The Stirling cycle refrigeration system utilizes a closed-cycle regenerative heat engine for cooling purposes, achieving high efficiency and reduced environmental impact compared to traditional refrigerants. Its unique mechanism relies on the cyclic compression and expansion of gas, allowing for precise temperature control and energy savings. Discover how this innovative refrigeration technology can enhance your cooling solutions throughout the rest of the article.

Table of Comparison

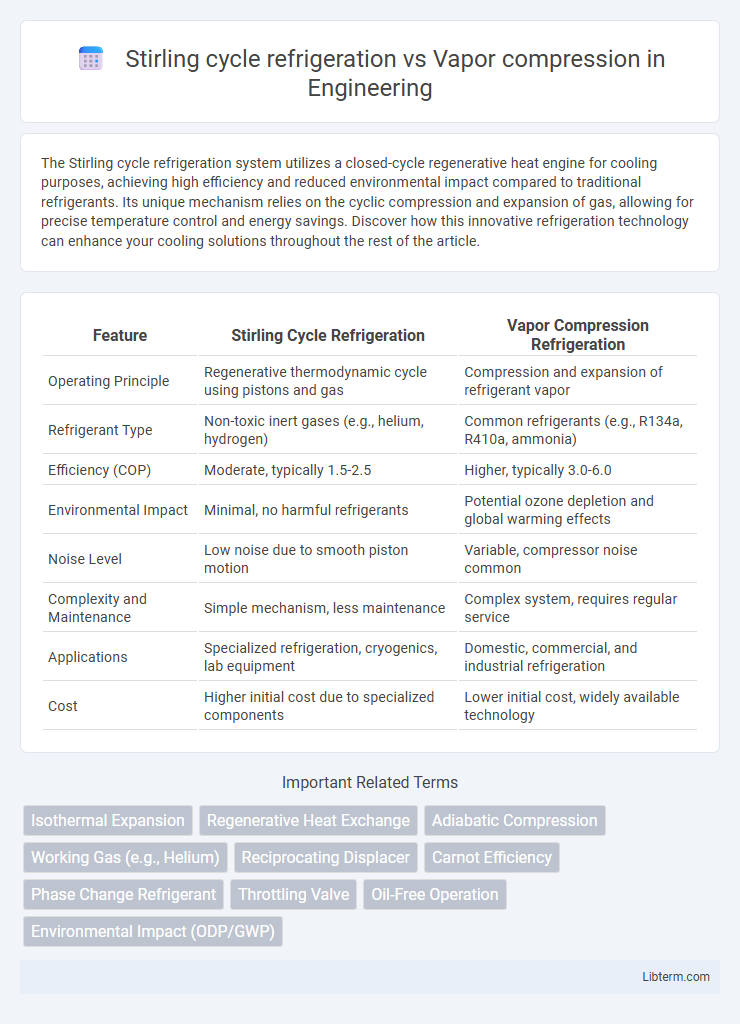

| Feature | Stirling Cycle Refrigeration | Vapor Compression Refrigeration |

|---|---|---|

| Operating Principle | Regenerative thermodynamic cycle using pistons and gas | Compression and expansion of refrigerant vapor |

| Refrigerant Type | Non-toxic inert gases (e.g., helium, hydrogen) | Common refrigerants (e.g., R134a, R410a, ammonia) |

| Efficiency (COP) | Moderate, typically 1.5-2.5 | Higher, typically 3.0-6.0 |

| Environmental Impact | Minimal, no harmful refrigerants | Potential ozone depletion and global warming effects |

| Noise Level | Low noise due to smooth piston motion | Variable, compressor noise common |

| Complexity and Maintenance | Simple mechanism, less maintenance | Complex system, requires regular service |

| Applications | Specialized refrigeration, cryogenics, lab equipment | Domestic, commercial, and industrial refrigeration |

| Cost | Higher initial cost due to specialized components | Lower initial cost, widely available technology |

Introduction to Refrigeration Technologies

Stirling cycle refrigeration utilizes a closed regenerative thermodynamic cycle employing a working gas for heat transfer, offering high efficiency and low environmental impact compared to traditional vapor compression systems. Vapor compression refrigeration relies on phase change of refrigerants in a compression-expansion cycle, widely adopted due to its established technology, cost-effectiveness, and capacity for various cooling loads. Advances in Stirling technology emphasize reduced greenhouse gas emissions and enhanced performance in niche applications, contrasting with the ubiquitous use and refrigerant-related challenges of vapor compression systems.

Overview of the Stirling Cycle Refrigeration

The Stirling cycle refrigeration system operates by cyclic compression and expansion of a working gas, typically helium, to transfer heat efficiently without the use of phase changes. This closed-cycle system provides precise temperature control and low noise levels, making it ideal for cryogenic and scientific applications. Unlike vapor compression systems that rely on refrigerant phase transitions, the Stirling cycle offers environmentally friendly operation with reduced emissions and minimal oil contamination.

Fundamentals of Vapor Compression Refrigeration

Vapor compression refrigeration operates on the principle of compressing a refrigerant vapor to high pressure, condensing it into a liquid, and then expanding it to absorb heat in the evaporator, making it highly efficient for cooling applications. Unlike Stirling cycle refrigeration, which utilizes cyclic compression and expansion of a working gas to produce cooling, vapor compression systems rely on phase changes and the thermodynamic properties of refrigerants. The fundamentals of vapor compression include key components such as the compressor, condenser, expansion valve, and evaporator, enabling effective heat transfer and temperature control in commercial and industrial refrigeration.

Thermodynamic Principles Compared

The Stirling cycle refrigeration system operates on a closed regenerative thermodynamic cycle using an external heat source, relying on cyclic compression and expansion of gas to transfer heat. In contrast, vapor compression refrigeration exploits phase changes of a refrigerant within a closed circuit, utilizing evaporation and condensation to absorb and release heat. Thermodynamically, Stirling refrigeration achieves high efficiency through reversible isothermal and isochoric processes, while vapor compression relies on adiabatic compression and isobaric heat exchange, influencing their respective coefficients of performance and application suitability.

Efficiency and Performance Metrics

Stirling cycle refrigeration systems often achieve higher thermodynamic efficiency due to their external combustion process and regenerative heat exchange, leading to improved coefficient of performance (COP) in low-temperature applications. Vapor compression systems dominate commercial refrigeration with COP values typically ranging from 3 to 6, benefiting from well-established compressor and refrigerant technologies that optimize performance under varying load conditions. While Stirling cycle units excel in specific niche uses requiring quiet and low-vibration operation, vapor compression remains more adaptable and cost-effective for large-scale, continuous refrigeration needs.

Environmental Impact and Sustainability

Stirling cycle refrigeration operates with inert gases and relies on external heat sources, resulting in zero direct greenhouse gas emissions and reduced environmental impact compared to conventional vapor compression systems, which utilize hydrofluorocarbon (HFC) refrigerants known for high global warming potential. The closed-loop design of Stirling refrigerators minimizes refrigerant leakage, enhancing sustainability by promoting longer equipment lifespans and lower maintenance demands. Vapor compression technology, while widely adopted, faces ongoing challenges in transitioning to eco-friendly refrigerants and improving energy efficiency to meet evolving environmental regulations.

Application Areas and Practical Use Cases

Stirling cycle refrigeration is primarily used in cryogenic applications such as liquefying gases, scientific research, and space technology due to its low vibration and high reliability at extremely low temperatures. Vapor compression refrigeration dominates commercial and residential cooling systems, including air conditioners, refrigerators, and heat pumps, because of its higher efficiency and widespread availability of refrigerants. Practical use cases for Stirling coolers include aerospace instruments and superconducting magnet cooling, whereas vapor compression systems are preferred for everyday refrigeration and HVAC applications.

Maintenance and Operational Considerations

Stirling cycle refrigeration systems require less frequent maintenance due to their external combustion and sealed system design, reducing risks of refrigerant leaks and compressor wear common in vapor compression units. Vapor compression systems often involve more complex components like compressors, expansion valves, and refrigerant handling, leading to higher maintenance costs and operational downtime. Operationally, Stirling systems offer quieter performance and greater durability under varying load conditions, while vapor compression units provide faster cooling cycles but necessitate vigilant monitoring of refrigerant levels and compressor health for optimal efficiency.

Cost Analysis: Stirling vs Vapor Compression

Stirling cycle refrigeration systems exhibit higher initial costs due to complex mechanical components and precision manufacturing requirements compared to vapor compression systems, which benefit from established mass production techniques. Operational expenses for Stirling units can be lower in niche applications due to their higher efficiency and use of inert gases, whereas vapor compression systems often incur greater maintenance costs linked to refrigerant handling and frequent component replacements. Life cycle cost analysis frequently favors vapor compression in large-scale, conventional refrigeration due to lower upfront investment despite higher operational expenses.

Future Trends in Refrigeration Technology

Stirling cycle refrigeration offers advantages in energy efficiency and environmentally friendly operation by using inert gases and sealed systems, making it a promising option for ultra-low temperature applications in the future. Vapor compression refrigeration remains dominant due to its proven reliability and cost-effectiveness, but future trends focus on integrating eco-friendly refrigerants with low global warming potential (GWP) and advanced control systems to enhance performance and reduce emissions. Emerging technologies combine Stirling and vapor compression principles to develop hybrid systems that optimize efficiency, sustainability, and adaptability in refrigeration technology.

Stirling cycle refrigeration Infographic

libterm.com

libterm.com