Hardening strengthens your system's security by reducing vulnerabilities and limiting potential attack surfaces. Implementing best practices such as patch management, configuration adjustments, and disabling unnecessary services enhances protection against cyber threats. Explore the rest of the article to learn effective hardening techniques for safeguarding your digital environment.

Table of Comparison

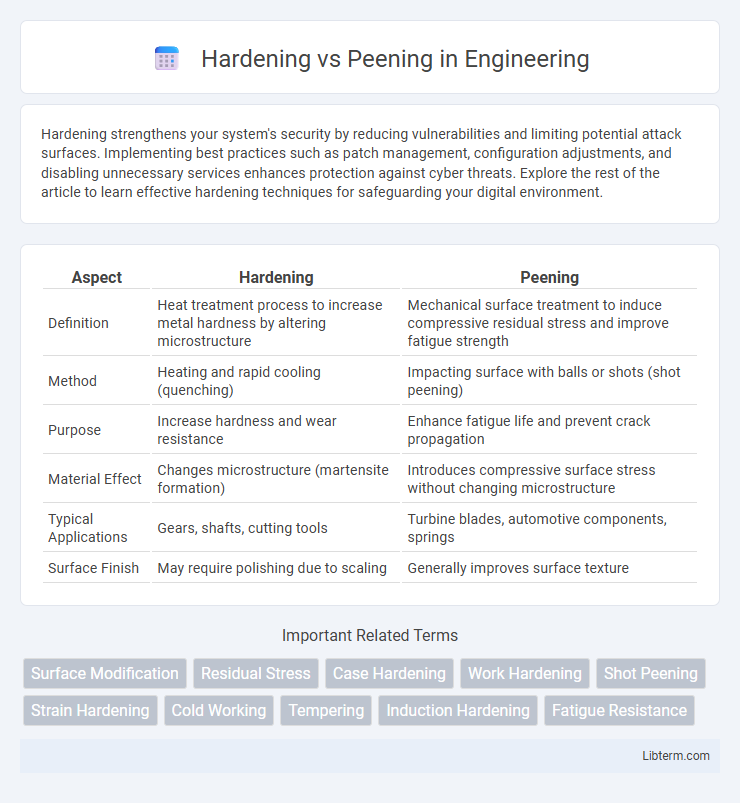

| Aspect | Hardening | Peening |

|---|---|---|

| Definition | Heat treatment process to increase metal hardness by altering microstructure | Mechanical surface treatment to induce compressive residual stress and improve fatigue strength |

| Method | Heating and rapid cooling (quenching) | Impacting surface with balls or shots (shot peening) |

| Purpose | Increase hardness and wear resistance | Enhance fatigue life and prevent crack propagation |

| Material Effect | Changes microstructure (martensite formation) | Introduces compressive surface stress without changing microstructure |

| Typical Applications | Gears, shafts, cutting tools | Turbine blades, automotive components, springs |

| Surface Finish | May require polishing due to scaling | Generally improves surface texture |

Introduction to Hardening and Peening

Hardening and peening are metallurgical processes that enhance the mechanical properties of metals, primarily steel. Hardening involves heating the metal to a high temperature followed by rapid cooling, typically quenching, to increase surface hardness and wear resistance. Peening, commonly shot peening, uses impact forces to induce compressive residual stress on the metal surface, improving fatigue strength and preventing crack propagation.

Understanding Hardening: Definition and Process

Hardening is a heat treatment process that increases the hardness and strength of metals, primarily steel, by altering their microstructure through controlled heating and rapid cooling. This process typically involves heating the metal to a high temperature where its crystal structure changes, followed by quenching in water, oil, or air to lock the new structure in place. The result is enhanced wear resistance and durability, making hardened metals ideal for tools, machinery components, and automotive parts.

Peening Explained: Techniques and Applications

Peening is a mechanical surface treatment that enhances metal properties by inducing compressive stresses through repeated impacts, improving fatigue resistance and durability. Common techniques include shot peening, where small spherical media bombard the surface, and laser peening, which uses high-energy laser pulses for deeper stress penetration. Applications of peening span aerospace, automotive, and manufacturing industries, targeting components like turbine blades, gears, and springs to prevent crack initiation and extend service life.

Key Differences: Hardening vs Peening

Hardening involves increasing a metal's hardness and strength by heat treatment processes such as quenching and tempering, which alter the metal's microstructure. Peening is a surface treatment technique that enhances fatigue resistance and relieves residual stresses through mechanical deformation, typically using shot or laser peening. Key differences include hardening targeting bulk material properties while peening primarily improves surface characteristics without significant changes to the overall microstructure.

Benefits of Hardening in Material Engineering

Hardening significantly improves the wear resistance and mechanical strength of metals by increasing surface hardness through processes like quenching and tempering. This enhancement extends the lifespan of components subjected to friction and high stress, reducing maintenance costs in industrial applications. Material engineers prioritize hardening to achieve greater durability and fatigue resistance in critical parts such as gears, shafts, and cutting tools.

Advantages of Peening for Surface Enhancement

Peening offers superior surface enhancement by inducing beneficial compressive residual stresses, which significantly improve fatigue strength and resistance to stress corrosion cracking. Unlike conventional hardening methods, peening refines surface microstructure without altering bulk material properties, preserving overall toughness. Its capability to enhance durability and extend component life in critical applications makes peening a preferred technique in aerospace, automotive, and heavy machinery industries.

Common Applications: Where Hardening and Peening Are Used

Hardening is commonly applied in manufacturing gears, cutting tools, and automotive components to enhance wear resistance and increase surface strength. Peening is frequently used in aerospace structures, bridges, and pressure vessels to improve fatigue life by inducing beneficial compressive stresses. Both processes are essential in extending the service life of metal parts subjected to high stress and cyclic loading conditions.

Factors Influencing Process Selection

Hardening and peening are selected based on factors such as material type, desired surface properties, and application requirements. Hardening is preferred for increasing wear resistance and strength in steel alloys through heat treatment, while peening is chosen to improve fatigue life by inducing compressive residual stresses on the surface. Considerations including component geometry, cost efficiency, and thermal sensitivity play critical roles in determining the optimal process.

Impact on Material Properties and Performance

Hardening increases a material's hardness and wear resistance by altering its internal microstructure, typically through heat treatment, resulting in improved strength but often reduced ductility. Peening enhances fatigue resistance and stress corrosion cracking by inducing compressive residual stresses on the surface without significantly changing the material's core properties. Combining hardening and peening optimizes both surface durability and overall mechanical performance in critical applications.

Conclusion: Choosing the Right Process for Your Needs

Selecting between hardening and peening depends on the specific mechanical requirements and surface properties desired. Hardening enhances wear resistance and strength by altering the metal's microstructure, while peening improves fatigue life and surface compressive stresses without significant hardness changes. Evaluating factors such as load conditions, material type, and long-term performance will guide the optimal choice for manufacturing or repair applications.

Hardening Infographic

libterm.com

libterm.com