Experimental testing provides critical insights by systematically evaluating hypotheses under controlled conditions to validate theories or products. This method enhances the accuracy of results through repeated trials and objective measurement, ensuring reliable data. Explore the rest of the article to understand how experimental testing can optimize your research or development process.

Table of Comparison

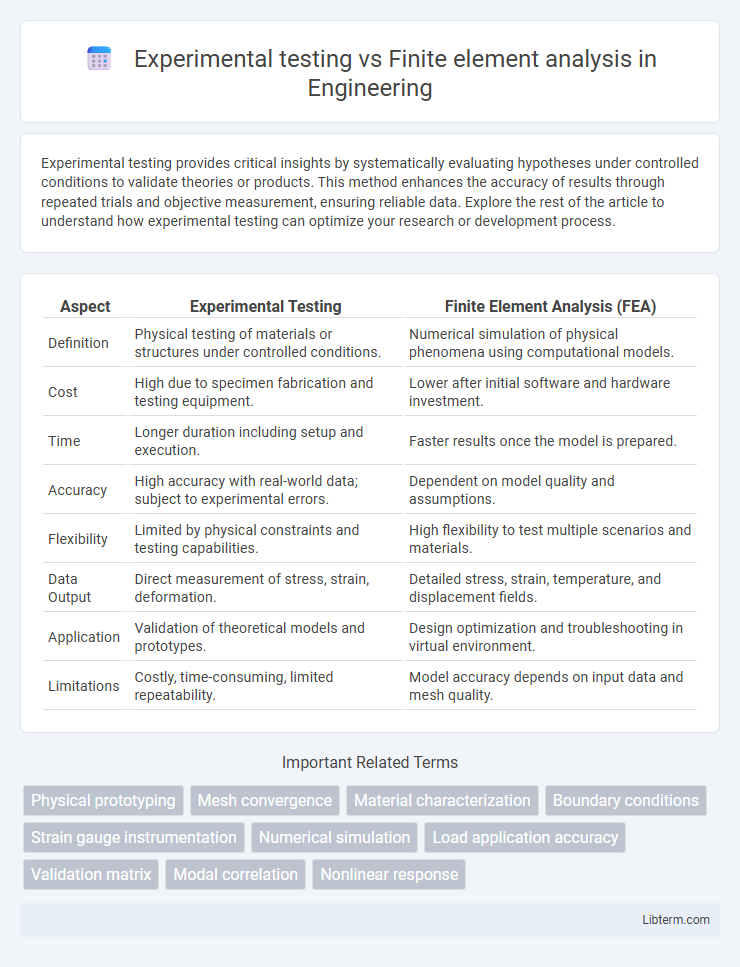

| Aspect | Experimental Testing | Finite Element Analysis (FEA) |

|---|---|---|

| Definition | Physical testing of materials or structures under controlled conditions. | Numerical simulation of physical phenomena using computational models. |

| Cost | High due to specimen fabrication and testing equipment. | Lower after initial software and hardware investment. |

| Time | Longer duration including setup and execution. | Faster results once the model is prepared. |

| Accuracy | High accuracy with real-world data; subject to experimental errors. | Dependent on model quality and assumptions. |

| Flexibility | Limited by physical constraints and testing capabilities. | High flexibility to test multiple scenarios and materials. |

| Data Output | Direct measurement of stress, strain, deformation. | Detailed stress, strain, temperature, and displacement fields. |

| Application | Validation of theoretical models and prototypes. | Design optimization and troubleshooting in virtual environment. |

| Limitations | Costly, time-consuming, limited repeatability. | Model accuracy depends on input data and mesh quality. |

Introduction to Experimental Testing and Finite Element Analysis

Experimental testing involves physically subjecting materials or structures to controlled conditions to observe their behavior, providing direct, empirical data on performance and failure modes. Finite Element Analysis (FEA) is a computational method that simulates and predicts how a product reacts to real-world forces, heat, vibration, and other physical effects by breaking down complex structures into smaller, manageable elements. Combining experimental testing with FEA enhances accuracy in design validation, enabling engineers to optimize performance and predict potential issues before manufacturing.

Fundamental Principles of Experimental Testing

Experimental testing relies on direct physical measurement and observation to evaluate material behavior and structural response, employing controlled environments and standardized procedures such as strain gauges, load cells, and displacement sensors. It uses fundamental principles of mechanics and material science to validate hypotheses and calibrate models by capturing real-world nonlinearities, failure modes, and boundary conditions. Experimental testing serves as a critical benchmark to verify the accuracy and reliability of finite element analysis (FEA) predictions by providing empirical data for model validation and error quantification.

Core Concepts of Finite Element Analysis

Finite Element Analysis (FEA) is a computational technique that subdivides complex structures into smaller, manageable elements to simulate physical behaviors under various conditions. Core concepts include mesh generation, element types, boundary conditions, and solving systems of equations to approximate stress, strain, and deformation. Experimental testing provides empirical validation for FEA models, ensuring accuracy by comparing predicted results with physical measurements.

Comparative Benefits of Experimental Testing

Experimental testing provides direct, real-world validation of material behavior and structural performance under actual service conditions, capturing complex phenomena that may be oversimplified or missed in Finite Element Analysis (FEA). It identifies unforeseen failure modes and verifies the accuracy of computational models, ensuring reliability and safety in engineering designs. Experimental methods are indispensable for calibrating FEA models, enhancing their predictive capability through empirical data integration.

Advantages and Limitations of Finite Element Analysis

Finite Element Analysis (FEA) offers precise simulation of complex structures under various conditions, enabling cost-effective and rapid testing compared to Experimental Testing. FEA allows detailed visualization of stress distribution and deformation, but its accuracy depends heavily on the quality of the mesh, material models, and boundary conditions, which may lead to errors if not properly defined. While Experimental Testing provides real-world validation, FEA excels in optimizing designs early in the development process and reducing the need for multiple physical prototypes.

Accuracy and Reliability: Lab Results vs Simulation

Experimental testing provides high accuracy by generating real-world data under controlled conditions, capturing complex material behaviors and environmental influences that simulations may overlook. Finite element analysis (FEA) offers repeatable, reliable predictions through numerical modeling but depends heavily on assumptions, mesh quality, and material property inputs, which can introduce uncertainties. Combining lab results with FEA validation enhances overall reliability, allowing for calibration of models and improved accuracy in predicting structural performance.

Cost and Time Considerations for Both Approaches

Experimental testing often involves higher costs and longer time frames due to the need for physical prototypes, materials, and labor-intensive setup procedures. Finite element analysis (FEA) significantly reduces expenses and accelerates project timelines by allowing virtual simulation and rapid modifications without material consumption. The initial software investment and expertise required for FEA can be offset by its efficiency in iterative design and minimized risk of costly rework during product development.

Real-World Applications and Case Studies

Experimental testing provides empirical data critical for validating materials, structural components, and systems under actual operating conditions, ensuring reliability in aerospace, automotive, and civil engineering projects. Finite element analysis (FEA) complements physical experiments by simulating complex behaviors and stress distributions in designs that are costly or impractical to test physically, as demonstrated in case studies involving bridge load assessments and crashworthiness evaluations. Integrating experimental results with FEA models enhances accuracy in predictive maintenance, optimizing performance and safety in industries such as biomedical implants and offshore structures.

Bridging Gaps: Combining Physical Testing and FEA

Bridging gaps between experimental testing and finite element analysis (FEA) enhances the accuracy and reliability of structural evaluations by validating simulation results with real-world data. Experimental testing reveals material behaviors, boundary conditions, and failure modes that improve FEA models through calibration and refinement, reducing uncertainties. Integrating physical testing with FEA accelerates innovation in engineering design, ensuring safer and more efficient performance predictions across aerospace, automotive, and civil infrastructure industries.

Future Trends in Structural Analysis Methods

Future trends in structural analysis methods emphasize hybrid approaches combining experimental testing with finite element analysis (FEA) to enhance accuracy and predictive capabilities. Advances in machine learning integration and real-time sensor data incorporation enable adaptive modeling and immediate validation, reducing reliance on traditional exhaustive physical prototypes. Emerging developments in high-performance computing and multi-scale simulations aim to improve the resolution and efficiency of FEA, facilitating complex structural behavior analysis under dynamic loading conditions.

Experimental testing Infographic

libterm.com

libterm.com