The outside circle is the area outside a circle's boundary, defined as all points whose distance from the center exceeds the circle's radius. Understanding the outside circle is important in geometry, spatial analysis, and various real-world applications like construction or design. Discover how mastering this concept can enhance Your problem-solving skills by reading the rest of the article.

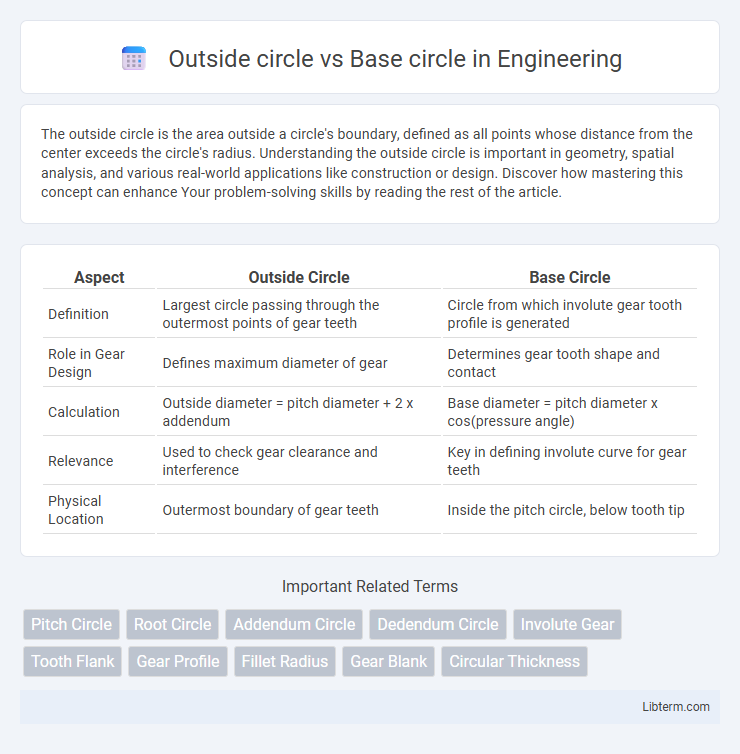

Table of Comparison

| Aspect | Outside Circle | Base Circle |

|---|---|---|

| Definition | Largest circle passing through the outermost points of gear teeth | Circle from which involute gear tooth profile is generated |

| Role in Gear Design | Defines maximum diameter of gear | Determines gear tooth shape and contact |

| Calculation | Outside diameter = pitch diameter + 2 x addendum | Base diameter = pitch diameter x cos(pressure angle) |

| Relevance | Used to check gear clearance and interference | Key in defining involute curve for gear teeth |

| Physical Location | Outermost boundary of gear teeth | Inside the pitch circle, below tooth tip |

Understanding the Basics: Outside Circle vs Base Circle

The outside circle, also known as the addendum circle, represents the largest diameter of a gear, defining the outermost boundary of the teeth. The base circle serves as the foundational diameter from which the involute tooth profile is generated, critical for accurate gear meshing and smooth power transmission. Understanding the relationship between the outside circle and base circle ensures proper gear design and performance optimization.

Key Differences Between Outside Circle and Base Circle

The outside circle is the largest circle that touches the gear teeth tips, while the base circle is the foundational circle from which the involute profile of the gear teeth is generated. The key difference lies in their roles-- the outside circle defines the gear's maximum diameter, whereas the base circle determines the shape and functionality of the gear teeth. Understanding these distinctions is crucial for accurate gear design and efficient power transmission.

The Importance of Circle Terminology in Engineering

Understanding the distinction between the outside circle and the base circle is crucial in engineering design, particularly in gear manufacturing, where precise terminology ensures accurate communication and component functionality. The outside circle defines the outermost boundary of a gear, dictating its maximum diameter and affecting spatial fit within assemblies. The base circle underpins the gear's tooth profile generation, serving as a fundamental reference for involute gear geometry and critical for ensuring proper meshing and power transmission.

Applications of Outside Circle in Mechanical Design

The outside circle, also known as the addendum circle, defines the outer boundary of a gear tooth and is critical in ensuring proper meshing and load distribution in gear systems. It provides the maximum diameter of the gear, influencing the gear's overall size and torque transmission capabilities, making it essential for high-torque applications. In mechanical design, the outside circle is used to calculate clearances, avoid interference with adjacent components, and optimize gear strength and efficiency in transmissions and precision machinery.

Role of Base Circle in Gear Manufacturing

The base circle serves as the fundamental reference in gear manufacturing, defining the involute profile that ensures smooth meshing and constant velocity ratio between gears. Unlike the outside circle, which marks the gear's maximum diameter, the base circle controls the geometry of tooth profiles through involute generation, critical for accurate power transmission and reduced wear. Precise determination of the base circle diameter directly influences gear performance, durability, and noise reduction in mechanical systems.

Calculating Dimensions: Outside Circle vs Base Circle

Calculating dimensions between the outside circle and base circle involves understanding their roles in gear geometry; the outside circle represents the maximum diameter including the teeth tips, while the base circle is the foundational diameter from which involute teeth profiles are generated. The outside circle diameter is calculated by adding twice the addendum to the pitch circle diameter, whereas the base circle diameter is derived by multiplying the pitch circle diameter by the cosine of the pressure angle. Accurate dimension calculations of these circles are crucial for gear design, ensuring proper meshing and performance in mechanical systems.

Impact on Performance: Why Circle Types Matter

The outside circle, often larger than the base circle, directly influences gear engagement and smoothness, impacting mechanical efficiency and noise levels. A precisely matched base circle ensures accurate involute tooth profiles, critical for consistent power transmission and reduced wear. Differences between outside and base circle sizes affect gear backlash and load distribution, ultimately determining system performance and longevity.

Common Mistakes in Identifying Gear Circles

Confusing the outside circle with the base circle is a frequent error in gear analysis due to their close proximity and similar appearance on technical drawings. Many engineers mistakenly measure from the gear's outermost point, the outside circle, instead of the base circle, which is critical for accurate involute gear profile generation. Proper identification relies on understanding that the base circle defines the tooth's involute curve, while the outside circle marks the gear's maximum diameter, impacting meshing and performance calculations.

Visualizing Circles: Diagrams and Examples

Visualizing circles in gear design involves comparing the outside circle, representing the gear's maximum diameter, with the base circle, which serves as the foundational circle for the involute tooth profile. Diagrams often illustrate the outside circle as the outermost boundary, while the base circle lies inside, defining the shape and motion of the gear teeth. Examples highlight the role of the base circle in generating the involute curve, critical for smooth gear meshing, contrasted with the outside circle marking the gear's physical size limits.

Best Practices for Selecting the Right Circle Type

Choosing between the outside circle and base circle in gear design hinges on the specific application requirements such as load capacity and contact stress. The outside circle defines the maximum outer diameter of the gear teeth, crucial for clearance and assembly space considerations, while the base circle serves as the starting point for involute tooth profiles, affecting the gear's kinematic behavior and efficiency. Best practices recommend selecting the outside circle to ensure physical fit within the mechanism, and optimizing the base circle radius to achieve desired pressure angles and smooth power transmission.

Outside circle Infographic

libterm.com

libterm.com