Compacted clay liners are engineered barriers used in landfills to prevent the seepage of hazardous liquids into surrounding soils and groundwater. Their low permeability and durability make them an essential component in environmental protection and waste management systems. Explore the article to understand how compacted clay liners work and their critical role in safeguarding your environment.

Table of Comparison

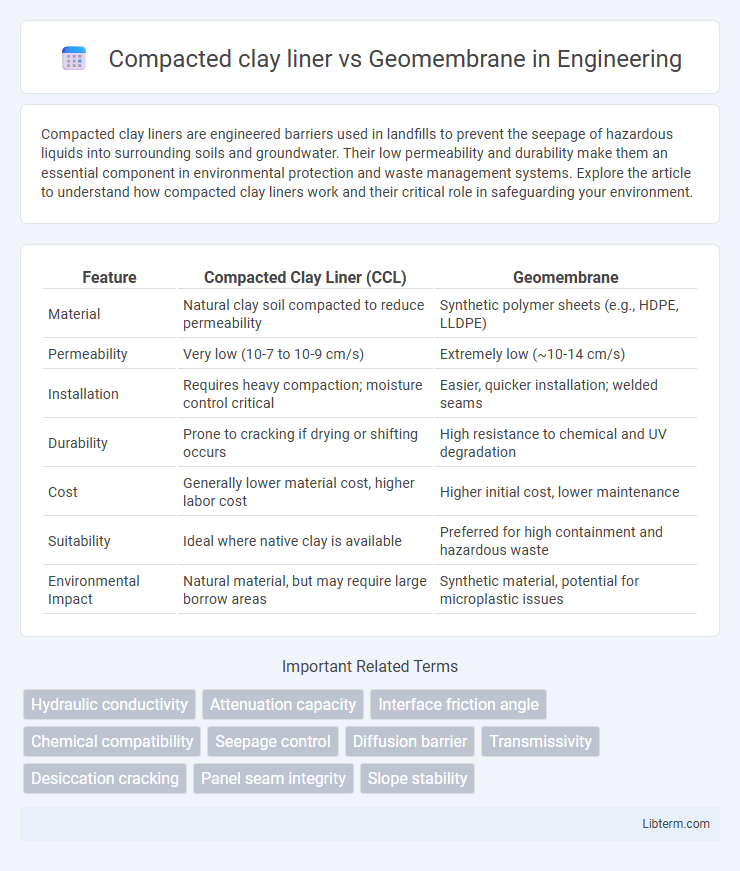

| Feature | Compacted Clay Liner (CCL) | Geomembrane |

|---|---|---|

| Material | Natural clay soil compacted to reduce permeability | Synthetic polymer sheets (e.g., HDPE, LLDPE) |

| Permeability | Very low (10-7 to 10-9 cm/s) | Extremely low (~10-14 cm/s) |

| Installation | Requires heavy compaction; moisture control critical | Easier, quicker installation; welded seams |

| Durability | Prone to cracking if drying or shifting occurs | High resistance to chemical and UV degradation |

| Cost | Generally lower material cost, higher labor cost | Higher initial cost, lower maintenance |

| Suitability | Ideal where native clay is available | Preferred for high containment and hazardous waste |

| Environmental Impact | Natural material, but may require large borrow areas | Synthetic material, potential for microplastic issues |

Introduction to Compacted Clay Liners and Geomembranes

Compacted clay liners (CCLs) are engineered barriers composed of low-permeability clay soil, designed to minimize fluid migration in landfill and waste containment applications. Geomembranes, typically made from synthetic polymers such as high-density polyethylene (HDPE), provide an impermeable barrier that effectively prevents leachate leakage and enhances environmental protection. Both CCLs and geomembranes are critical components in environmental geotechnics, with CCLs offering natural material benefits and geomembranes delivering superior impermeability and chemical resistance.

Material Composition and Properties

Compacted clay liners consist primarily of natural clay with a high swelling capacity and low permeability, making them effective barriers for preventing fluid migration in landfill liners and containment systems. Geomembranes are synthetic polymer sheets usually made from high-density polyethylene (HDPE), featuring superior tensile strength, chemical resistance, and impermeability compared to compacted clay liners. While compacted clay liners rely on soil compaction to achieve low hydraulic conductivity, geomembranes provide a uniform, durable, and flexible impermeable barrier that resists punctures and environmental degradation.

Installation Process Comparison

Compacted clay liners require meticulous moisture conditioning, layering, and mechanical compaction to achieve the desired low permeability, often demanding specialized equipment and skilled labor. Geomembrane installation involves deploying synthetic sheets that are overlapped and seamed using thermal or adhesive methods, facilitating faster placement but necessitating careful handling to avoid punctures. While compacted clay installation is weather-dependent and time-intensive, geomembranes offer quicker installation but require quality control to ensure seam integrity and long-term durability.

Permeability and Hydraulic Performance

Compacted clay liners (CCLs) exhibit permeability ranging from 10^-7 to 10^-9 cm/s, providing effective containment by minimizing fluid migration through their low hydraulic conductivity. Geomembranes, typically made from high-density polyethylene (HDPE), have near-zero permeability, often less than 10^-14 cm/s, offering superior hydraulic performance by acting as an impermeable barrier. Combining CCLs with geomembranes in composite liners enhances overall containment efficiency through reduced permeability and improved resistance to leakage in landfill and hazardous waste applications.

Durability and Chemical Resistance

Compact clay liners exhibit moderate durability, often prone to cracking under stress or desiccation, which can compromise their effectiveness over time. Geomembranes offer superior chemical resistance and maintain integrity against a wide range of contaminants, ensuring long-term containment. The selection between compacted clay liner and geomembrane depends heavily on site-specific conditions, anticipated chemical exposure, and required lifespan of the containment system.

Cost Analysis and Economic Considerations

Compacted clay liners typically present lower initial material costs but require extensive site preparation and quality control, potentially increasing labor and time expenses. Geomembranes, though higher in upfront material investment, offer faster installation, reduced land use, and enhanced durability, which can decrease long-term maintenance and remediation costs. Economic considerations must weigh the total lifecycle costs, including installation, performance efficiency, and potential environmental liabilities associated with each liner type.

Environmental Impact and Sustainability

Compacted clay liners provide a natural, low-permeability barrier that relies on native materials, minimizing synthetic waste and promoting sustainability through reuse of on-site soils. Geomembranes, though highly effective as impermeable liners, involve the production of synthetic polymers that contribute to environmental pollution and have limited recycling options. Selecting compacted clay liners can reduce carbon footprint and enhance ecological compatibility, whereas geomembranes offer long-term containment efficiency but pose challenges in waste management and material degradation.

Maintenance and Longevity

Compacted clay liners (CCLs) require regular moisture management to prevent cracking and maintain low permeability, whereas geomembranes offer superior resistance to chemical corrosion and physical damage, reducing maintenance needs. Geomembranes typically exhibit longer lifespan, often exceeding 20-30 years, while CCLs may degrade faster under fluctuating moisture and mechanical stress conditions. Maintenance for CCLs involves frequent inspection and repair of desiccation cracks, whereas geomembrane systems benefit from durable synthetic materials that ensure extended service life with minimal intervention.

Typical Applications in Environmental Engineering

Compacted clay liners (CCLs) are commonly used in landfill base liners and cover systems to minimize leachate migration due to their low permeability and natural availability. Geomembranes serve as impermeable barriers in waste containment, including hazardous waste landfills and mining applications, providing superior chemical resistance and ease of installation. Combining CCLs with geomembranes in composite liner systems enhances environmental protection by leveraging both the clay's self-sealing properties and the geomembrane's impermeability.

Choosing the Right Containment Solution

Compacted clay liners offer natural low permeability and are cost-effective for containment, but their performance hinges on proper compaction and moisture content. Geomembranes provide superior impermeability and chemical resistance, making them ideal for hazardous waste sites and applications requiring tight containment. Selecting the right solution depends on site conditions, contamination type, regulatory requirements, and long-term durability considerations.

Compacted clay liner Infographic

libterm.com

libterm.com