Viscosity measures a fluid's resistance to flow, playing a crucial role in applications ranging from automotive lubricants to food production. High viscosity fluids, like honey, flow slowly, while low viscosity fluids, such as water, move quickly and easily. Discover how understanding viscosity can improve Your processes by exploring the full article.

Table of Comparison

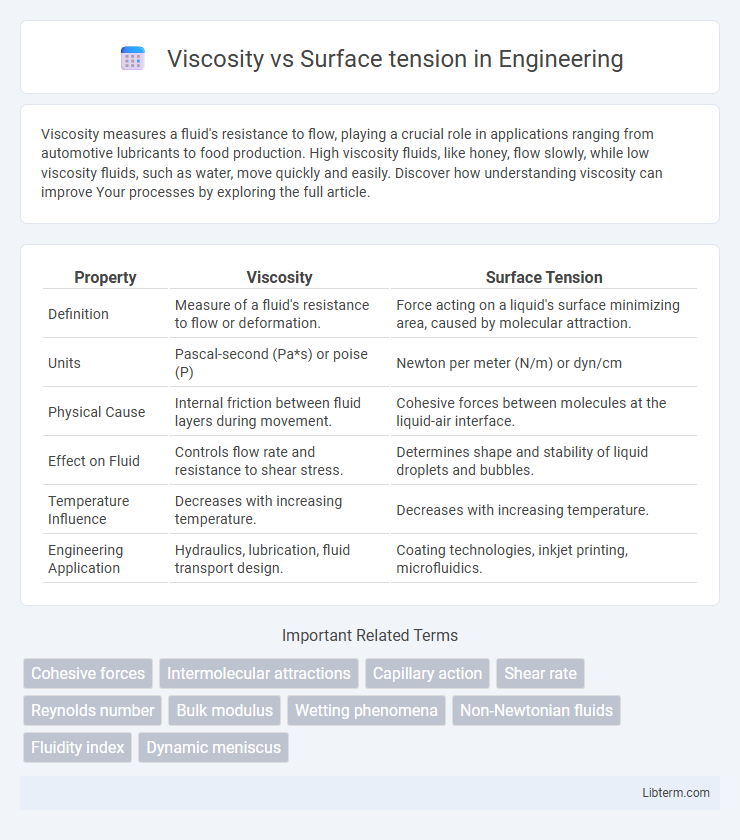

| Property | Viscosity | Surface Tension |

|---|---|---|

| Definition | Measure of a fluid's resistance to flow or deformation. | Force acting on a liquid's surface minimizing area, caused by molecular attraction. |

| Units | Pascal-second (Pa*s) or poise (P) | Newton per meter (N/m) or dyn/cm |

| Physical Cause | Internal friction between fluid layers during movement. | Cohesive forces between molecules at the liquid-air interface. |

| Effect on Fluid | Controls flow rate and resistance to shear stress. | Determines shape and stability of liquid droplets and bubbles. |

| Temperature Influence | Decreases with increasing temperature. | Decreases with increasing temperature. |

| Engineering Application | Hydraulics, lubrication, fluid transport design. | Coating technologies, inkjet printing, microfluidics. |

Introduction to Viscosity and Surface Tension

Viscosity measures a fluid's resistance to flow, quantifying the internal friction between its molecules, while surface tension describes the cohesive force at a fluid's surface causing it to behave like a stretched elastic membrane. Both properties arise from molecular interactions but affect fluids differently: viscosity influences flow behavior and energy dissipation, whereas surface tension governs droplet formation and interface stability. Understanding these parameters is crucial in fluid mechanics, material science, and various industrial processes involving liquids and gases.

Defining Viscosity: Concepts and Importance

Viscosity measures a fluid's resistance to flow, quantifying internal friction between its molecules, which directly influences its ability to deform under shear stress. This property plays a crucial role in industrial processes such as lubrication, polymer manufacturing, and fluid transport, where controlling flow behavior is essential. Understanding viscosity helps optimize equipment performance and product quality by predicting how fluids respond to varying temperature and pressure conditions.

Understanding Surface Tension: Key Principles

Surface tension arises from cohesive forces between liquid molecules at the interface, creating a minimized surface area. This phenomenon is crucial for processes like droplet formation, capillary action, and the behavior of liquids on different substrates. Understanding surface tension depends on factors such as temperature, intermolecular forces, and the presence of surfactants that alter the liquid's surface energy.

Molecular Basis of Viscosity

Viscosity arises from intermolecular forces and the resistance to the relative motion of adjacent molecular layers, depending on the strength and nature of molecular interactions such as hydrogen bonding or van der Waals forces. Molecules in viscous fluids exhibit stronger cohesive forces, leading to higher energy dissipation when layers slide past each other. This molecular friction contrasts with surface tension, which is primarily governed by intermolecular forces acting at the interface, influencing a fluid's surface shape rather than its internal flow resistance.

Molecular Basis of Surface Tension

Surface tension arises from the cohesive forces between liquid molecules, particularly the imbalance of intermolecular attractions at the liquid-air interface that creates a minimized surface area. Unlike viscosity, which measures a liquid's resistance to flow influenced by internal friction between layers, surface tension is governed by molecular interactions that cause the liquid surface to behave like an elastic membrane. The strength of surface tension depends on the type and strength of intermolecular forces such as hydrogen bonding, Van der Waals forces, and polarity within the liquid.

Fundamental Differences Between Viscosity and Surface Tension

Viscosity measures a fluid's internal resistance to flow, quantified by the force per unit area required to move one layer of fluid over another, impacting fluid dynamics in liquids and gases. Surface tension refers to the cohesive force at the liquid-air interface, caused by molecular attractions that minimize surface area and result in phenomena like droplet formation and capillary action. While viscosity governs the fluid's flow behavior, surface tension controls the fluid's external surface shape and interaction with surrounding phases.

Measuring Viscosity: Methods and Applications

Measuring viscosity involves techniques such as capillary viscometers, rotational viscometers, and oscillatory rheometers, each providing precise data on a fluid's resistance to flow under varying conditions. Capillary viscometers quantify viscosity by timing fluid flow through narrow tubes, ideal for low-viscosity liquids, while rotational viscometers measure torque required to rotate an object in the fluid, suitable for complex or non-Newtonian fluids. These measurement methods are critical in applications ranging from lubricants formulation and polymer processing to quality control in food and pharmaceutical industries, where viscosity directly influences performance and stability.

Measuring Surface Tension: Techniques and Uses

Measuring surface tension involves techniques such as the drop weight method, Wilhelmy plate method, and pendant drop method, each providing precise quantification of liquid-air interface forces. Instruments like tensiometers utilize these techniques to analyze liquids in industries like pharmaceuticals, coatings, and petrochemicals, ensuring product quality and performance. Accurate surface tension measurement supports applications in inkjet printing, emulsification, and detergent formulation, where fluid behavior critically impacts process efficiency.

Real-World Examples and Applications

Viscosity influences paint application by controlling flow and drying time, ensuring smooth, even coatings, while surface tension affects droplet formation in inkjet printing for precise image quality. In automotive engineering, low viscosity lubricants reduce friction in engines, enhancing efficiency, whereas high surface tension liquids, like water repellents, protect surfaces by minimizing wetting and corrosion. Food industry processes utilize viscosity to create desired textures in products like sauces, while surface tension plays a role in forming stable foams in beverages such as beer and coffee.

Viscosity vs Surface Tension: Summary and Conclusion

Viscosity measures a fluid's resistance to flow, influencing how it deforms under shear stress, while surface tension quantifies the cohesive forces at a fluid's surface that minimize surface area. Viscosity impacts fluid dynamics and energy dissipation in systems such as lubrication and pipeline flow, whereas surface tension governs phenomena like droplet formation, capillarity, and wetting behavior. Understanding the interplay between viscosity and surface tension is crucial in applications ranging from inkjet printing to biomedical devices, where precise control of fluid behavior is essential.

Viscosity Infographic

libterm.com

libterm.com