Centrifugal compressors increase gas pressure by converting kinetic energy into potential energy through a spinning impeller that accelerates the fluid outward. They are widely used in industries such as HVAC, aerospace, and petrochemical processing for their efficiency and reliability in handling large volumes of gas. Explore the rest of this article to understand how centrifugal compressors can optimize Your systems and improve performance.

Table of Comparison

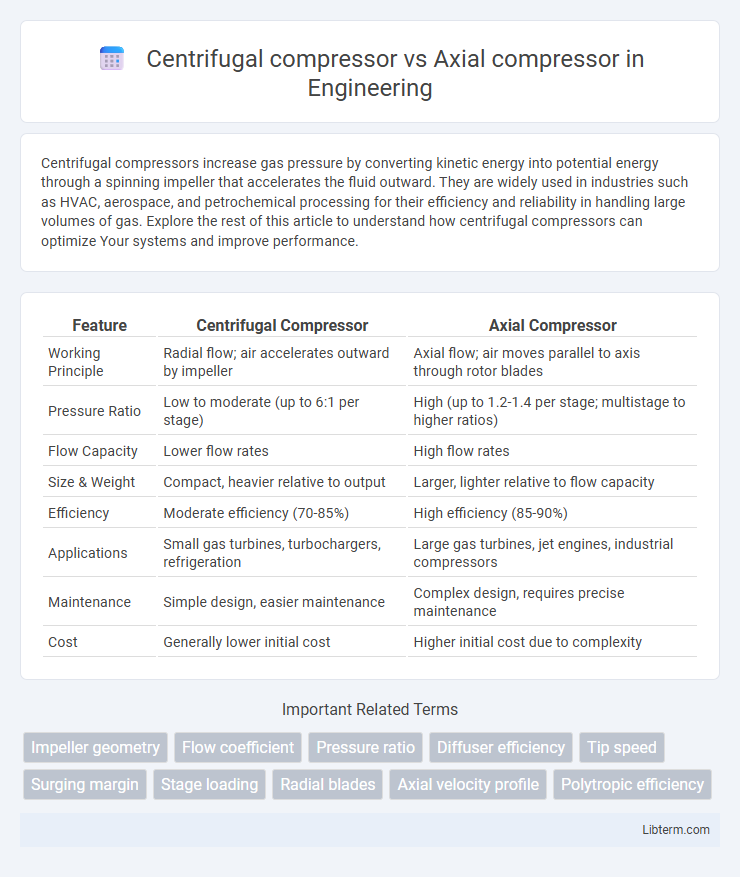

| Feature | Centrifugal Compressor | Axial Compressor |

|---|---|---|

| Working Principle | Radial flow; air accelerates outward by impeller | Axial flow; air moves parallel to axis through rotor blades |

| Pressure Ratio | Low to moderate (up to 6:1 per stage) | High (up to 1.2-1.4 per stage; multistage to higher ratios) |

| Flow Capacity | Lower flow rates | High flow rates |

| Size & Weight | Compact, heavier relative to output | Larger, lighter relative to flow capacity |

| Efficiency | Moderate efficiency (70-85%) | High efficiency (85-90%) |

| Applications | Small gas turbines, turbochargers, refrigeration | Large gas turbines, jet engines, industrial compressors |

| Maintenance | Simple design, easier maintenance | Complex design, requires precise maintenance |

| Cost | Generally lower initial cost | Higher initial cost due to complexity |

Introduction to Centrifugal and Axial Compressors

Centrifugal compressors increase gas velocity through radial acceleration, converting kinetic energy into pressure with a compact, single-stage design ideal for moderate pressure ratios. Axial compressors compress air by accelerating it axially through multiple stages of rotating and stationary blades, achieving higher pressure ratios and efficiency in large-scale applications. Both types are fundamental in gas turbine engines, HVAC systems, and industrial processes, with centrifugal compressors favored for simplicity and axial compressors for performance scalability.

Basic Operating Principles

Centrifugal compressors operate by drawing air into the center of a rotating impeller, where the air is accelerated outward by centrifugal force, increasing its velocity and pressure before passing through a diffuser for further pressure rise. Axial compressors consist of multiple stages of rotor and stator blades that progressively compress the air by continuously reducing the flow area, maintaining a primarily axial airflow direction throughout the process. The key difference lies in the radial flow and velocity increase in centrifugal compressors versus the axial flow and pressure rise through blade stages in axial compressors.

Key Design Differences

Centrifugal compressors feature a radial flow design where air enters axially and is expelled outward through the impeller, enabling high pressure rise per stage but limiting flow capacity. Axial compressors use multiple stages of rotating and stationary blades that progressively compress air along the axial direction, supporting higher flow rates and efficiency in large-scale applications. Key design differences include the centrifugal compressor's compact, robust impeller and simpler flow path compared to the axial compressor's complex blade geometry and multistage configuration for incremental pressure increases.

Performance Comparison

Centrifugal compressors deliver high pressure ratios per stage, typically ranging from 4:1 to 6:1, and are well-suited for low flow rates and compact designs. Axial compressors achieve higher flow capacities and overall efficiency, with pressure ratios up to 45:1 in multi-stage configurations, making them ideal for large-scale applications like jet engines and gas turbines. Performance is influenced by factors such as aerodynamic efficiency, operating speed, and maintenance complexity, with axial compressors generally outperforming centrifugal types in continuous high-flow operations.

Efficiency Analysis

Centrifugal compressors typically exhibit higher efficiency at lower flow rates due to their ability to generate higher pressure ratios per stage, making them ideal for smaller-scale applications. Axial compressors achieve greater overall efficiency at high flow rates and large-scale operations because of their streamlined airflow path and multiple stages. Efficiency analysis shows axial compressors maintain better aerodynamic performance and energy conversion efficiency in aerospace and large industrial settings, while centrifugal compressors offer simplicity and cost-effectiveness in moderate pressure ratio scenarios.

Applications and Industry Usage

Centrifugal compressors are widely used in industries requiring high pressure ratios and compact designs, such as chemical processing, refrigeration, and turbochargers for automotive engines. Axial compressors dominate in large-scale applications like jet engines, gas turbines, and power plants where high flow rates and efficiency are critical. Both compressor types serve crucial roles across aerospace, oil and gas, and HVAC sectors, tailored to specific operational demands and performance criteria.

Size and Weight Considerations

Centrifugal compressors are generally more compact and heavier per unit of airflow compared to axial compressors, making them suitable for smaller-scale applications with space constraints. Axial compressors, characterized by their longer and slimmer design, offer a higher flow capacity at a lighter weight for large-scale industrial and aerospace uses. The choice between centrifugal and axial compressors hinges on balancing size, weight, and performance requirements specific to the operational environment.

Maintenance and Reliability

Centrifugal compressors typically require less frequent maintenance due to their robust design and fewer moving parts, resulting in higher reliability for harsh operating conditions. Axial compressors demand more regular maintenance because of their complex blade assemblies and tighter clearances, which are more susceptible to wear and damage. Reliability in axial compressors depends heavily on precise alignment and blade condition, making predictive maintenance essential to prevent downtime.

Cost Analysis

Centrifugal compressors typically have lower initial manufacturing and maintenance costs compared to axial compressors due to simpler design and fewer stages. Axial compressors, though more expensive upfront, offer higher efficiency and better performance in large-scale applications, potentially reducing operational costs over time. Cost analysis must consider application scale, operational hours, and maintenance expenses to determine the most economical choice.

Choosing the Right Compressor

Choosing the right compressor depends on application requirements such as pressure ratio, flow rate, and space constraints. Centrifugal compressors excel in applications needing moderate flow and high-pressure ratios with compact design, often used in small gas turbines and HVAC systems. Axial compressors are preferred for high-flow, low-pressure-ratio scenarios like large power plants and jet engines, offering higher efficiency at scale but requiring more space.

Centrifugal compressor Infographic

libterm.com

libterm.com