Backflow occurs when contaminated water flows backward into the clean water supply, posing significant health risks and potential damage to plumbing systems. Understanding the causes and prevention methods of backflow is essential for maintaining water safety and compliance with regulations. Explore the rest of this article to learn how you can protect your water supply from backflow hazards effectively.

Table of Comparison

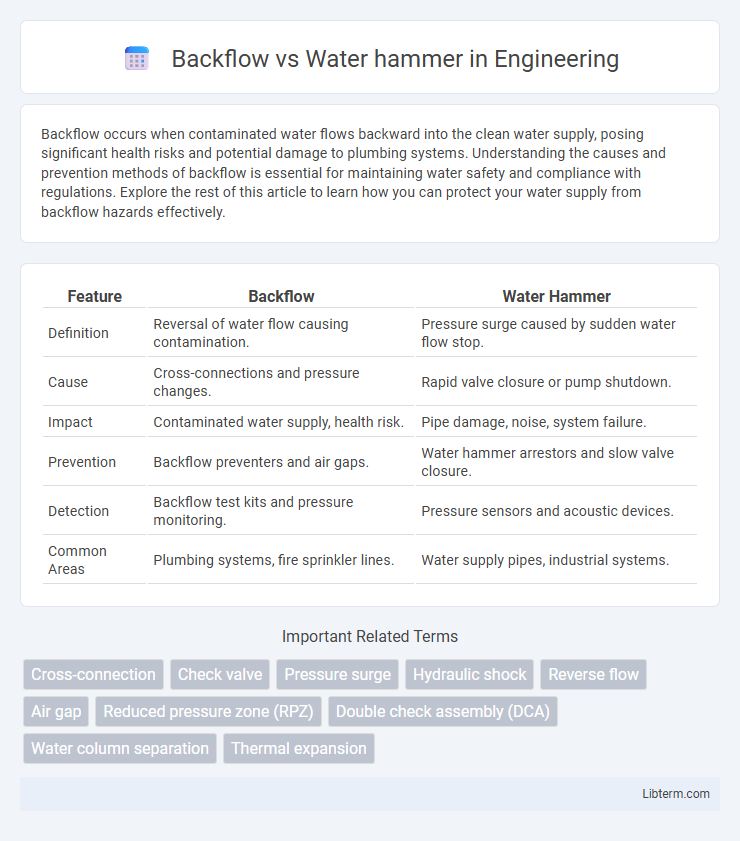

| Feature | Backflow | Water Hammer |

|---|---|---|

| Definition | Reversal of water flow causing contamination. | Pressure surge caused by sudden water flow stop. |

| Cause | Cross-connections and pressure changes. | Rapid valve closure or pump shutdown. |

| Impact | Contaminated water supply, health risk. | Pipe damage, noise, system failure. |

| Prevention | Backflow preventers and air gaps. | Water hammer arrestors and slow valve closure. |

| Detection | Backflow test kits and pressure monitoring. | Pressure sensors and acoustic devices. |

| Common Areas | Plumbing systems, fire sprinkler lines. | Water supply pipes, industrial systems. |

Understanding Backflow: Definition and Causes

Backflow occurs when contaminated water flows backward into the clean water supply, posing health risks and compromising water quality. Causes of backflow include pressure drops in the supply system, cross-connections between potable and non-potable sources, and backpressure conditions from pumps or elevated tanks. Understanding these factors is critical for preventing contamination and ensuring safe drinking water in plumbing systems.

Water Hammer Explained: What It Is and How It Happens

Water hammer is a pressure surge that occurs when a fluid in motion is forced to stop or change direction suddenly, creating shock waves in plumbing systems. This phenomenon typically happens when valves close abruptly or pumps shut off quickly, causing pipes to vibrate and generate loud banging noises. Understanding water hammer helps prevent damage such as pipe bursts and joint failures by implementing solutions like air chambers or pressure relief valves.

Key Differences Between Backflow and Water Hammer

Backflow occurs when contaminated water flows backward into the clean water supply, posing health risks primarily caused by changes in pressure or cross-connections, while water hammer is a hydraulic shockwave resulting from the sudden stoppage of water flow in pipes, leading to noise and potential pipe damage. The key difference lies in their causes and effects: backflow compromises water quality and safety, whereas water hammer affects the physical integrity of the plumbing system. Understanding these distinctions is essential for implementing appropriate prevention measures such as backflow preventers for contamination and water hammer arrestors for pressure surges.

Common Sources of Backflow in Plumbing Systems

Common sources of backflow in plumbing systems include cross-connections between potable and non-potable water lines, such as garden hose attachments and faulty irrigation systems. Contaminants can enter drinking water when a drop in pressure causes reverse flow, often due to water main breaks or firefighting activities. Proper installation of backflow preventers and routine maintenance are essential to protect water quality and prevent contamination.

Typical Triggers of Water Hammer in Pipes

Water hammer typically occurs in pipes due to sudden changes in water flow velocity caused by rapid valve closure, pump startups or shutdowns, and quick changes in direction caused by check valves. Pressure surges created by these abrupt flow alterations generate shock waves that can damage pipe joints and fixtures. Controlling water hammer often involves installing air chambers, water hammer arrestors, or pressure relief valves to absorb and dissipate these pressure spikes.

Health Risks Associated with Backflow

Backflow occurs when contaminated water reverses flow into the potable water supply, posing significant health risks such as exposure to harmful bacteria, viruses, and chemicals leading to waterborne diseases. Unlike water hammer, which primarily causes mechanical damage through pressure surges, backflow directly contaminates drinking water systems, increasing the likelihood of gastrointestinal illnesses and other infection-related health issues. Preventing backflow through devices like air gaps and backflow preventers is essential for maintaining safe drinking water and protecting public health.

Damage Risks from Water Hammer Events

Water hammer events generate sudden pressure surges that can cause significant damage to pipes, fittings, and valves, leading to leaks, bursts, or system failures. Unlike backflow, which primarily risks contamination by reversing water flow, water hammer's high-impact pressure pulses stress plumbing components, accelerating wear and reducing system lifespan. Effective mitigation requires installation of air chambers, water hammer arrestors, or pressure relief valves to absorb shock and protect infrastructure integrity.

Prevention Methods for Backflow Issues

Effective prevention methods for backflow issues include installing backflow preventers such as double check valves and reduced pressure zone assemblies to ensure water flows in one direction. Regular maintenance and testing of these devices are crucial to avoid contamination of potable water supplies. Proper system design with adequate air gaps and pressure regulation further minimizes the risk of backflow incidents.

Solutions to Minimize Water Hammer Effects

Installing water hammer arrestors near quick-closing valves effectively absorbs shock waves, reducing pipe stress and noise. Using air chambers and proper pipe sizing further mitigates pressure surges by providing cushioning space for water movement. Regular maintenance of valves and gradual valve closure techniques also help prevent sudden pressure changes that cause water hammer.

Comparing Diagnostic and Repair Techniques

Backflow diagnosis involves pressure testing and inspecting check valves to identify contamination risks, while water hammer focuses on detecting pressure surges through acoustic sensors and pressure gauges. Repair techniques for backflow typically require installing or servicing backflow preventers, whereas water hammer mitigation often involves installing air chambers, water hammer arrestors, or adjusting system pressures. Both conditions demand precise troubleshooting but differ fundamentally in diagnostic tools and repair approaches due to the unique nature of fluid dynamics involved.

Backflow Infographic

libterm.com

libterm.com