Arch dams efficiently transfer water pressure to the canyon walls, making them ideal for narrow, rocky locations. Their curved design uses natural rock formations to withstand immense forces, ensuring structural stability and durability. Explore the rest of the article to understand how arch dams can benefit your hydroelectric or water management projects.

Table of Comparison

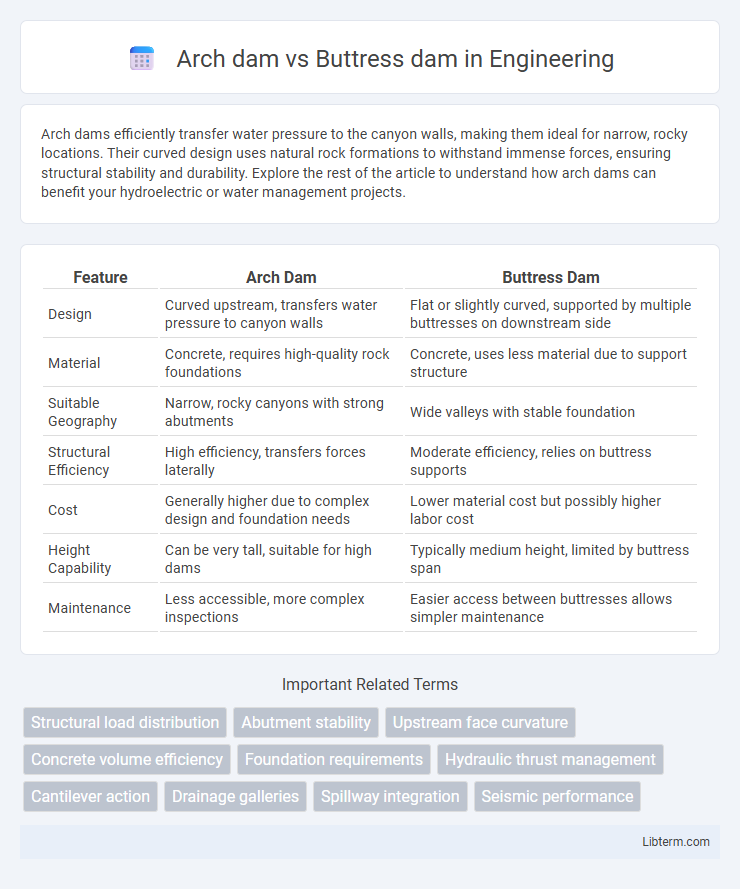

| Feature | Arch Dam | Buttress Dam |

|---|---|---|

| Design | Curved upstream, transfers water pressure to canyon walls | Flat or slightly curved, supported by multiple buttresses on downstream side |

| Material | Concrete, requires high-quality rock foundations | Concrete, uses less material due to support structure |

| Suitable Geography | Narrow, rocky canyons with strong abutments | Wide valleys with stable foundation |

| Structural Efficiency | High efficiency, transfers forces laterally | Moderate efficiency, relies on buttress supports |

| Cost | Generally higher due to complex design and foundation needs | Lower material cost but possibly higher labor cost |

| Height Capability | Can be very tall, suitable for high dams | Typically medium height, limited by buttress span |

| Maintenance | Less accessible, more complex inspections | Easier access between buttresses allows simpler maintenance |

Introduction to Arch Dams and Buttress Dams

Arch dams are curved structures designed to transfer water pressure primarily to the abutments, making them highly efficient for narrow, rocky canyons with strong side walls. Buttress dams use a series of supports, or buttresses, on the downstream side to resist water pressure, allowing for reduced material use compared to gravity dams. The selection between arch and buttress dams depends on geological conditions, material availability, and design requirements for stability and cost-efficiency.

Structural Design and Principles

Arch dams rely on a curved design that transfers water pressure horizontally into the canyon walls, utilizing compressive forces for stability and requiring strong abutments. Buttress dams employ a series of triangular supports on the downstream side, distributing water loads through buttresses to the foundation, allowing for reduced material use compared to gravity dams. Structural efficiency in arch dams depends on narrow, rocky gorges, while buttress dams are suitable for wider valleys with less ideal foundations.

Materials Used in Construction

Arch dams primarily use high-strength concrete designed to efficiently transfer water pressure to the abutments, requiring less material due to their curved structure. Buttress dams utilize reinforced concrete supported by a series of triangular buttresses, enabling reduced material volume compared to gravity dams while maintaining structural integrity. The choice of materials in both dam types depends on site-specific geological conditions, with arch dams favoring strong rock foundations and buttress dams suitable for broader valleys with varying substrata.

Site Selection Criteria

Arch dams require narrow, rocky gorges with strong abutments to effectively transfer water pressure through their curved structure, making geological stability and steep canyon walls critical site selection criteria. Buttress dams are more adaptable to wider valleys with less solid foundations, as their design distributes water load across multiple supports, prioritizing moderate geology and availability of construction materials. Both dam types necessitate thorough hydrological analysis and seismic stability assessments to ensure structural integrity and long-term safety.

Load Distribution and Stability

Arch dams transfer water pressure primarily by directing loads into the adjacent rock walls through their curved design, resulting in efficient load distribution and high stability in narrow, rocky gorges. Buttress dams distribute loads across multiple supports or buttresses, allowing the structure to handle thrust by transferring forces directly to the foundation, offering stability in wide valleys with less strong abutments. The arch dam's reliance on compressive forces contrasts with the buttress dam's framework that reduces material usage while maintaining structural integrity through multiple load transfer points.

Construction Process and Techniques

Arch dams are constructed by curving upstream to transfer water pressure into the adjacent rock walls through compression, requiring strong abutments and precise geometric shaping, often involving complex formwork and concrete pouring in narrow valleys. Buttress dams use a series of triangular supports (buttresses) on the downstream side to hold the dam face, enabling thinner walls and reduced material use, with construction focusing on assembling the face slabs and buttresses, often employing modular concrete segments and scaffolding. The choice between these methods depends on site geology, valley shape, and material availability, with arch dams favored in narrow, rocky locations and buttress dams suitable for wider valleys and less resistant foundations.

Cost Comparison and Economic Factors

Arch dams generally incur higher initial construction costs due to their complex engineering and requirement for strong, narrow canyon sites, but their efficient material use often results in lower long-term maintenance expenses. Buttress dams tend to have lower upfront costs because of simpler construction techniques and adaptable site requirements, yet they may involve higher maintenance and inspection costs over time. Economic factors such as site geology, availability of construction materials, and long-term operational expenses heavily influence the cost-effectiveness between arch and buttress dams.

Advantages and Disadvantages

Arch dams offer high strength and efficiency by transferring water pressure to canyon walls, making them ideal for narrow, rocky locations but require strong geological foundations and complex engineering. Buttress dams use multiple supports to reduce material usage and weight, suitable for wider valleys with weaker foundations, yet they are more expensive and require extensive maintenance due to numerous structural elements. Both dam types demand careful site analysis to balance cost, construction complexity, and environmental impact for optimal performance.

Real-World Applications and Case Studies

Arch dams, known for their curved design that transfers water pressure to the canyon walls, are ideal for narrow, rocky gorges such as the Hoover Dam in the USA and the Grande Dixence Dam in Switzerland. Buttress dams feature a flat upstream face supported by buttresses on the downstream side, making them suitable for wider valleys with less stable foundations, exemplified by the Daniel-Johnson Dam in Canada. Real-world applications show arch dams excel in high-stress environments requiring less construction material, while buttress dams offer economic efficiency in broad, low-strength terrain.

Environmental Impact and Sustainability

Arch dams require less construction material due to their curved design, resulting in a smaller ecological footprint compared to buttress dams, which need extensive concrete and reinforcement. The minimal excavation and smaller reservoir areas associated with arch dams reduce habitat disruption and biodiversity loss. Buttress dams often involve higher carbon emissions during construction, whereas arch dams promote sustainability through efficient use of resources and longer service life.

Arch dam Infographic

libterm.com

libterm.com