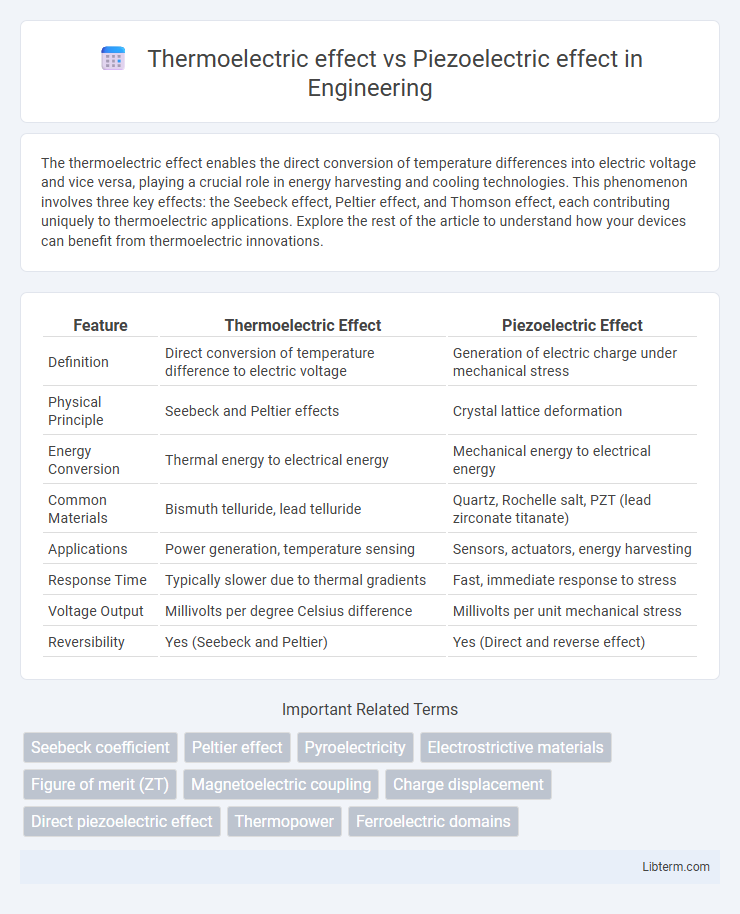

| Feature | Thermoelectric Effect | Piezoelectric Effect |

|---|---|---|

| Definition | Direct conversion of temperature difference to electric voltage | Generation of electric charge under mechanical stress |

| Physical Principle | Seebeck and Peltier effects | Crystal lattice deformation |

| Energy Conversion | Thermal energy to electrical energy | Mechanical energy to electrical energy |

| Common Materials | Bismuth telluride, lead telluride | Quartz, Rochelle salt, PZT (lead zirconate titanate) |

| Applications | Power generation, temperature sensing | Sensors, actuators, energy harvesting |

| Response Time | Typically slower due to thermal gradients | Fast, immediate response to stress |

| Voltage Output | Millivolts per degree Celsius difference | Millivolts per unit mechanical stress |

| Reversibility | Yes (Seebeck and Peltier) | Yes (Direct and reverse effect) |

Introduction to Thermoelectric and Piezoelectric Effects

Thermoelectric effects involve the direct conversion of temperature differences into electric voltage and vice versa, primarily observed in materials with high Seebeck coefficients such as bismuth telluride and lead telluride. Piezoelectric effects arise in non-centrosymmetric crystals like quartz and zinc oxide, where mechanical stress induces an electric charge due to the displacement of electric dipoles. Both effects are exploited in energy harvesting, sensing, and actuation applications, with thermoelectrics focusing on heat-to-electricity conversion and piezoelectrics on mechanical-to-electric energy transduction.

Basic Principles of the Thermoelectric Effect

The thermoelectric effect involves the direct conversion of temperature differences into electric voltage through the Seebeck effect, where charge carriers in a material move from the hot side to the cold side, generating an electric potential. This principle contrasts with the piezoelectric effect, which produces electric charge in response to mechanical stress rather than thermal gradients. Thermoelectric materials, such as bismuth telluride and lead telluride, are critical for applications in power generation and refrigeration by exploiting temperature gradients to create electrical energy.

Fundamental Concepts of the Piezoelectric Effect

The piezoelectric effect is the ability of certain materials, such as quartz and Rochelle salt, to generate an electric charge in response to applied mechanical stress, resulting from the displacement of ions within the crystal lattice. Unlike the thermoelectric effect, which involves voltage generation due to temperature differences, the piezoelectric effect relies on mechanical deformation and anisotropic crystal structures with non-centrosymmetric symmetry. This fundamental property enables the use of piezoelectric materials in sensors, actuators, and energy harvesting devices that convert mechanical signals into electrical responses.

Key Differences: Thermoelectric vs Piezoelectric Mechanisms

The thermoelectric effect generates voltage through temperature differences, converting heat energy into electrical energy using materials like bismuth telluride. The piezoelectric effect produces electric charge by mechanical stress or pressure applied to certain crystals such as quartz or Rochelle salt. Thermoelectric mechanisms rely on electron and hole diffusion driven by temperature gradients, while piezoelectric mechanisms depend on crystal lattice deformation altering electrical polarization.

Materials Used in Thermoelectric and Piezoelectric Devices

Thermoelectric devices primarily use materials such as bismuth telluride, lead telluride, and silicon-germanium alloys for efficient heat-to-electricity conversion due to their high Seebeck coefficients and low thermal conductivity. Piezoelectric devices commonly utilize materials like quartz, lead zirconate titanate (PZT), and zinc oxide, which exhibit strong electromechanical coupling and generate electric charge under mechanical stress. The material selection in both effects focuses on optimizing energy conversion efficiency through intrinsic physical properties tailored to specific thermal or mechanical stimuli.

Energy Conversion Applications

The thermoelectric effect converts temperature differences directly into electrical voltage, enabling waste heat recovery systems and power generation in remote locations. The piezoelectric effect generates electric charge from mechanical stress, widely used in energy harvesting from vibrations and pressure changes in sensors and wearable devices. Both effects provide innovative energy conversion solutions, with thermoelectrics excelling in thermal-to-electric energy transformation and piezoelectrics in mechanical-to-electrical energy conversion.

Efficiency and Performance Comparison

The thermoelectric effect converts temperature differences directly into electrical voltage with efficiency typically limited by the material's figure of merit (ZT), often achieving 5-8% for commercial devices, while piezoelectric effect generates electrical charge from mechanical stress with high energy conversion efficiency in dynamic applications. Thermoelectric devices excel in steady-state thermal gradients but suffer from lower power densities compared to piezoelectric systems, which provide rapid response and higher power output in mechanical vibration harvesting. Optimization of thermoelectric materials (like Bi2Te3) focuses on enhancing Seebeck coefficients and reducing thermal conductivity, whereas piezoelectric performance hinges on material properties like coupling coefficients (e.g., PZT ceramics), making each effect suitable for distinct energy harvesting scenarios.

Advantages and Limitations of Each Effect

The thermoelectric effect offers the advantage of direct conversion between thermal and electrical energy, enabling waste heat recovery and solid-state cooling, but is limited by relatively low efficiency and material costs. The piezoelectric effect provides efficient energy harvesting from mechanical vibrations and precise sensing capabilities, yet it is constrained by the need for mechanical stress and material fatigue over time. Both effects find specialized applications, with thermoelectric devices excelling in temperature gradient environments and piezoelectric materials suited for dynamic pressure or vibration-based energy conversion.

Real-World Uses and Industry Applications

The thermoelectric effect is widely utilized in power generation and temperature control, especially in automotive waste heat recovery systems and portable coolers for medical equipment. The piezoelectric effect finds significant applications in sensors and actuators, such as in precision medical ultrasound imaging, industrial non-destructive testing, and energy harvesting from mechanical vibrations in wearable devices. Both effects enable innovative energy-efficient solutions, with thermoelectric devices leveraging electron flow for heat-to-electricity conversion and piezoelectric materials converting mechanical stress into electric signals in diverse industries.

Future Prospects and Research Directions

Emerging research in thermoelectric materials focuses on enhancing energy conversion efficiency through nanostructuring and novel compound synthesis, aiming to develop eco-friendly power generators and wearable devices. Piezoelectric effect advancements prioritize flexible and biocompatible materials for next-generation sensors, energy harvesting, and medical implants, emphasizing scalable manufacturing techniques. Future prospects include hybrid systems integrating thermoelectric and piezoelectric functionalities to maximize energy scavenging from diverse environmental sources.

Thermoelectric effect Infographic

libterm.com

libterm.com