Bearing force refers to the load or pressure exerted on a bearing, crucial in mechanical systems for ensuring smooth rotational or linear motion. Proper understanding and management of bearing force can prevent equipment failure, extend machinery lifespan, and optimize performance. Explore the rest of the article to learn how to calculate, control, and apply bearing force effectively in your projects.

Table of Comparison

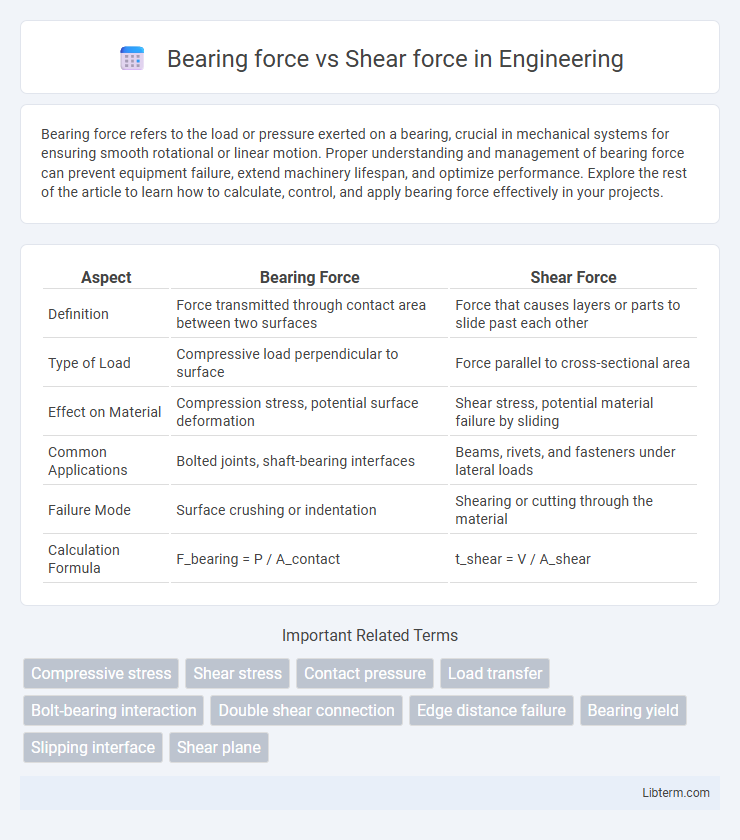

| Aspect | Bearing Force | Shear Force |

|---|---|---|

| Definition | Force transmitted through contact area between two surfaces | Force that causes layers or parts to slide past each other |

| Type of Load | Compressive load perpendicular to surface | Force parallel to cross-sectional area |

| Effect on Material | Compression stress, potential surface deformation | Shear stress, potential material failure by sliding |

| Common Applications | Bolted joints, shaft-bearing interfaces | Beams, rivets, and fasteners under lateral loads |

| Failure Mode | Surface crushing or indentation | Shearing or cutting through the material |

| Calculation Formula | F_bearing = P / A_contact | t_shear = V / A_shear |

Introduction to Bearing Force and Shear Force

Bearing force refers to the load transmitted between two contacting surfaces, typically acting perpendicular to the interface, crucial in supporting structural components and preventing material failure. Shear force acts parallel to the surface or cross-section of a material, causing layers to slide relative to each other and is essential in analyzing beam bending and structural integrity. Understanding the distinct roles of bearing and shear forces aids in designing safe and efficient mechanical and civil engineering systems.

Defining Bearing Force: Key Concepts

Bearing force refers to the load applied perpendicularly to the surface area of a structural component, causing compressive stress concentrated at the contact interface. It is critical in bolted or pinned connections where forces are transmitted through contact pressure between elements. Understanding bearing force is essential for designing components to prevent material deformation or failure due to excessive compressive stress.

Understanding Shear Force in Structures

Shear force in structures refers to the internal force that acts parallel to the cross-sectional area, causing layers to slide against each other. It is critical for analyzing beam behavior under loads, as shear force influences the design of reinforcements to prevent structural failure. Understanding shear force distribution helps engineers ensure the stability and durability of beams, columns, and other structural components.

Fundamental Differences: Bearing vs. Shear Force

Bearing force acts perpendicular to the contact surface, distributing load over an area to prevent material crushing, while shear force acts parallel to the surface, causing layers to slide past one another. Bearing stress results from compressive loads concentrated over a small area at points of contact, whereas shear stress arises from forces that attempt to cut or shear the material along a plane. Understanding these fundamental differences is essential for designing joints and connections that can withstand specific load conditions without failure.

Calculation Methods for Bearing Force

Bearing force calculation methods involve analyzing the contact pressure between two mating surfaces, typically using the formula \( F_b = P_b \times A_b \), where \( F_b \) is the bearing force, \( P_b \) is the allowable bearing pressure, and \( A_b \) is the projected bearing area. Engineers calculate bearing force by considering factors such as load distribution, material properties, and geometry to ensure structural integrity under operational loads. Accurate determination of bearing forces is critical in designing joints, fasteners, and supports to prevent failure caused by excessive pressure or deformation.

Shear Force Analysis Techniques

Shear force analysis techniques involve evaluating the internal forces that cause layers of a material to slide past each other, which is critical in structural engineering to prevent failure. Methods such as the shear diagram, finite element analysis (FEA), and strain gauge measurements help determine the magnitude and distribution of shear forces within beams and other components. Accurate shear force analysis ensures structural integrity by guiding the design of reinforcements and selecting appropriate materials to withstand applied loads.

Applications of Bearing and Shear Forces in Engineering

Bearing force plays a critical role in supporting loads transmitted through shafts, pins, and bolts, ensuring structural stability in mechanical joints and machinery. Shear force is essential in analyzing the ability of beams, rivets, and fasteners to resist sliding failure along a plane, preventing structural deformation or collapse. Engineers use bearing forces to design contact surfaces under compressive stress and shear forces to evaluate the integrity of components subjected to lateral loads in bridges, buildings, and automotive systems.

Common Failure Modes: Bearing vs. Shear Failure

Bearing failure occurs when the contact stress between a bolt and the hole edge exceeds the material's compressive strength, causing deformation or elongation of the hole. Shear failure happens when the applied shear force exceeds the material's shear strength, resulting in the bolt or connected plate fracturing along the shear plane. Common failure modes differentiate by bearing failure showing localized crushing or elongation near fastener holes, while shear failure presents as a clean fracture across the bolt or member.

Design Considerations for Bearing and Shear Forces

Design considerations for bearing and shear forces emphasize selecting materials with adequate compressive strength for bearing surfaces and sufficient shear strength to resist sliding failure. Engineers optimize joint geometry, such as hole diameter and edge distance, to distribute bearing loads effectively and minimize stress concentrations that cause shear failure. Proper allowance for load combinations and safety factors ensures structural integrity under varying conditions and dynamic forces.

Conclusion: Choosing the Right Force Analysis

Selecting the appropriate force analysis depends on the specific structural components and loading conditions, with bearing force concentrated on contact pressure between surfaces and shear force addressing the internal sliding resistance across a material plane. Accurate evaluation of bearing force ensures the prevention of surface deformation or crushing, while correct shear force analysis is critical for avoiding material failure due to sliding or shearing. Engineers must prioritize the dominant force type in their design calculations to enhance safety, durability, and overall performance of mechanical and structural systems.

Bearing force Infographic

libterm.com

libterm.com