Leaf springs provide reliable support and load distribution for vehicle suspension systems, ensuring a smooth and stable ride under varying road conditions. Made of layered steel strips, they efficiently absorb shocks and maintain axle alignment, enhancing durability and safety. Explore the full article to understand how leaf springs optimize your vehicle's performance and longevity.

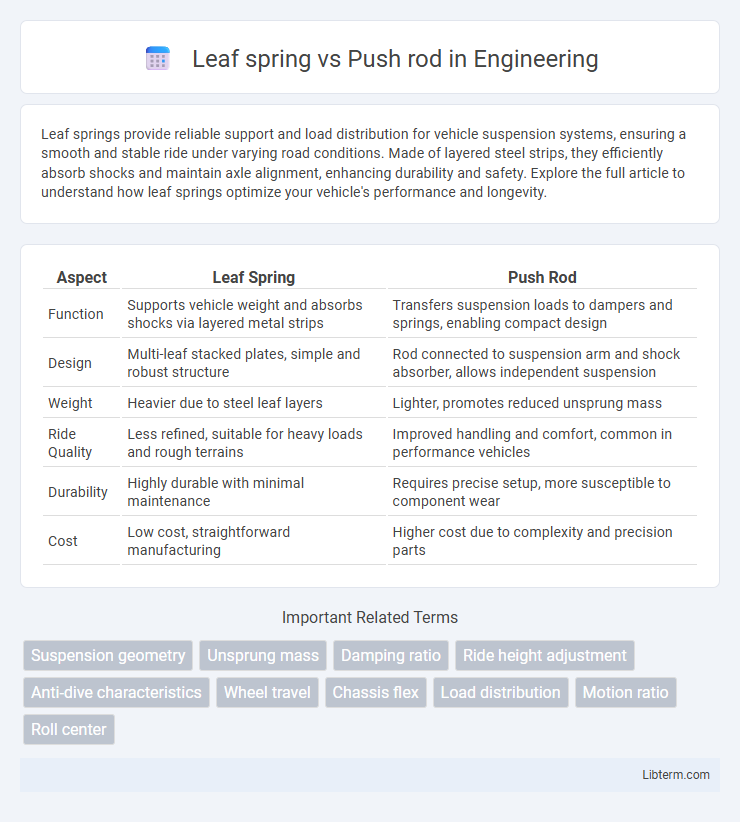

Table of Comparison

| Aspect | Leaf Spring | Push Rod |

|---|---|---|

| Function | Supports vehicle weight and absorbs shocks via layered metal strips | Transfers suspension loads to dampers and springs, enabling compact design |

| Design | Multi-leaf stacked plates, simple and robust structure | Rod connected to suspension arm and shock absorber, allows independent suspension |

| Weight | Heavier due to steel leaf layers | Lighter, promotes reduced unsprung mass |

| Ride Quality | Less refined, suitable for heavy loads and rough terrains | Improved handling and comfort, common in performance vehicles |

| Durability | Highly durable with minimal maintenance | Requires precise setup, more susceptible to component wear |

| Cost | Low cost, straightforward manufacturing | Higher cost due to complexity and precision parts |

Introduction to Suspension Systems

Leaf springs provide a simple, durable suspension solution primarily used in trucks and heavy-duty vehicles, offering load-bearing capacity through stacked metal strips that flex under pressure. Push rod suspension systems, common in high-performance and race cars, utilize rods to transfer forces from the wheel to inboard springs and dampers, enhancing handling and ride quality. These designs reflect different approaches to managing vehicle dynamics, with leaf springs focusing on strength and load distribution, while push rods prioritize precision and weight reduction.

Overview of Leaf Spring Technology

Leaf spring technology uses stacked layers of flexible steel strips to absorb shocks and support vehicle weight, providing a durable and cost-effective suspension solution primarily in trucks and heavy-duty vehicles. The design allows for load distribution along the length of the spring, enhancing stability and reducing stress on axles. Leaf springs require less maintenance compared to push rod systems and are favored for their simplicity and ability to handle heavy loads efficiently.

Fundamentals of Push Rod Suspension

Push rod suspension systems use a push rod to transfer wheel movement to the spring and damper, typically mounted inboard to reduce unsprung mass and improve handling. This setup contrasts with traditional leaf spring suspensions, which integrate the spring and axle connection directly, often resulting in higher unsprung weight and less precise control. The fundamental advantage of push rod suspensions lies in their ability to optimize suspension geometry for better ride quality and vehicle dynamics in high-performance applications.

Key Differences Between Leaf Spring and Push Rod

Leaf springs are traditional suspension components made of stacked metal strips that provide load-bearing support and shock absorption, commonly used in trucks and heavy-duty vehicles. Push rods, typically found in high-performance and racing suspension systems, transfer force from the wheel to the shock absorber or spring, enabling precise handling and adjustable ride characteristics. The key differences lie in their design, application, and performance: leaf springs integrate load support and damping in one unit, whereas push rods separate these functions for improved suspension tuning and responsiveness.

Advantages of Leaf Spring Suspension

Leaf spring suspension offers advantages such as simplicity in design, leading to lower manufacturing and maintenance costs. Its robust structure provides excellent load-bearing capacity and durability, making it ideal for heavy-duty vehicles. The integrated function of springs and shock absorbers in leaf springs enhances stability and ride comfort on rough terrains.

Benefits of Push Rod Suspension

Push rod suspension offers superior handling and ride quality by relocating suspension components inboard, reducing unsprung weight for enhanced vehicle responsiveness. It allows precise tuning of suspension geometry, improving tire contact and grip during dynamic driving conditions. The compact design also contributes to better aerodynamics and weight distribution, making it a preferred choice for high-performance and racing applications.

Application in Automotive and Motorsport

Leaf springs are extensively utilized in heavy-duty automotive applications and off-road vehicles for their durability and ability to handle substantial loads with simplicity and lower maintenance. Push rod suspension systems are favored in high-performance motorsport applications due to their precise handling, reduced unsprung mass, and ability to optimize suspension geometry for enhanced aerodynamics and responsiveness. The choice between leaf spring and push rod largely depends on vehicle weight, desired handling characteristics, and the specific demands of racing or commercial use.

Performance Comparison: Leaf Spring vs Push Rod

Leaf springs provide robust load-bearing capabilities and durability, making them suitable for heavy-duty vehicles, while push rods offer superior handling and responsiveness due to their lighter weight and improved suspension geometry. Push rod suspension systems typically enhance ride quality and precision by allowing for better shock absorber placement and reduced unsprung mass. Performance-wise, leaf springs excel in load support and simplicity, whereas push rods deliver significant advantages in dynamic driving performance and adjustability.

Cost and Maintenance Considerations

Leaf springs generally offer lower initial costs and simpler maintenance due to their straightforward design and fewer components, making them ideal for budget-conscious applications. Push rod suspension systems, while providing superior performance and handling, involve higher manufacturing expenses and require specialized maintenance, leading to increased long-term costs. Evaluating total cost of ownership reveals leaf springs as cost-effective for standard heavy-duty use, whereas push rod systems suit performance-driven vehicles with dedicated maintenance resources.

Choosing the Right Suspension for Your Vehicle

Leaf springs offer durability and load-bearing strength ideal for heavy-duty trucks and off-road vehicles, providing a simple and cost-effective suspension solution. Push rod suspensions deliver superior handling and responsiveness commonly found in high-performance and sports cars due to their ability to maintain precise wheel control under dynamic conditions. Selecting the right suspension depends on vehicle purpose, with leaf springs favoring rugged utility and push rods excelling in performance-oriented driving scenarios.

Leaf spring Infographic

libterm.com

libterm.com