Elongation is the process of lengthening or stretching an object, often seen in biological growth or materials science. In biology, it refers to the extension of cells or tissues, crucial for development and repair. Explore the full article to understand how elongation impacts various fields and your daily life.

Table of Comparison

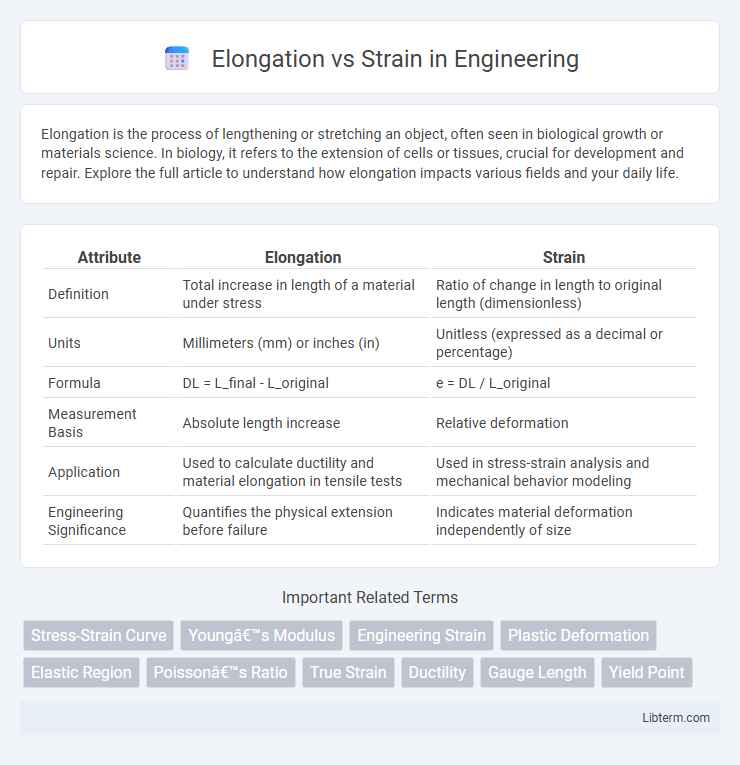

| Attribute | Elongation | Strain |

|---|---|---|

| Definition | Total increase in length of a material under stress | Ratio of change in length to original length (dimensionless) |

| Units | Millimeters (mm) or inches (in) | Unitless (expressed as a decimal or percentage) |

| Formula | DL = L_final - L_original | e = DL / L_original |

| Measurement Basis | Absolute length increase | Relative deformation |

| Application | Used to calculate ductility and material elongation in tensile tests | Used in stress-strain analysis and mechanical behavior modeling |

| Engineering Significance | Quantifies the physical extension before failure | Indicates material deformation independently of size |

Understanding Elongation: A Fundamental Overview

Elongation measures the increase in length of a material under tensile stress, expressed as a percentage of its original length. Strain quantifies deformation as the ratio of change in length to the initial length, making it a dimensionless measure of material stretch. Understanding elongation is crucial for evaluating material flexibility and ductility in engineering and material science applications.

Defining Strain in Material Science

Strain in material science quantifies the deformation of a material relative to its original length, expressed as a dimensionless ratio or percentage. Unlike elongation, which measures absolute length increase, strain captures the proportional change, enabling standardized comparisons across different materials and sizes. This fundamental metric helps engineers assess material behavior under stress, crucial for designing structures that withstand mechanical forces.

Elongation vs Strain: Key Differences

Elongation measures the total increase in length of a material under tensile stress, expressed as a percentage of the original length, while strain quantifies the deformation as a dimensionless ratio of change in length to the original length. Elongation is a macroscopic, easily observed property often used in material testing for ductility, whereas strain is a fundamental mechanical parameter critical in stress-strain analysis and finite element modeling. Strain provides a precise description of deformation behavior at the microscopic or engineering scale, differing from elongation's straightforward measurement of elongation magnitude.

Mathematical Representation of Elongation

Elongation is mathematically represented as the change in length (DL) of a material divided by its original length (L0), expressed as e = DL / L0. This dimensionless quantity describes the deformation relative to the initial length, providing a standardized measure of strain. Strain, therefore, quantifies elongation by capturing the fractional increase in length under tensile stress conditions.

Measuring Strain: Methods and Units

Measuring strain involves calculating the deformation of a material relative to its original length, typically expressed as a dimensionless ratio or percentage. Common methods include using strain gauges, extensometers, and digital image correlation, which provide precise measurements of elongation per unit length. Units of strain are often reported in microstrain (ue) for small deformations or as a decimal fraction (e.g., mm/mm) in engineering applications.

Factors Affecting Elongation and Strain

Elongation and strain are both measures of deformation in materials under stress, with elongation representing the absolute change in length and strain indicating the relative change. Factors affecting elongation include material composition, temperature, and applied load, where ductile materials and higher temperatures typically increase elongation. Strain is influenced by the material's elastic modulus, cross-sectional area, and the magnitude of the applied force, with higher forces and lower stiffness resulting in greater strain.

Practical Applications of Elongation and Strain

Elongation measures the percentage increase in length of a material under tensile stress, providing critical data for assessing ductility in metal forming and structural engineering. Strain quantifies deformation as a ratio of change in dimension to original dimensions, essential for analyzing stress distribution in civil infrastructure and mechanical components. Both metrics guide material selection and safety evaluations in aerospace, automotive manufacturing, and construction industries.

Stress-Strain Curve: Interpreting Results

Elongation measures the total deformation of a material under tensile stress, expressed as a percentage of its original length, while strain represents the dimensionless ratio of change in length to original length. In the stress-strain curve, elongation corresponds to the material's ductility, identified by the curve's extension before fracture, whereas strain highlights the elastic and plastic deformation phases. Interpreting these results allows engineers to determine mechanical properties such as yield strength, ultimate tensile strength, and fracture point, essential for material selection and structural analysis.

Importance in Engineering and Material Testing

Elongation measures the absolute change in length of a material under tensile stress, providing critical data on ductility and failure points, while strain quantifies the relative deformation as a dimensionless ratio, essential for assessing material behavior and structural integrity. Both metrics are indispensable in engineering design and material testing for predicting performance, ensuring safety, and optimizing material selection in construction, aerospace, and manufacturing industries. Accurate evaluation of elongation and strain enables engineers to develop materials that withstand operational stresses and comply with industry standards such as ASTM and ISO.

Summary: Choosing the Right Parameter for Analysis

Elongation measures the absolute increase in length of a material under stress, while strain represents the relative deformation as a dimensionless ratio or percentage. Strain is generally preferred for analysis because it normalizes deformation across different specimen sizes, enabling more accurate comparisons and material behavior predictions. Selecting strain over elongation ensures consistent characterization in mechanical testing and structural analysis.

Elongation Infographic

libterm.com

libterm.com