Spiral heat exchangers maximize heat transfer efficiency through their compact, coiled design, allowing effective handling of fluids with high fouling tendencies and high-viscosity liquids. Their self-cleaning flow path reduces maintenance needs while maintaining optimal performance across various industries. Explore the rest of the article to understand how this advanced technology can enhance your thermal management solutions.

Table of Comparison

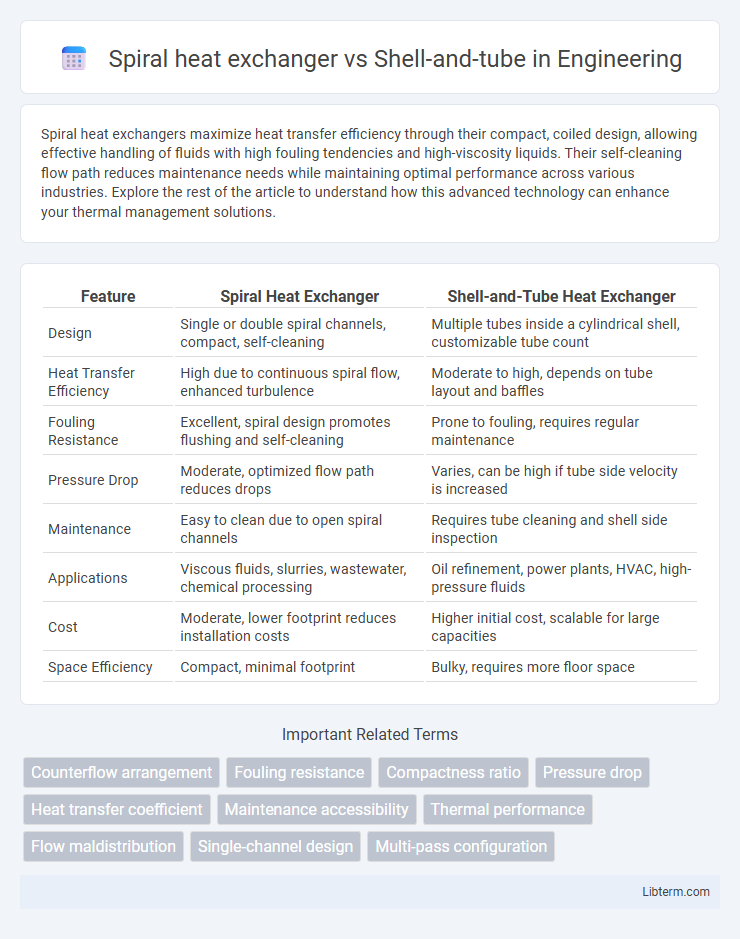

| Feature | Spiral Heat Exchanger | Shell-and-Tube Heat Exchanger |

|---|---|---|

| Design | Single or double spiral channels, compact, self-cleaning | Multiple tubes inside a cylindrical shell, customizable tube count |

| Heat Transfer Efficiency | High due to continuous spiral flow, enhanced turbulence | Moderate to high, depends on tube layout and baffles |

| Fouling Resistance | Excellent, spiral design promotes flushing and self-cleaning | Prone to fouling, requires regular maintenance |

| Pressure Drop | Moderate, optimized flow path reduces drops | Varies, can be high if tube side velocity is increased |

| Maintenance | Easy to clean due to open spiral channels | Requires tube cleaning and shell side inspection |

| Applications | Viscous fluids, slurries, wastewater, chemical processing | Oil refinement, power plants, HVAC, high-pressure fluids |

| Cost | Moderate, lower footprint reduces installation costs | Higher initial cost, scalable for large capacities |

| Space Efficiency | Compact, minimal footprint | Bulky, requires more floor space |

Introduction to Spiral Heat Exchangers

Spiral heat exchangers feature a unique design where two flat metal plates are coiled to form spiral channels, facilitating efficient heat transfer in compact spaces. This configuration provides enhanced turbulence and self-cleaning properties, making them ideal for handling viscous fluids or fluids with suspended solids. Compared to traditional shell-and-tube heat exchangers, spiral heat exchangers offer lower fouling rates and easier maintenance, improving operational efficiency in industries like chemical processing and wastewater treatment.

Overview of Shell-and-Tube Heat Exchangers

Shell-and-tube heat exchangers consist of a series of tubes enclosed within a cylindrical shell, facilitating efficient heat transfer between fluids through tube and shell sides. They are widely used in industries due to their robust design, ability to handle high pressure and temperature, and ease of maintenance. Their modular construction allows customization for various flow rates and thermal loads, making them versatile for chemical processing, power generation, and oil refining.

Design Differences and Construction

Spiral heat exchangers feature two flat metal strips wound in a spiral, creating a compact, self-cleaning channel ideal for handling fouling fluids, while shell-and-tube heat exchangers consist of a bundle of tubes housed within a cylindrical shell, allowing for high pressure and temperature operations. Spiral designs exhibit a single, continuous channel promoting uniform fluid velocity and enhanced heat transfer, whereas shell-and-tube units rely on baffles to direct flow and increase turbulence. Construction-wise, spiral heat exchangers are made from corrosion-resistant alloys formed into spiral plates, offering space-saving benefits, whereas shell-and-tube exchangers utilize welded tube sheets and removable tube bundles, facilitating maintenance and repair.

Heat Transfer Efficiency Comparison

Spiral heat exchangers exhibit superior heat transfer efficiency compared to shell-and-tube designs due to their compact geometry and high turbulence levels within the spiral channels, which enhance convective heat transfer coefficients. The continuous spiral flow path minimizes dead zones and fouling, maintaining consistent thermal performance over time and reducing maintenance costs. Shell-and-tube heat exchangers typically have lower efficiency because of flow distribution challenges and lower turbulence in shell-side fluids, which can cause thermal gradients and reduced heat transfer rates.

Space Requirements and Footprint

Spiral heat exchangers feature a compact design with a smaller footprint, making them ideal for installations with limited space. Their continuous channel design allows for efficient heat transfer within a reduced spatial envelope compared to shell-and-tube exchangers, which typically require larger volumes due to their multi-pass shell and tube bundles. The reduced space requirements of spiral heat exchangers enhance flexibility in plant layout and reduce installation costs in constrained environments.

Maintenance and Cleaning Considerations

Spiral heat exchangers offer easier maintenance and cleaning due to their self-cleaning design and accessible spiral channels, minimizing fouling and reducing downtime. Shell-and-tube heat exchangers require regular mechanical cleaning and chemical treatments because of their multiple tubes and baffle configurations, which can trap debris and deposits. The simpler geometry of spiral heat exchangers results in lower maintenance costs and more efficient cleaning processes compared to the complex maintenance requirements of shell-and-tube units.

Pressure Drop and Flow Characteristics

Spiral heat exchangers exhibit lower pressure drop compared to shell-and-tube designs due to their continuous flow path and compact spiral geometry, which reduces turbulence and flow resistance. The spiral configuration promotes uniform velocity distribution and efficient heat transfer with minimal fouling, enhancing flow characteristics under varying operational conditions. In contrast, shell-and-tube exchangers often experience higher pressure drops caused by baffles and multi-pass arrangements, which can induce flow maldistribution and increased maintenance requirements.

Cost Analysis: Installation and Operation

Spiral heat exchangers generally offer lower installation costs due to their compact design and fewer components, reducing material and labor expenses compared to shell-and-tube exchangers. Operational costs for spiral heat exchangers are typically lower because their self-cleaning spiral channels minimize fouling, leading to less frequent maintenance and downtime. Shell-and-tube exchangers, while versatile, often incur higher costs from complex assembly and more intensive cleaning requirements, impacting long-term operational budgets.

Typical Applications and Industry Uses

Spiral heat exchangers excel in handling viscous fluids and slurries, making them ideal for wastewater treatment, chemical processing, and food industries where fouling and clogging are common issues. Shell-and-tube heat exchangers are widely used in power plants, oil refineries, and HVAC systems due to their robustness and ability to operate under high pressure and temperature conditions. Industries demanding heat exchange for high-pressure steam, petrochemical processing, and large-scale cooling typically prefer shell-and-tube models for their reliability and scalability.

Selecting the Right Heat Exchanger for Your Needs

Spiral heat exchangers offer superior fouling resistance and compact design, making them ideal for handling viscous fluids and applications with limited space. Shell-and-tube heat exchangers excel in high-pressure and high-temperature environments, providing easy maintenance and scalability for large industrial processes. Choosing between them depends on factors like fluid properties, thermal requirements, maintenance accessibility, and spatial constraints.

Spiral heat exchanger Infographic

libterm.com

libterm.com