The diesel cycle is a thermodynamic process that describes the operation of diesel engines, using compression ignition of fuel to produce power efficiently. It involves four stages: adiabatic compression, heat addition at constant pressure, adiabatic expansion, and heat rejection at constant volume. Discover how the diesel cycle optimizes engine performance and why it matters to your understanding of internal combustion engines by reading the full article.

Table of Comparison

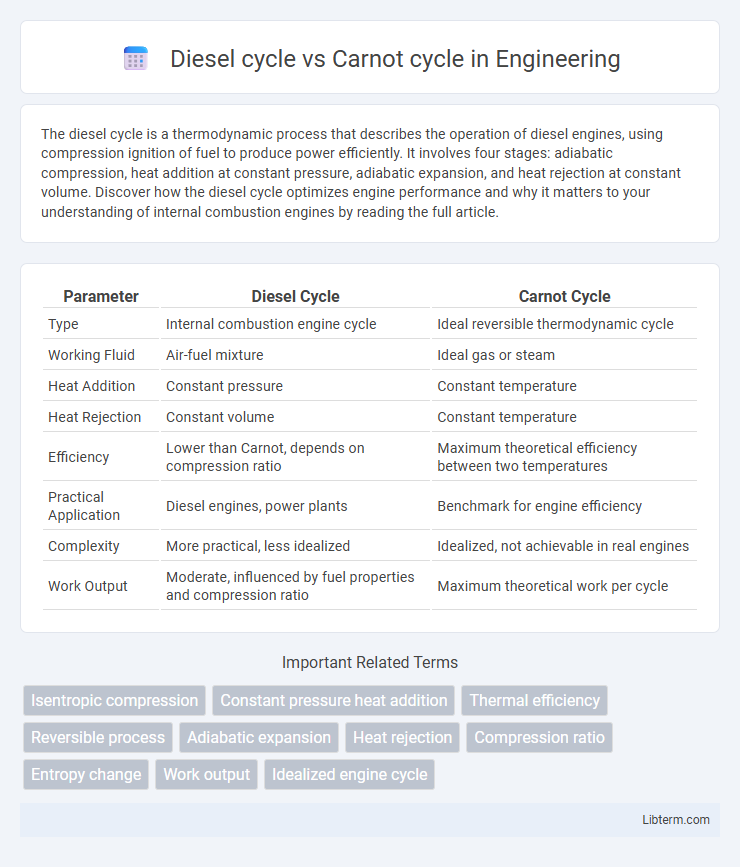

| Parameter | Diesel Cycle | Carnot Cycle |

|---|---|---|

| Type | Internal combustion engine cycle | Ideal reversible thermodynamic cycle |

| Working Fluid | Air-fuel mixture | Ideal gas or steam |

| Heat Addition | Constant pressure | Constant temperature |

| Heat Rejection | Constant volume | Constant temperature |

| Efficiency | Lower than Carnot, depends on compression ratio | Maximum theoretical efficiency between two temperatures |

| Practical Application | Diesel engines, power plants | Benchmark for engine efficiency |

| Complexity | More practical, less idealized | Idealized, not achievable in real engines |

| Work Output | Moderate, influenced by fuel properties and compression ratio | Maximum theoretical work per cycle |

Introduction to Diesel and Carnot Cycles

The Diesel cycle operates on the principle of constant pressure heat addition, commonly used in compression ignition engines for high efficiency and power output. The Carnot cycle represents an idealized reversible engine with maximum theoretical efficiency operating between two temperature reservoirs, serving as a benchmark for real engine cycles. Understanding the thermodynamic processes in Diesel and Carnot cycles highlights the practical versus theoretical performance in heat engines.

Fundamental Concepts of Thermodynamic Cycles

The Diesel cycle operates on a constant pressure heat addition process while the Carnot cycle involves isothermal heat addition and rejection, representing the most efficient theoretical cycle. Diesel cycles utilize compression ignition to convert chemical energy into work with less efficiency than the idealized Carnot cycle, which serves as the upper benchmark for thermodynamic efficiency. Understanding these fundamental differences aids in analyzing real-world engine performance versus idealized thermodynamic limits.

Key Components of the Diesel Cycle

The Diesel cycle includes four key components: the isentropic compression process, the constant pressure combustion process, the isentropic expansion process, and the constant volume exhaust process. High compression ratios ranging from 14:1 to 25:1 enable the Diesel cycle to achieve higher thermal efficiency compared to the Carnot cycle. The air-fuel mixture ignites due to compression-induced temperature increase rather than an external spark, differentiating it from other cycles and optimizing fuel utilization.

Key Components of the Carnot Cycle

The Carnot cycle operates through four key components: two isothermal processes where heat transfer occurs at constant temperatures, and two adiabatic processes involving no heat exchange that change the temperature and pressure of the working fluid. The isothermal expansion stage absorbs heat from a high-temperature reservoir, while the isothermal compression stage rejects heat to a low-temperature reservoir. The adiabatic expansion and compression stages connect these isothermal processes, ensuring the cycle operates reversibly and with maximum theoretical efficiency.

Step-by-Step Process Flow: Diesel vs Carnot Cycle

The Diesel cycle operates through four distinct steps: isentropic compression, constant-pressure heat addition, isentropic expansion, and constant-volume heat rejection, optimizing fuel efficiency in combustion engines. The Carnot cycle, an idealized thermodynamic cycle, involves two isothermal processes (heat addition and rejection) and two adiabatic processes (compression and expansion), representing maximum theoretical efficiency between two temperature reservoirs. Unlike the Carnot cycle's reversible heat exchanges, the Diesel cycle's practical combustion process leads to different efficiency and performance characteristics in real-world engine applications.

Efficiency Comparison: Diesel Cycle vs Carnot Cycle

The Carnot cycle achieves the highest theoretical efficiency between two temperature reservoirs, defined by 1 - (T_low/T_high), serving as an ideal benchmark. The Diesel cycle, used extensively in internal combustion engines, exhibits lower efficiency due to practical factors like irreversible processes and finite combustion rates. Typical Diesel cycle efficiency ranges between 30% to 45%, significantly below the ideal Carnot efficiency under comparable temperature limits.

Performance Analysis under Real-World Conditions

The Diesel cycle exhibits lower thermal efficiency than the ideal Carnot cycle due to inherent irreversibilities such as fuel injection delays and non-instantaneous combustion. Real-world performance of Diesel engines is further impacted by factors like variable compression ratios, heat losses, and friction, which deviate significantly from the Carnot cycle's assumptions of reversible processes and adiabatic heat transfer. Despite these limitations, the Diesel cycle maintains practical advantages in fuel efficiency and power output under variable loads, making it more suited for commercial and automotive applications compared to the theoretically ideal but practically unattainable Carnot cycle.

Practical Applications and Limitations

Diesel cycles are widely used in heavy-duty engines for trucks, ships, and industrial machinery due to their higher thermal efficiency and ability to operate under high compression ratios, which maximize fuel economy in practical applications. The Carnot cycle, while theoretically the most efficient, is impractical for real engines because it requires reversible processes and infinitely slow operations, limiting its use to idealized efficiency benchmarks rather than actual power generation. Diesel cycle engines face limitations such as higher emissions and mechanical stress, whereas Carnot cycle constraints prevent direct implementation in everyday combustion engines.

Advantages and Disadvantages of Each Cycle

The Diesel cycle offers higher thermal efficiency at high compression ratios due to its constant pressure heat addition, making it suitable for heavy-duty engines but results in higher NOx emissions and noise levels. The Carnot cycle represents an idealized engine with maximum possible efficiency between two temperatures, yet it is impractical for real engines because it requires reversible processes and infinite cycle time. Diesel engines provide better fuel economy and durability, while Carnot engines serve as theoretical benchmarks without direct applicability in actual machinery.

Conclusion: Choosing the Optimal Thermodynamic Cycle

The Diesel cycle offers practical advantages in efficiency and power output under high compression ratios, making it suitable for heavy-duty engines and real-world applications. The Carnot cycle, while representing the theoretical maximum efficiency for heat engines, is impractical due to idealized reversible processes and infinite time requirements. Selecting the optimal thermodynamic cycle depends on balancing efficiency, complexity, and operational constraints, with the Diesel cycle providing a realistic compromise between performance and feasibility.

Diesel cycle Infographic

libterm.com

libterm.com