Gas-lubricated contact minimizes friction by introducing a thin gas film between moving surfaces, enhancing efficiency and reducing wear in precision machinery. This method is particularly beneficial in high-speed applications where traditional liquid lubricants would fail due to thermal limitations or contamination risks. Discover how gas-lubricated contacts can improve Your device's performance and longevity by exploring the detailed mechanisms and applications further in this article.

Table of Comparison

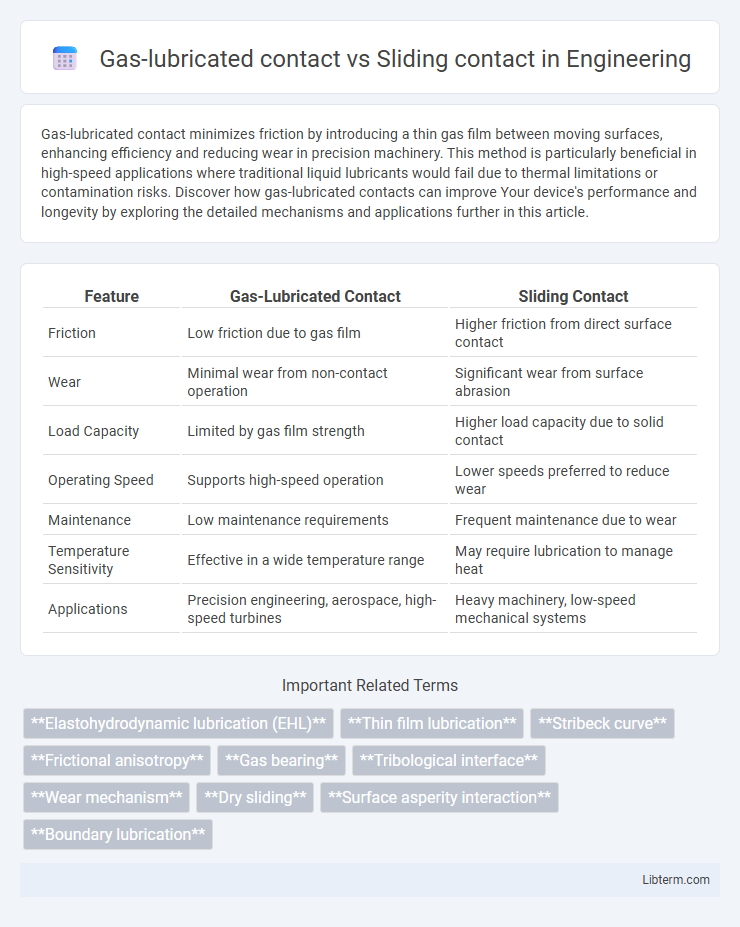

| Feature | Gas-Lubricated Contact | Sliding Contact |

|---|---|---|

| Friction | Low friction due to gas film | Higher friction from direct surface contact |

| Wear | Minimal wear from non-contact operation | Significant wear from surface abrasion |

| Load Capacity | Limited by gas film strength | Higher load capacity due to solid contact |

| Operating Speed | Supports high-speed operation | Lower speeds preferred to reduce wear |

| Maintenance | Low maintenance requirements | Frequent maintenance due to wear |

| Temperature Sensitivity | Effective in a wide temperature range | May require lubrication to manage heat |

| Applications | Precision engineering, aerospace, high-speed turbines | Heavy machinery, low-speed mechanical systems |

Introduction to Gas-Lubricated and Sliding Contacts

Gas-lubricated contacts use a thin film of gas, typically air or other inert gases, to separate interacting surfaces, significantly reducing friction and wear in precision machinery and high-speed applications. Sliding contacts involve direct surface-to-surface contact where lubrication is often provided by liquid oils or greases to minimize friction and prevent surface damage during relative motion. Gas-lubricated systems offer advantages in environments requiring low contamination and high-speed operation, whereas sliding contacts are prevalent in conventional mechanical systems needing robust load support and shock absorption.

Fundamental Principles of Gas-Lubricated Contacts

Gas-lubricated contacts operate on the principle of a thin gas film that separates surfaces, providing near-frictionless motion through hydrodynamic or aerodynamic effects. This gas film forms due to relative motion, maintaining a pressure that supports the load without direct surface contact, minimizing wear and heat generation. In contrast, sliding contacts rely on direct surface interaction with liquid or solid lubricants, resulting in higher friction and wear.

Key Characteristics of Sliding Contact Mechanisms

Sliding contact mechanisms involve direct mechanical interaction between surfaces, resulting in friction and wear that require effective lubrication to reduce damage. These mechanisms typically operate under higher load capacities but generate heat and material degradation, necessitating materials with high hardness and wear resistance. Gas-lubricated contacts minimize surface-to-surface contact by introducing a thin gas film, significantly reducing friction and wear compared to sliding contacts.

Comparative Performance Analysis: Friction and Wear

Gas-lubricated contact significantly reduces friction and wear compared to sliding contact due to the formation of a thin gas film that minimizes direct surface interaction. Sliding contact relies on boundary or mixed lubrication, leading to higher friction coefficients and increased material degradation from abrasive and adhesive wear. Experimental studies demonstrate that gas-lubricated systems achieve longer component life and lower maintenance costs, especially in high-speed, low-load applications where minimizing surface damage is critical.

Lubrication Regimes: Gas vs Traditional Lubricants

Gas-lubricated contact operates primarily within the hydrodynamic lubrication regime, where a continuous gas film separates the surfaces, significantly reducing friction and wear compared to traditional sliding contacts that rely on boundary or mixed lubrication with liquid oils. The low viscosity and high compressibility of gas enable near-frictionless movement under appropriate speed and load conditions, unlike traditional lubricants that can break down under extreme pressures or temperatures. Optimizing gas-lubricated systems involves precise control of surface geometry and operating parameters to maintain the gas film, contrasting with the chemical additives and viscosity modifiers essential in conventional sliding contact lubrication.

Material Compatibility and Surface Requirements

Gas-lubricated contact systems require materials with low surface energy and high stiffness to maintain stable gas films, often favoring ceramics or coated metals for superior wear resistance and corrosion protection. Sliding contact materials demand higher toughness and compatibility with liquid lubricants, commonly using hardened steels or alloys that can withstand direct asperity interactions and surface deformation. Optimal surface roughness in gas-lubricated contacts is extremely smooth to support thin gas films, while sliding contacts tolerate rougher surfaces to retain lubricant reservoirs and avoid metal-to-metal contact.

Application Areas: Industries and Use Cases

Gas-lubricated contact systems are extensively used in high-speed aerospace bearings and precision machine tools where minimizing friction and wear is critical. Sliding contact applications prevail in heavy machinery and automotive components, providing robust performance under high load and varying environmental conditions. Industrial sectors such as manufacturing, automotive, and energy heavily rely on gas lubrication for ultra-clean environments, while sliding contacts dominate in construction and agricultural equipment due to their durability and cost-effectiveness.

Efficiency and Operational Lifespan Comparison

Gas-lubricated contact systems exhibit higher efficiency due to reduced friction and minimal wear, enabling smoother motion and lower energy consumption compared to traditional sliding contact bearings. The operational lifespan of gas-lubricated contacts significantly exceeds that of sliding contacts, as the non-contact gas film prevents surface degradation and eliminates common wear mechanisms. Consequently, gas-lubricated contacts provide superior durability and lower maintenance costs in high-speed and precision applications.

Maintenance, Reliability, and Cost Considerations

Gas-lubricated contact systems offer superior reliability due to reduced wear and lower maintenance frequency compared to traditional sliding contact mechanisms, which suffer from higher friction and accelerated material degradation. Maintenance costs for gas-lubricated contacts are generally lower because they eliminate the need for frequent lubrication replenishment and component replacements, extending equipment lifespan. While initial investment in gas-lubricated systems may be higher, the long-term cost savings from enhanced reliability and minimized downtime provide significant economic advantages over sliding contact technologies.

Future Trends in Contact Technology and Innovations

Gas-lubricated contacts leverage thin films of pressurized gas to reduce friction and wear, offering superior durability and efficiency compared to traditional sliding contacts that rely on solid or liquid lubrication. Future trends in contact technology emphasize advancements in nano-engineered surface textures and smart sensors for real-time monitoring, enabling predictive maintenance and extended operational life. Innovations also include integrating ultra-thin gas films with adaptive control systems to optimize contact stability and energy consumption in high-precision applications like aerospace and semiconductor manufacturing.

Gas-lubricated contact Infographic

libterm.com

libterm.com