A Universal Testing Machine (UTM) is essential for evaluating the mechanical properties of materials, including tensile, compression, and bending tests. It provides accurate data on strength, elasticity, and deformation, helping engineers ensure product quality and safety. Discover how a UTM can enhance Your material testing processes by exploring the rest of this article.

Table of Comparison

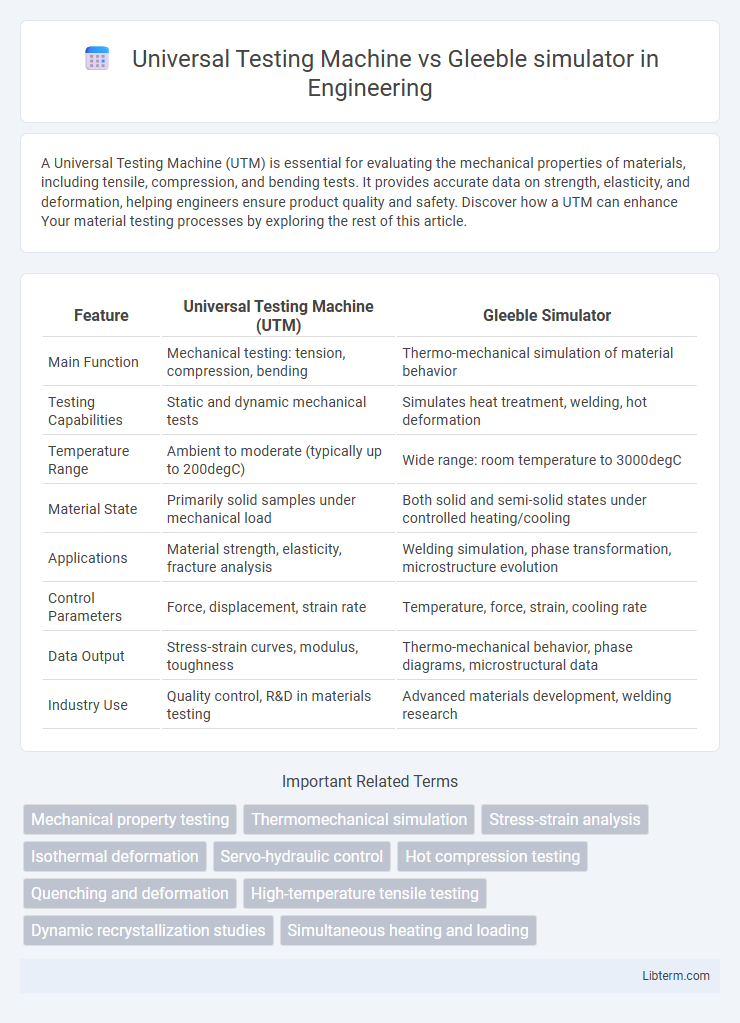

| Feature | Universal Testing Machine (UTM) | Gleeble Simulator |

|---|---|---|

| Main Function | Mechanical testing: tension, compression, bending | Thermo-mechanical simulation of material behavior |

| Testing Capabilities | Static and dynamic mechanical tests | Simulates heat treatment, welding, hot deformation |

| Temperature Range | Ambient to moderate (typically up to 200degC) | Wide range: room temperature to 3000degC |

| Material State | Primarily solid samples under mechanical load | Both solid and semi-solid states under controlled heating/cooling |

| Applications | Material strength, elasticity, fracture analysis | Welding simulation, phase transformation, microstructure evolution |

| Control Parameters | Force, displacement, strain rate | Temperature, force, strain, cooling rate |

| Data Output | Stress-strain curves, modulus, toughness | Thermo-mechanical behavior, phase diagrams, microstructural data |

| Industry Use | Quality control, R&D in materials testing | Advanced materials development, welding research |

Introduction to Universal Testing Machines and Gleeble Simulators

Universal Testing Machines (UTMs) are essential devices in material science for evaluating mechanical properties such as tensile strength, compressive strength, and elongation of metals, polymers, and composites under controlled loading conditions. Gleeble Simulators provide advanced thermal-mechanical testing by replicating real-world process conditions including rapid heating, cooling, and deformation, enabling the study of microstructural evolution and phase transformations. While UTMs primarily focus on static mechanical property measurement, Gleeble machines integrate precise thermal cycles with mechanical stress, offering comprehensive insights for materials development and process optimization.

Core Principles of Operation

The Universal Testing Machine (UTM) operates by applying controlled tensile, compressive, or bending forces to materials and measuring their response to determine mechanical properties such as strength, ductility, and elasticity. The Gleeble simulator uses rapid heating and controlled deformation to mimic thermal-mechanical processes, enabling the study of microstructural evolution under high-strain-rate conditions. Both devices are essential in materials science but differ fundamentally: the UTM focuses on static or quasi-static mechanical testing, while the Gleeble emphasizes dynamic metallurgical simulations.

Key Applications in Material Testing

Universal Testing Machines excel in tensile, compression, and bending tests, providing precise mechanical property data such as tensile strength and elongation for metals, plastics, and composites. Gleeble simulators specialize in thermomechanical simulation, replicating real-world forging, welding, and heat treatment conditions to study phase transformations and microstructural evolution. These distinct applications make Universal Testing Machines ideal for standard mechanical characterization, while Gleeble systems are crucial for advanced materials research and process development.

Sample Preparation and Specimen Size

Sample preparation for Universal Testing Machines typically involves standard-sized specimens such as ASTM or ISO tensile bars, requiring precise machining and strict dimensional tolerances to ensure uniform stress distribution. In contrast, Gleeble simulators accommodate smaller, machined specimens or tailor-made sample geometries that replicate localized thermal-mechanical processing conditions, often allowing more flexibility in size and shape. Specimen size in Universal Testing Machines is generally larger and standardized for mechanical property evaluation, while Gleeble specimens are smaller, optimized for rapid heating, cooling, and deformation cycles to simulate welding or forming processes accurately.

Testing Capabilities: Static vs. Dynamic Analysis

Universal Testing Machines excel in static testing capabilities, providing precise measurements of material properties such as tensile strength, compression, and elongation under controlled, steady loading conditions. In contrast, Gleeble simulators specialize in dynamic analysis by replicating rapid thermal and mechanical conditions to study real-time microstructural changes and phase transformations during heating, cooling, and deformation. The Universal Testing Machine is ideal for standardized material property assessments, while the Gleeble offers advanced simulation of thermomechanical processes for research and development in materials science.

Temperature and Environmental Control Features

Universal Testing Machines (UTMs) primarily focus on mechanical testing under controlled load and displacement conditions, offering limited temperature control typically ranging up to 1000degC with external heaters or environmental chambers. Gleeble simulators provide advanced temperature and environmental controls, capable of rapid thermal cycling between -200degC and 1500degC with precise control over heating rates and dwell times, simulating diverse thermal and mechanical processing environments. Gleeble systems also offer controlled atmosphere options such as vacuum, inert gas, or reactive gases, enabling detailed microstructural studies under realistic industrial conditions not possible in standard UTMs.

Data Accuracy and Measurement Precision

Universal Testing Machines deliver high data accuracy in tensile, compression, and flexural testing by employing precise load cells and extensometers for standardized material evaluation. Gleeble simulators offer superior measurement precision in dynamic thermal-mechanical simulations, capturing rapid microstructural changes with advanced real-time data acquisition systems. Both systems excel in different testing environments, with Universal Testing Machines providing consistent, repeatable mechanical property data and Gleeble simulators enabling detailed control over thermal cycles and deformation rates for metallurgical research.

Flexibility and Adaptability for Research

Universal Testing Machines (UTMs) offer exceptional flexibility by accommodating a wide range of materials and testing methods, including tensile, compression, and bending tests, making them ideal for diverse research applications. Gleeble simulators excel in adaptability by replicating complex thermal and mechanical conditions, enabling precise simulation of real-world processes such as welding, forming, and heat treatment. Researchers benefit from UTMs' broad testing capabilities while relying on Gleeble systems for dynamic, process-specific experimentation requiring controlled temperature and deformation conditions.

Cost, Maintenance, and Resource Requirements

The Universal Testing Machine generally has lower initial costs and simpler maintenance requirements compared to the Gleeble simulator, which involves higher expenses due to its advanced thermal-mechanical testing capabilities. Maintenance for a Universal Testing Machine typically requires routine calibration and minimal part replacement, whereas the Gleeble simulator demands specialized support and more frequent servicing due to its complex thermal components. Resource-wise, the Universal Testing Machine operates with basic power and space needs, while the Gleeble simulator requires significant infrastructure, including advanced cooling systems and precise environmental controls to simulate high-temperature conditions accurately.

Choosing the Right Equipment for Your Material Testing Needs

Selecting the right equipment for material testing hinges on the specific properties and conditions being evaluated; Universal Testing Machines (UTMs) excel in tensile, compression, and bending tests, providing precise load and deformation data for metals, polymers, and composites. Gleeble simulators offer advanced thermo-mechanical simulation capabilities, replicating real-world thermal cycles and mechanical stresses to study phase transformations and material behavior at high temperatures. For applications requiring standard mechanical property measurement, UTMs are ideal, whereas Gleeble systems are essential for research involving complex thermal-mechanical processes and microstructural evolution.

Universal Testing Machine Infographic

libterm.com

libterm.com