Computational modeling simulates complex systems using mathematical algorithms and computer simulations to predict behaviors and outcomes. It plays a crucial role in fields such as engineering, biology, and economics by allowing researchers to test hypotheses and analyze data efficiently. Explore the rest of this article to understand how computational modeling can enhance your problem-solving capabilities.

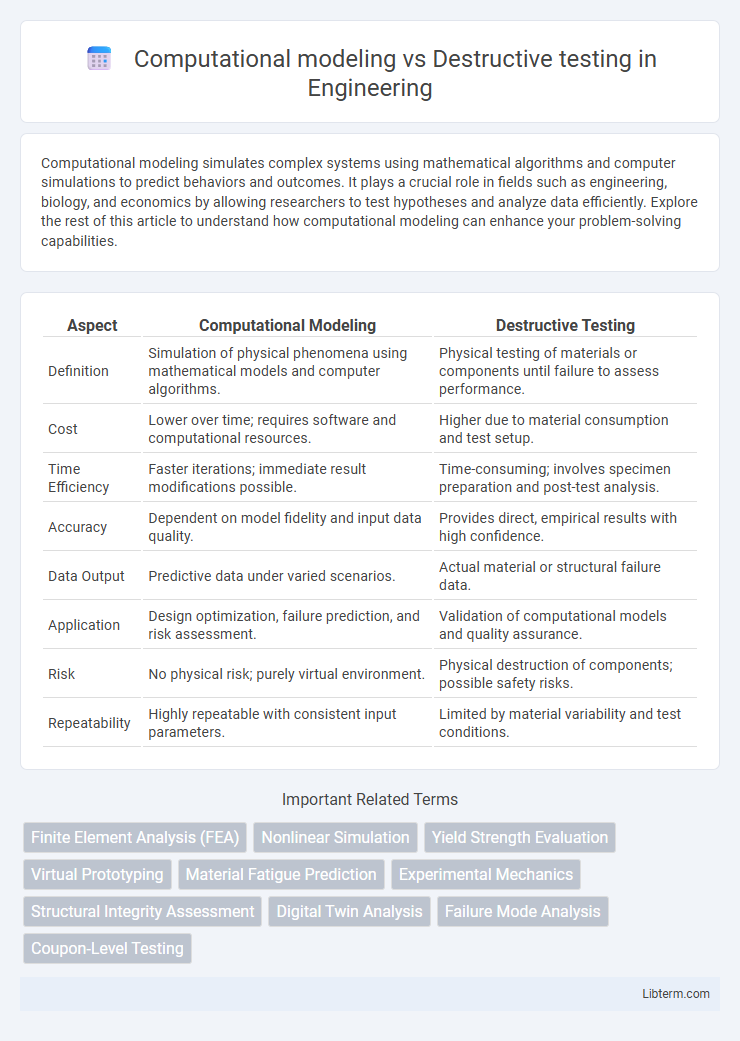

Table of Comparison

| Aspect | Computational Modeling | Destructive Testing |

|---|---|---|

| Definition | Simulation of physical phenomena using mathematical models and computer algorithms. | Physical testing of materials or components until failure to assess performance. |

| Cost | Lower over time; requires software and computational resources. | Higher due to material consumption and test setup. |

| Time Efficiency | Faster iterations; immediate result modifications possible. | Time-consuming; involves specimen preparation and post-test analysis. |

| Accuracy | Dependent on model fidelity and input data quality. | Provides direct, empirical results with high confidence. |

| Data Output | Predictive data under varied scenarios. | Actual material or structural failure data. |

| Application | Design optimization, failure prediction, and risk assessment. | Validation of computational models and quality assurance. |

| Risk | No physical risk; purely virtual environment. | Physical destruction of components; possible safety risks. |

| Repeatability | Highly repeatable with consistent input parameters. | Limited by material variability and test conditions. |

Introduction to Computational Modeling and Destructive Testing

Computational modeling uses advanced algorithms and simulations to predict the behavior and performance of materials or structures under various conditions, enabling virtual testing and optimization. Destructive testing involves physically subjecting materials or components to stress until failure to directly assess their strength, durability, and failure modes. Combining computational models with destructive testing data enhances accuracy in product design and safety evaluations.

Fundamental Principles of Computational Modeling

Computational modeling relies on mathematical algorithms and numerical methods to simulate physical phenomena, enabling the analysis of complex systems without physical interference. It utilizes finite element analysis, computational fluid dynamics, and other simulation techniques grounded in physics and material science principles to predict performance and behavior under various conditions. Unlike destructive testing, which physically damages specimens to assess failure modes, computational modeling offers a cost-effective, efficient, and non-invasive alternative for testing and design validation.

Core Concepts of Destructive Testing

Destructive testing involves physically evaluating a material or component by subjecting it to conditions until failure occurs, providing direct insights into mechanical properties such as tensile strength, hardness, and impact resistance. This method contrasts with computational modeling, which simulates material behavior using mathematical algorithms without material damage, often predicting performance under various conditions. Key aspects of destructive testing include sample preparation, controlled load application, and failure analysis, ensuring accurate and empirical data critical for validating design specifications and safety standards.

Comparative Analysis: Accuracy and Reliability

Computational modeling offers high accuracy in predicting structural behavior through advanced algorithms and simulations, enabling detailed analysis of stress, strain, and failure modes without physical prototypes. Destructive testing provides empirical data that validates these models by physically subjecting materials or components to failure, offering reliable real-world performance insights but at higher costs and time consumption. Combining computational modeling with destructive testing enhances reliability, as simulations can be calibrated and verified against experimental results, improving predictive accuracy for engineering applications.

Cost and Time Efficiency Considerations

Computational modeling significantly reduces costs and time compared to destructive testing by simulating multiple scenarios without material waste or physical setup expenses. Destructive testing incurs higher expenses due to sample preparation, labor, and equipment wear, often requiring extensive time for each test iteration. Efficient computational methods accelerate product development cycles while minimizing resource usage, making them ideal for early-stage analysis and optimization.

Application Areas and Industry Use Cases

Computational modeling excels in aerospace and automotive industries for simulating stress and predicting failure points, significantly reducing prototyping costs and development time. Destructive testing is predominantly applied in construction and manufacturing sectors to verify material strength and compliance with safety standards under actual load conditions. Both methods complement quality assurance processes, with computational modeling enabling virtual scenarios and destructive testing providing empirical validation.

Environmental Impact and Resource Consumption

Computational modeling significantly reduces environmental impact by minimizing the need for physical prototypes, thereby lowering material waste, energy consumption, and emissions associated with manufacturing and testing processes. Destructive testing requires extensive use of raw materials and generates waste, contributing to resource depletion and environmental pollution. Advances in simulation software enable engineers to predict product performance more sustainably, optimizing resource utilization and decreasing ecological footprints.

Data Interpretation and Result Validation

Computational modeling enables precise data interpretation by simulating various conditions and predicting outcomes with high reproducibility, while destructive testing provides direct empirical results through physical experimentation, offering tangible evidence of material or system behavior. Result validation in computational modeling relies heavily on comparison with established experimental data, often derived from destructive testing benchmarks, to ensure accuracy and reliability. Integrating data from both methods enhances confidence in findings, as computational predictions are refined with real-world physical test outcomes.

Future Trends in Material Testing

Computational modeling is advancing rapidly with the integration of artificial intelligence and machine learning, enabling predictive simulations that reduce reliance on costly and time-consuming destructive testing methods. Future trends emphasize hybrid approaches combining real-time sensor data with digital twins to enhance accuracy and accelerate material performance evaluation. Emerging techniques prioritize sustainability by minimizing test samples, leveraging virtual material design, and optimizing lifecycle assessments for next-generation composites and alloys.

Integrating Computational and Destructive Methods

Integrating computational modeling with destructive testing enhances material analysis by combining accurate simulation data with real-world validation, improving reliability and reducing experimental costs. Computational models predict failure mechanisms and stress distributions, while destructive testing provides empirical evidence to refine these simulations, ensuring higher fidelity in material performance assessment. This hybrid approach accelerates design optimization, supports certification processes, and fosters innovation in engineering applications.

Computational modeling Infographic

libterm.com

libterm.com