Digital Light Processing (DLP) technology uses a digital micromirror device to project sharp, vibrant images with high color accuracy and brightness, making it ideal for home theaters and professional presentations. Its fast response time and durability ensure consistent performance across a variety of lighting conditions. Explore the full article to understand how Digital Light Processing can enhance your visual experience.

Table of Comparison

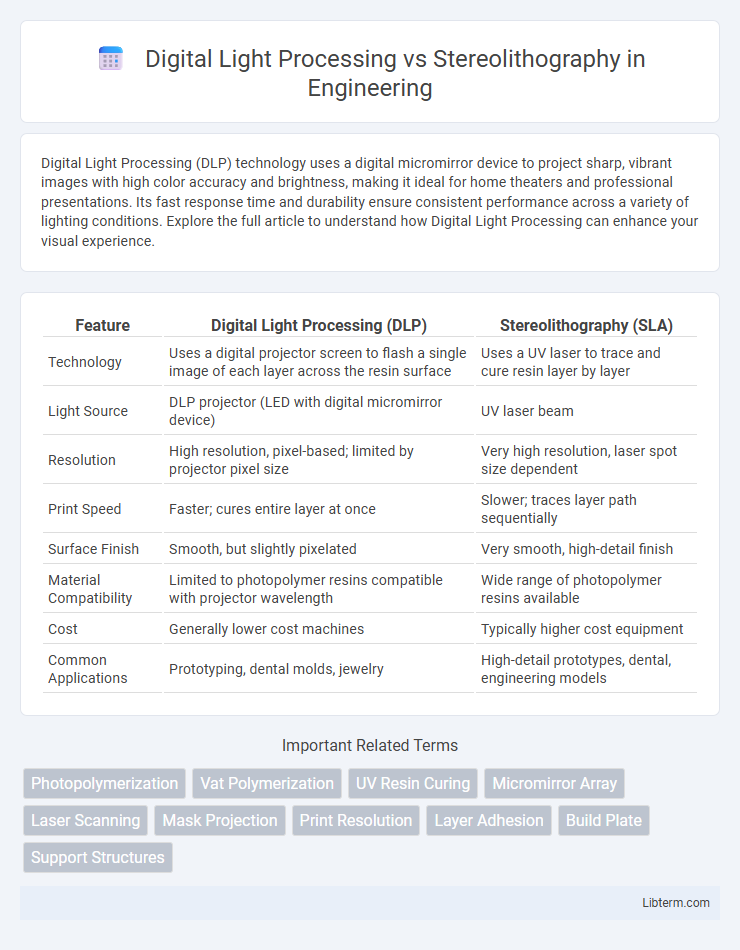

| Feature | Digital Light Processing (DLP) | Stereolithography (SLA) |

|---|---|---|

| Technology | Uses a digital projector screen to flash a single image of each layer across the resin surface | Uses a UV laser to trace and cure resin layer by layer |

| Light Source | DLP projector (LED with digital micromirror device) | UV laser beam |

| Resolution | High resolution, pixel-based; limited by projector pixel size | Very high resolution, laser spot size dependent |

| Print Speed | Faster; cures entire layer at once | Slower; traces layer path sequentially |

| Surface Finish | Smooth, but slightly pixelated | Very smooth, high-detail finish |

| Material Compatibility | Limited to photopolymer resins compatible with projector wavelength | Wide range of photopolymer resins available |

| Cost | Generally lower cost machines | Typically higher cost equipment |

| Common Applications | Prototyping, dental molds, jewelry | High-detail prototypes, dental, engineering models |

Introduction to DLP and SLA Technologies

Digital Light Processing (DLP) utilizes a digital projector screen to flash a single image of each layer all at once, enabling faster print speeds and high-resolution output. Stereolithography (SLA) employs a laser beam to trace and cure each layer point-by-point, offering exceptional detail and smooth surface finishes. Both technologies use photopolymer resin, but DLP typically excels in speed and efficiency, while SLA is recognized for precision and fine feature accuracy.

How Digital Light Processing (DLP) Works

Digital Light Processing (DLP) utilizes a digital micromirror device to project and cure entire resin layers simultaneously in rapid succession, enhancing print speed compared to layer-by-layer laser scanning in Stereolithography (SLA). The DLP projector emits UV light patterns corresponding to each layer of the 3D model, solidifying photosensitive resin with high precision and smooth surface finishes. This technology excels in producing detailed and accurate parts with shorter build times, especially for complex geometries requiring fine resolution.

Understanding Stereolithography (SLA)

Stereolithography (SLA) utilizes a UV laser to cure liquid resin layer by layer, producing highly detailed and smooth surface finishes ideal for intricate prototypes and functional parts. Unlike Digital Light Processing (DLP), which uses a digital projector to cure resin in entire layers at once, SLA offers superior resolution and feature accuracy due to its point-by-point laser curing process. SLA's precise control over the laser path enables complex geometries and fine details, making it a preferred choice for applications requiring exceptional dimensional fidelity.

Material Compatibility and Resin Choices

Digital Light Processing (DLP) printers offer a broader range of material compatibility, including flexible, castable, and tough resins, due to their rapid curing process and precise light control. Stereolithography (SLA) excels in printing high-detail models with standard photopolymer resins but typically has more limited options for specialty materials. Resin choices in DLP are favored for diverse applications such as dental, jewelry, and engineering prototypes, whereas SLA resins prioritize smooth surface finishes and accuracy for visual prototypes and functional parts.

Print Quality and Surface Finish Comparison

Digital Light Processing (DLP) offers faster print speeds with high-resolution outputs due to its pixel-based exposure, resulting in sharp details and smooth surfaces ideal for intricate designs. Stereolithography (SLA) provides superior layer uniformity and finer surface finishes through laser beam curing, producing exceptionally smooth parts with minimal post-processing. While both technologies excel in print quality, SLA generally achieves higher precision and glossy finishes, whereas DLP balances speed with quality suitable for detailed prototypes.

Speed and Efficiency: DLP vs SLA

Digital Light Processing (DLP) offers faster print speeds than Stereolithography (SLA) by curing entire layers at once using a digital projector, significantly reducing build times for complex models. SLA employs a laser to trace and cure resin point-by-point, which can result in longer print durations for highly detailed or larger parts. DLP's layer-by-layer exposure enhances efficiency in batch production while SLA provides higher precision for intricate geometries with potentially slower output.

Accuracy and Precision Differences

Digital Light Processing (DLP) offers higher precision in 3D printing by projecting entire layers of light simultaneously, resulting in smooth surface finishes and fine details. Stereolithography (SLA) achieves superior accuracy through a laser that traces each layer point-by-point, allowing for intricate geometries and sharp features. While DLP excels in speed and consistent layer curing, SLA provides enhanced dimensional accuracy, making it ideal for complex prototypes requiring tight tolerances.

Cost Analysis: Initial Investment and Maintenance

Digital Light Processing (DLP) typically requires lower initial investment compared to Stereolithography (SLA) due to its simpler hardware design and fewer moving parts. Maintenance costs for DLP are generally lower as resin handling and component replacement, such as the digital micromirror device, tend to be less expensive than SLA's laser components and mirror calibration requirements. Cost efficiency in DLP often makes it a preferred choice for small to medium-scale production, while SLA's higher precision justifies its greater upfront and upkeep expenses for industrial applications.

Common Applications in Industries

Digital Light Processing (DLP) is widely used in dental and jewelry industries due to its high precision and speed, enabling detailed molds and prosthetics. Stereolithography (SLA) is favored in automotive and aerospace sectors for producing complex prototypes and functional parts with smooth surface finishes. Both technologies support rapid prototyping and small-batch manufacturing, enhancing design validation and custom manufacturing workflows.

Choosing the Right Technology for Your Needs

Digital Light Processing (DLP) offers faster print speeds and smoother surface finishes, ideal for detailed prototypes and small-scale production. Stereolithography (SLA) provides higher resolution and finer detail accuracy, making it suitable for intricate models and complex designs. Evaluate your project's precision requirements, production volume, and budget to determine whether the rapid output of DLP or the superior detail of SLA aligns best with your needs.

Digital Light Processing Infographic

libterm.com

libterm.com