Tension shapes how your body responds to stress, often manifesting as muscle tightness or emotional strain that impacts daily performance. Recognizing and managing tension can lead to improved mental clarity and physical well-being. Explore this article to discover effective strategies for reducing tension and enhancing your overall health.

Table of Comparison

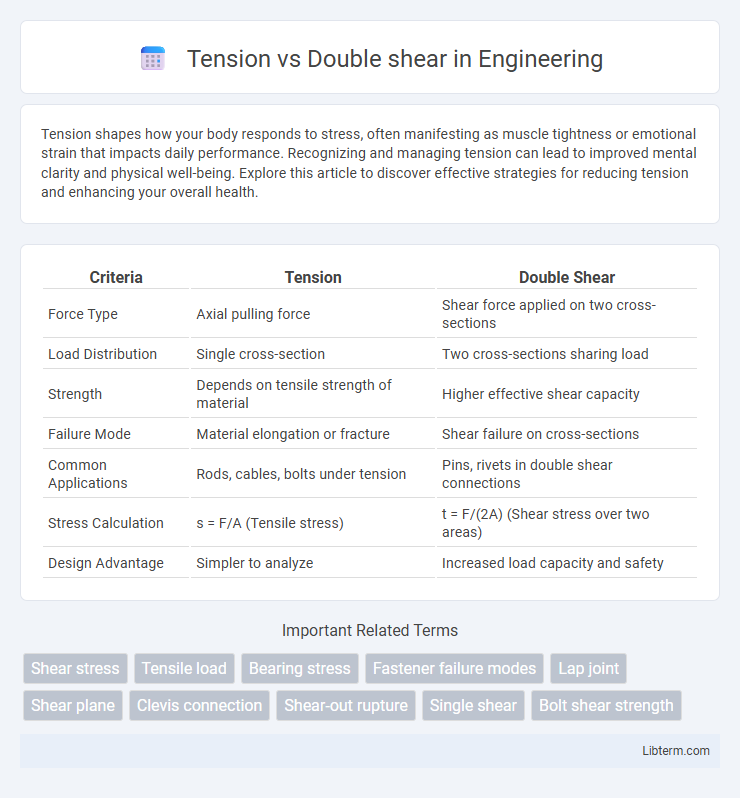

| Criteria | Tension | Double Shear |

|---|---|---|

| Force Type | Axial pulling force | Shear force applied on two cross-sections |

| Load Distribution | Single cross-section | Two cross-sections sharing load |

| Strength | Depends on tensile strength of material | Higher effective shear capacity |

| Failure Mode | Material elongation or fracture | Shear failure on cross-sections |

| Common Applications | Rods, cables, bolts under tension | Pins, rivets in double shear connections |

| Stress Calculation | s = F/A (Tensile stress) | t = F/(2A) (Shear stress over two areas) |

| Design Advantage | Simpler to analyze | Increased load capacity and safety |

Understanding Tension and Double Shear

Tension refers to the axial force that attempts to elongate a material, causing stress along its length, whereas double shear involves a force applied in two opposite directions on a material, resulting in two shear planes that share the load. Understanding tension is crucial for evaluating tensile strength and elongation limits, while analyzing double shear is key for determining the maximum load a fastener or joint can withstand before failure. Both concepts are essential in structural engineering for ensuring the integrity and safety of mechanical components under different loading conditions.

Fundamental Differences Between Tension and Double Shear

Tension involves forces acting axially to elongate a material, while double shear occurs when a material is subjected to two shear forces opposite in direction, causing it to fail along two planes. The fundamental difference lies in the mode of stress: tension induces normal stress perpendicular to the cross-section, whereas double shear generates shear stress parallel to the cross-section. Understanding these distinctions is critical for designing components subjected to axial loads versus those exposed to multi-plane shear forces.

Mechanical Principles of Tension Loads

Tension loads generate axial forces that elongate materials by pulling apart along their length, relying on the material's tensile strength to resist failure. Double shear involves a component being simultaneously cut along two planes, effectively doubling the shear area and increasing load capacity compared to single shear conditions. Understanding the mechanical principles of tension versus double shear is critical in designing fasteners and structural elements for optimal stress distribution and safety.

Mechanics of Double Shear Forces

Double shear occurs when a force is distributed across two shear planes, effectively doubling the resisting area compared to single shear, which enhances structural capacity. The mechanics of double shear involve dividing the applied load into two equal shear forces, reducing the stress experienced by each shear plane and increasing the connection's strength. This principle is critical in mechanical joints like bolted or riveted connections, where double shear improves the overall stability and durability under tensile loads.

Typical Applications in Engineering Structures

Tension members in engineering structures are primarily used in bridges, trusses, and cranes where axial loads pull components apart, requiring high tensile strength materials like steel rods or cables. Double shear connections commonly occur in bolted or riveted joints within steel frameworks, such as building frames and mechanical linkages, providing enhanced load distribution and reduced stress concentration by transferring forces through two shear planes. Both tension and double shear mechanisms are critical in ensuring structural integrity, with tension ideal for pure axial loads and double shear preferred in joint designs to prevent single shear failure.

Advantages and Disadvantages of Tension vs Double Shear

Tension connections provide straightforward load transfer with uniform stress distribution, making them easier to design and inspect, but they are limited in carrying high loads compared to double shear connections. Double shear connections offer increased strength by distributing forces over two shear planes, reducing stress concentration and enhancing load capacity, although they require more complex fabrication and higher costs. While tension joints are preferred for simplicity and cost-efficiency in low to moderate load conditions, double shear joints excel in applications demanding superior strength and durability.

Material Selection for Tension and Double Shear Loads

Selecting materials for tension and double shear loads requires careful consideration of mechanical properties such as tensile strength, ductility, and toughness. Materials like high-strength steel and aluminum alloys are ideal for tension applications due to their excellent elongation and resistance to fracture, while for double shear loading, materials with superior shear strength and fatigue resistance such as stainless steel and titanium alloys are preferred. Optimizing material choice enhances structural integrity and performance by addressing the specific stress distributions and failure modes inherent in tension and double shear conditions.

Failure Modes in Tension and Double Shear Connections

Failure modes in tension connections primarily involve yielding or fracture of the tension member, bolt pullout, or net section rupture due to stress concentration. Double shear connections exhibit failure by bolt shear or bearing failure on connected elements, as the applied load is distributed over two shear planes, reducing stress on individual fasteners. Understanding these failure mechanisms is essential for designing safe and efficient structural connections that optimize material strength and load distribution.

Design Considerations for Structural Safety

Design considerations for structural safety require understanding the differences between tension and double shear conditions. Tension involves axial forces pulling components apart, demanding materials with high tensile strength and effective load distribution to prevent failure. Double shear conditions divide forces across two planes, enhancing structural capacity by reducing stress concentration, which is critical in designing connections such as bolts or rivets to ensure durability and safety.

Industry Standards and Testing Methods

Tension and double shear are critical mechanical stresses assessed in structural and materials engineering to ensure component reliability and safety according to industry standards such as ASTM E8 for tension testing and ASTM E399 for shear testing. Testing methods involve uniaxial tensile tests for tension strength measurement and double shear tests performed on specialized fixtures to evaluate joint or fastener integrity under shear loads. Adherence to these standards ensures reproducible results and compliance with engineering design requirements across aerospace, automotive, and construction industries.

Tension Infographic

libterm.com

libterm.com