Axial-flow compressors are widely used in jet engines due to their efficiency in handling large volumes of air with relatively low pressure increases per stage. These compressors operate by drawing air parallel to the axis of rotation, compressing it through multiple rotating and stationary blade stages. Explore the rest of the article to understand how axial-flow compressors enhance your engine's performance and reliability.

Table of Comparison

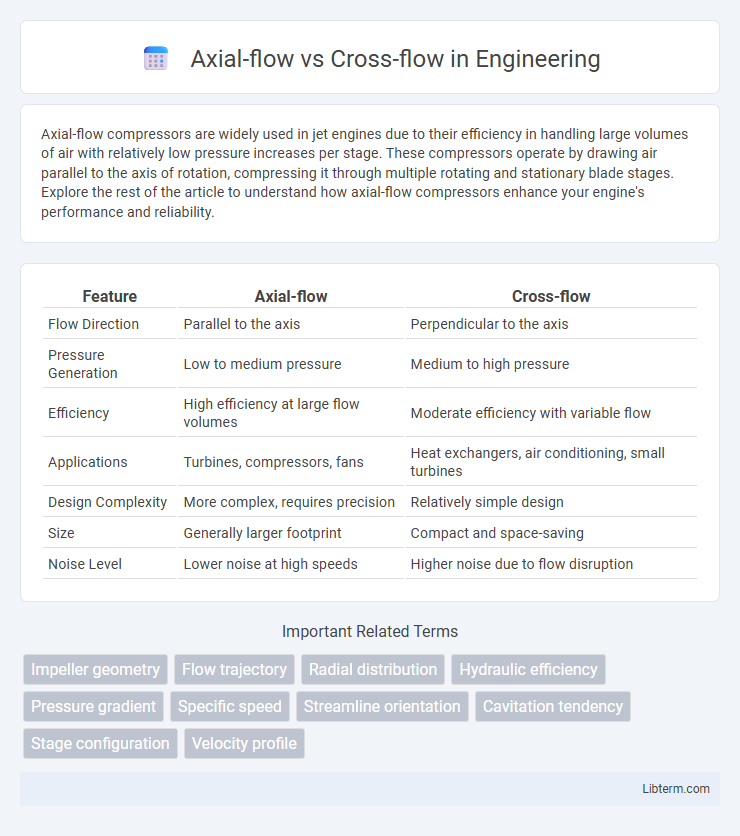

| Feature | Axial-flow | Cross-flow |

|---|---|---|

| Flow Direction | Parallel to the axis | Perpendicular to the axis |

| Pressure Generation | Low to medium pressure | Medium to high pressure |

| Efficiency | High efficiency at large flow volumes | Moderate efficiency with variable flow |

| Applications | Turbines, compressors, fans | Heat exchangers, air conditioning, small turbines |

| Design Complexity | More complex, requires precision | Relatively simple design |

| Size | Generally larger footprint | Compact and space-saving |

| Noise Level | Lower noise at high speeds | Higher noise due to flow disruption |

Introduction to Axial-Flow and Cross-Flow Technologies

Axial-flow and cross-flow technologies refer to different types of fluid movement in turbines and fans, where axial-flow moves fluid parallel to the axis of rotation, optimizing high flow rates and pressure efficiency. Cross-flow technology, often used in heat exchangers and turbines, directs fluid perpendicular to the axis, enhancing thermal exchange and uniform flow distribution. These distinct flow patterns influence design choices in energy systems, HVAC applications, and industrial processes for maximizing performance and efficiency.

Fundamental Principles of Axial-Flow Systems

Axial-flow systems operate by moving fluid parallel to the axis of rotation, enabling continuous high flow rates and efficient pressure rise in applications like turbines and compressors. The fundamental principle involves aerodynamic blade design that guides the fluid smoothly along the rotor's axis, minimizing turbulence and maximizing energy transfer. In contrast to cross-flow, axial-flow systems achieve greater efficiency in large-scale energy conversion processes due to their streamlined flow path and reduced flow separation.

Core Concepts Behind Cross-Flow Systems

Cross-flow systems operate by directing fluid perpendicular to the heat exchange surface, allowing the fluid to flow across the tube bundle, which enhances temperature gradient and heat transfer efficiency. The core concept involves maximizing the surface area contact and turbulent flow, leading to improved thermal performance compared to axial-flow systems where fluid flows parallel to the tubes. Cross-flow heat exchangers are widely used in cooling towers, air conditioners, and industrial processes due to their effective handling of large fluid volumes and ease of maintenance.

Design Differences: Axial-Flow vs Cross-Flow

Axial-flow turbines feature blades aligned parallel to the shaft, allowing fluid to flow along the axis, optimizing energy extraction in high-flow, low-head conditions. Cross-flow turbines, with fluid flowing perpendicular to the shaft through a cylindrical runner, excel in variable flow situations and simpler construction. Design differences influence their efficiency, installation complexity, and suitability for specific hydraulic conditions in hydroelectric power generation.

Performance and Efficiency Comparison

Axial-flow compressors typically offer higher pressure ratios and greater efficiency at high flow rates, making them ideal for large-scale gas turbines and jet engines. Cross-flow compressors, though less efficient with lower pressure ratios, provide compact design and simpler manufacturing, often suitable for small-scale applications and auxiliary power units. Performance metrics consistently show axial-flow technology excels in maintaining aerodynamic efficiency under varying operational conditions, whereas cross-flow configurations favor reduced maintenance costs and ease of integration.

Applications in Industry and Engineering

Axial-flow turbines excel in high-flow, low-pressure applications such as power generation in large-scale hydroelectric plants and jet engines, where their streamlined design efficiently converts kinetic energy into mechanical work. Cross-flow turbines, favored in low-head, variable-flow environments like small hydroelectric installations and water pumping systems, offer robust performance and simplicity, making them suitable for rural and off-grid power solutions. Industrial processes requiring compact and cost-effective energy conversion often utilize cross-flow designs, while axial-flow machines dominate sectors demanding high efficiency and large-scale energy output.

Advantages of Axial-Flow Mechanisms

Axial-flow mechanisms offer superior efficiency and higher flow rates, making them ideal for applications requiring large volumes of fluid or air movement with minimal energy consumption. Their streamlined design ensures lower pressure drops and reduced mechanical stress, enhancing durability and operational lifespan. These features make axial-flow systems preferable in industries such as HVAC, power generation, and aerospace for optimized performance and cost-effectiveness.

Benefits of Cross-Flow Configurations

Cross-flow configurations in heat exchangers enhance heat transfer efficiency by promoting better fluid mixing and more uniform temperature distribution. They offer flexibility in design, allowing for compact and lightweight systems ideal for space-constrained applications. Cross-flow designs also reduce fouling tendencies by maintaining higher turbulence levels, resulting in lower maintenance costs and improved operational reliability.

Key Factors in Selecting the Right Flow Type

Axial-flow fans excel in applications requiring high airflow with low pressure, ideal for ventilation and cooling systems, while cross-flow fans suit environments needing uniform airflow distribution over a wider area. Key factors when selecting between axial-flow and cross-flow include space constraints, noise levels, airflow direction, and efficiency at varying static pressures. Considering operational conditions such as required airflow volume, pressure requirements, and installation environment ensures optimal fan performance and energy efficiency.

Future Trends and Technological Advancements

Axial-flow turbines are advancing with improvements in blade aerodynamics and materials, enhancing efficiency in high-flow, low-head applications. Cross-flow turbines see innovation through modular designs and hybrid integration, optimizing performance in variable water conditions and small-scale hydro projects. Future trends emphasize smart monitoring systems and adaptive control technologies to maximize energy capture and operational reliability in both turbine types.

Axial-flow Infographic

libterm.com

libterm.com