The rib cage protects vital organs such as the heart and lungs while providing structural support to the upper body. Each rib curves from the spine toward the sternum, allowing flexibility and movement essential for breathing. Explore the rest of the article to understand how your ribs contribute to both protection and respiratory function.

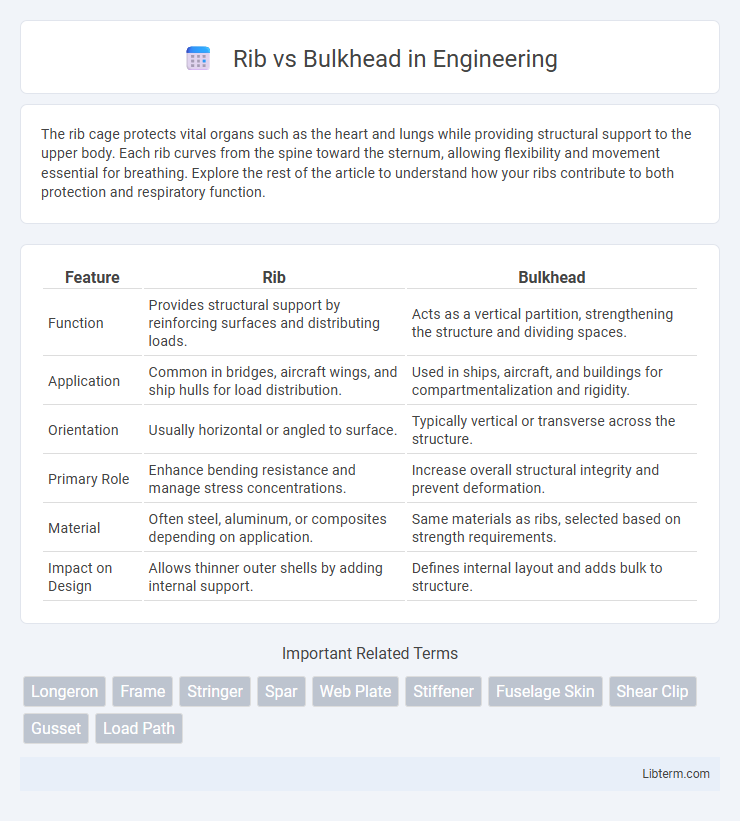

Table of Comparison

| Feature | Rib | Bulkhead |

|---|---|---|

| Function | Provides structural support by reinforcing surfaces and distributing loads. | Acts as a vertical partition, strengthening the structure and dividing spaces. |

| Application | Common in bridges, aircraft wings, and ship hulls for load distribution. | Used in ships, aircraft, and buildings for compartmentalization and rigidity. |

| Orientation | Usually horizontal or angled to surface. | Typically vertical or transverse across the structure. |

| Primary Role | Enhance bending resistance and manage stress concentrations. | Increase overall structural integrity and prevent deformation. |

| Material | Often steel, aluminum, or composites depending on application. | Same materials as ribs, selected based on strength requirements. |

| Impact on Design | Allows thinner outer shells by adding internal support. | Defines internal layout and adds bulk to structure. |

Introduction to Ribs and Bulkheads

Ribs and bulkheads are essential structural components in shipbuilding and aerospace engineering, providing strength and shape to the framework. Ribs are longitudinal elements that reinforce the hull or fuselage, distributing loads evenly and maintaining aerodynamic or hydrodynamic integrity. Bulkheads are vertical partitions dividing the interior into compartments, enhancing structural rigidity and safety by preventing the spread of fire or flooding.

Defining Ribs: Structure and Function

Ribs are curved structural components integral to a vessel's framework, designed to provide transverse support and maintain the hull's shape under external pressure. Their primary function is to distribute stresses evenly across the hull, preventing deformation and enhancing the ship's overall structural integrity. Unlike bulkheads, ribs run longitudinally or transversely along the hull's contour, reinforcing the vessel's shell rather than compartmentalizing its interior.

Bulkheads: Roles and Importance

Bulkheads serve as crucial structural components in shipbuilding and aviation, providing compartmentalization to enhance safety by preventing the spread of fire and flooding. Engineered for strength and rigidity, bulkheads contribute significantly to the overall integrity and durability of vessels and aircraft. Their role extends to supporting mechanical systems and isolating different sections, ensuring operational efficiency and compliance with safety regulations.

Key Differences Between Ribs and Bulkheads

Ribs and bulkheads serve distinct structural roles in shipbuilding: ribs provide transverse support to the hull, enhancing the vessel's overall strength and resistance to bending, while bulkheads are vertical partitions that divide the ship into watertight compartments, preventing flooding from spreading. Ribs are typically curved frames running from the keel to the deck, forming the skeleton, whereas bulkheads are flat or slightly curved walls extending from the bottom to the deck, crucial for compartmentalization and safety. The key difference lies in their primary functions--ribs reinforce the hull's shape and durability, bulkheads ensure compartmental integrity and contribute to the vessel's stability during damage or flooding.

Applications of Ribs in Engineering

Ribs in engineering are structural elements designed to enhance the strength and stiffness of components without significantly increasing weight, commonly applied in aerospace, automotive, and marine industries. They provide support to thin or flat panels, improving load distribution and resistance to bending or buckling, which is critical in aircraft wing design and vehicle chassis. Ribs are preferred over bulkheads in applications requiring localized reinforcement and flexibility, facilitating efficient material use and vibration reduction in lightweight structures.

Uses of Bulkheads in Construction

Bulkheads are crucial structural elements used to divide spaces within vessels, buildings, and underground constructions, providing both support and compartmentalization. In building construction, bulkheads often conceal HVAC systems, electrical wiring, and plumbing, enhancing aesthetics and functionality without compromising structural integrity. Unlike ribs that primarily offer reinforcement, bulkheads serve as partition walls that improve fire resistance, noise control, and spatial organization.

Material Selection for Ribs and Bulkheads

Material selection for ribs and bulkheads significantly impacts structural integrity and weight optimization in aerospace and marine engineering. Aluminum alloys, known for high strength-to-weight ratios and corrosion resistance, are preferred for both ribs and bulkheads in aircraft to ensure durability without adding excessive weight. Composite materials like carbon fiber reinforced polymers are increasingly used for bulkheads to enhance stiffness and reduce mass, while ribs often utilize titanium or advanced aluminum alloys to balance performance and manufacturing costs.

Design Considerations: Rib vs Bulkhead

Ribs offer structural reinforcement by distributing loads along the surface, making them ideal for increasing stiffness without significant weight gain. Bulkheads provide robust compartmentalization and can withstand higher localized stress, enhancing overall structural integrity and crashworthiness. Design considerations must balance weight, load distribution, manufacturing complexity, and functional requirements to determine the optimal use of ribs or bulkheads in engineering applications.

Structural Integrity: Performance Comparison

Ribs enhance structural integrity by distributing loads evenly across a vessel's hull, providing superior resistance to bending and torsional forces compared to bulkheads, which primarily serve as vertical partitions that contribute to compartmentalization and localized stiffness. The integration of ribs is critical in reinforcing longitudinal strength and improving overall hull durability, especially in dynamic marine environments. Bulkheads complement ribs by increasing transverse rigidity and maintaining the vessel's shape under pressure but are less effective alone in resisting complex stress patterns.

Conclusion: Choosing Between Rib and Bulkhead

Selecting between rib and bulkhead construction depends on the specific structural requirements and design goals of the project. Rib construction offers lightweight support with enhanced flexibility for curved surfaces, making it ideal for aircraft and boat hulls. Bulkhead construction provides superior strength and compartmentalization, essential for maintaining structural integrity in ships, submarines, and complex architectural designs.

Rib Infographic

libterm.com

libterm.com