Annealing is a heat treatment process that alters the microstructure of materials like metals and glass to improve their ductility and reduce hardness. It involves heating the material to a specific temperature, maintaining that temperature, and then cooling it slowly to relieve internal stresses. Discover how annealing can enhance your material's properties and explore the detailed process and applications in the rest of this article.

Table of Comparison

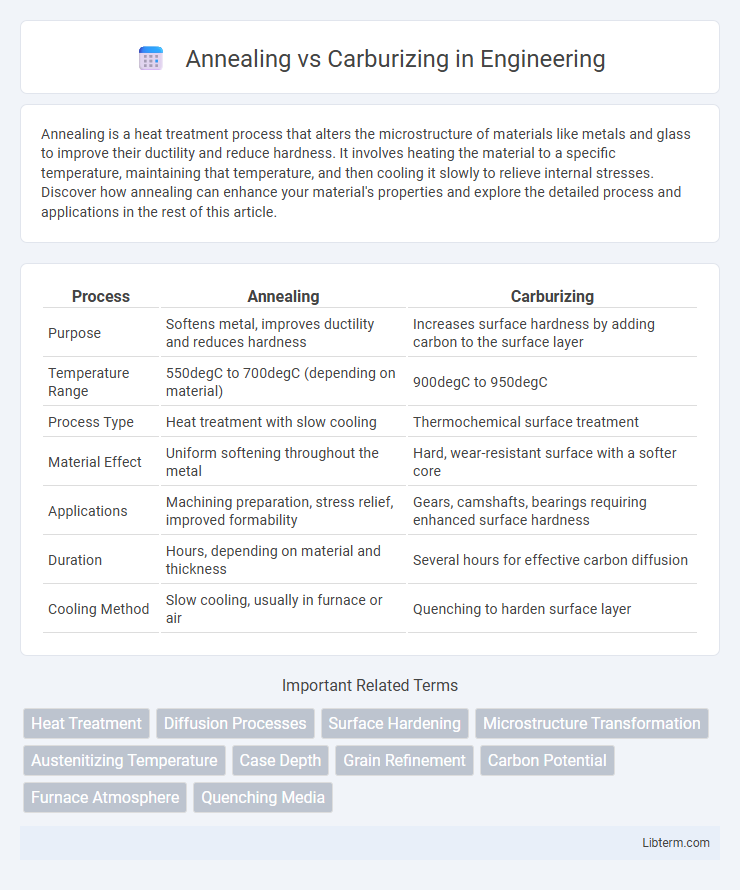

| Process | Annealing | Carburizing |

|---|---|---|

| Purpose | Softens metal, improves ductility and reduces hardness | Increases surface hardness by adding carbon to the surface layer |

| Temperature Range | 550degC to 700degC (depending on material) | 900degC to 950degC |

| Process Type | Heat treatment with slow cooling | Thermochemical surface treatment |

| Material Effect | Uniform softening throughout the metal | Hard, wear-resistant surface with a softer core |

| Applications | Machining preparation, stress relief, improved formability | Gears, camshafts, bearings requiring enhanced surface hardness |

| Duration | Hours, depending on material and thickness | Several hours for effective carbon diffusion |

| Cooling Method | Slow cooling, usually in furnace or air | Quenching to harden surface layer |

Introduction to Annealing and Carburizing

Annealing is a heat treatment process that softens metal, improves its ductility, and reduces internal stresses by heating the material to a specific temperature and then cooling it slowly. Carburizing is a surface hardening technique where carbon is diffused into the outer layer of steel at high temperatures, enhancing surface hardness while maintaining a tougher core. Both processes are essential in metallurgy but serve distinct purposes: annealing for material softening and stress relief, and carburizing for hardness and wear resistance.

Understanding the Heat Treatment Processes

Annealing involves heating a metal to a specific temperature and then slowly cooling it to soften the material, enhance ductility, and relieve internal stresses. Carburizing is a case-hardening process where steel is exposed to a carbon-rich environment at high temperatures, allowing carbon atoms to diffuse into the surface, increasing hardness and wear resistance. Both heat treatment processes alter the microstructure of metals but serve distinct purposes: annealing improves machinability and toughness, while carburizing enhances surface durability without compromising the core's toughness.

Key Objectives: Annealing vs Carburizing

Annealing primarily aims to soften metal, enhance ductility, and relieve internal stresses through controlled heating and slow cooling. Carburizing focuses on increasing surface hardness by infusing carbon into the metal's outer layer, improving wear resistance while maintaining a tough core. Both heat treatment processes optimize metal properties but target different mechanical enhancements for specific industrial applications.

Fundamental Mechanisms of Annealing

Annealing involves heating a metal to a specific temperature and then slowly cooling it to alter its microstructure, primarily to reduce hardness, relieve internal stresses, and improve ductility. The fundamental mechanism includes recovery, recrystallization, and grain growth processes that restore the metal's crystalline structure after deformation. In contrast, carburizing introduces carbon into the surface layer of a steel alloy at high temperatures to increase surface hardness without significantly affecting the core properties.

Carburizing: Process and Purpose

Carburizing is a heat treatment process that introduces carbon into the surface layer of low-carbon steel to enhance hardness and wear resistance while preserving a tough core. This is achieved by heating the steel in a carbon-rich environment, typically at temperatures between 900degC and 950degC, allowing carbon atoms to diffuse into the metal surface. The primary purpose of carburizing is to improve fatigue strength and extend the service life of components such as gears, camshafts, and bearings by creating a hard, wear-resistant outer layer.

Materials Best Suited for Each Process

Annealing is best suited for ferrous metals such as carbon steels and cast irons, where it improves ductility and reduces internal stresses by heating the material to a specific temperature and then cooling it slowly. Carburizing is ideal for low-carbon steels, enhancing surface hardness by diffusing carbon into the material's surface at high temperatures, making it perfect for components requiring wear resistance like gears and shafts. Each process targets different material properties, with annealing focused on structural refinement and carburizing on surface hardness enhancement.

Comparative Effects on Microstructure

Annealing refines grain structure by promoting uniform recrystallization, resulting in a softened, ductile microstructure with reduced internal stresses. Carburizing introduces a high-carbon surface layer, creating a hardened microstructure with a tough core through the formation of martensite after quenching. The comparative effect on microstructure highlights annealing's role in enhancing machinability and toughness, while carburizing significantly increases surface hardness and wear resistance.

Influence on Mechanical Properties

Annealing enhances ductility and reduces hardness by relieving internal stresses and refining microstructure, resulting in improved toughness and machinability. Carburizing increases surface hardness and wear resistance by diffusing carbon into the steel surface, creating a hard, wear-resistant case while maintaining a tough, ductile core. The combination of these heat treatments allows for tailored mechanical properties suitable for high-stress applications requiring both surface durability and core toughness.

Industrial Applications of Annealing and Carburizing

Annealing is widely used in industrial applications to improve metal ductility, reduce hardness, and relieve internal stresses in steel components, enhancing machinability and extending tool life. Carburizing is employed in industries requiring hard, wear-resistant surfaces on low-carbon steel parts, such as gears, shafts, and bearings, by diffusing carbon into the metal surface to increase hardness and fatigue strength. Both heat treatment processes are critical in manufacturing sectors like automotive, aerospace, and heavy machinery, where material performance and durability are paramount.

Choosing the Right Process: Factors and Recommendations

Choosing between annealing and carburizing depends on the desired mechanical properties and application requirements. Annealing is ideal for reducing hardness and improving ductility in metals, enhancing machinability and relieving internal stresses, while carburizing is suited for increasing surface hardness and wear resistance by adding carbon to the outer layer. Factors such as component hardness, wear resistance needs, and cost-effectiveness guide the selection process, with annealing recommended for softening and stress relief, and carburizing preferred for components subjected to high surface wear.

Annealing Infographic

libterm.com

libterm.com