Modbus and OPC UA are two widely used industrial communication protocols designed to facilitate data exchange between devices and systems on the factory floor. Modbus is known for its simplicity and compatibility with legacy equipment, while OPC UA offers advanced features such as platform independence, security, and scalability for modern industrial automation. Discover how these protocols can enhance Your industrial network by exploring their key differences and applications in the rest of this article.

Table of Comparison

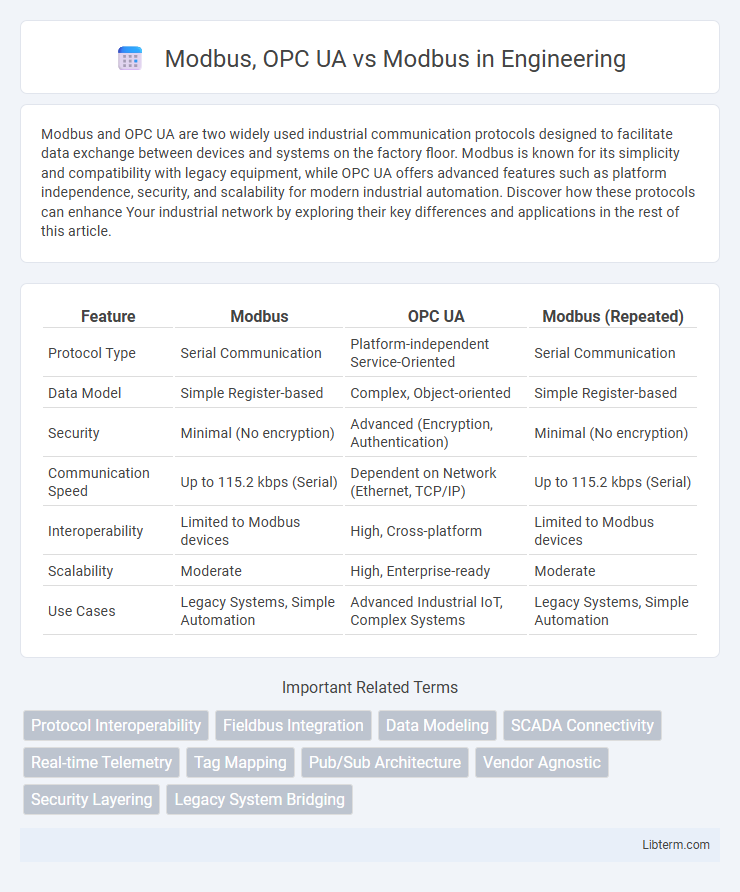

| Feature | Modbus | OPC UA | Modbus (Repeated) |

|---|---|---|---|

| Protocol Type | Serial Communication | Platform-independent Service-Oriented | Serial Communication |

| Data Model | Simple Register-based | Complex, Object-oriented | Simple Register-based |

| Security | Minimal (No encryption) | Advanced (Encryption, Authentication) | Minimal (No encryption) |

| Communication Speed | Up to 115.2 kbps (Serial) | Dependent on Network (Ethernet, TCP/IP) | Up to 115.2 kbps (Serial) |

| Interoperability | Limited to Modbus devices | High, Cross-platform | Limited to Modbus devices |

| Scalability | Moderate | High, Enterprise-ready | Moderate |

| Use Cases | Legacy Systems, Simple Automation | Advanced Industrial IoT, Complex Systems | Legacy Systems, Simple Automation |

Introduction to Modbus

Modbus is a widely adopted communication protocol in industrial automation, designed for connecting electronic devices and enabling data exchange between control systems and sensors. Unlike OPC UA, which offers advanced features like platform independence and enhanced security, Modbus remains popular due to its simplicity, reliability, and ease of implementation in real-time monitoring. Understanding Modbus fundamentals is essential for integrating legacy systems and ensuring compatibility with modern industrial networks.

Overview of OPC UA

OPC UA (Open Platform Communications Unified Architecture) provides advanced interoperability, security, and platform independence compared to the traditional Modbus protocol, which is simpler and primarily designed for serial communication in industrial environments. Unlike Modbus, OPC UA supports complex data modeling, reliable encryption, and native web services, enabling seamless integration across diverse industrial systems and cloud platforms. OPC UA's architecture facilitates scalable, secure, and standardized data exchange, making it ideal for modern industrial automation and Industry 4.0 applications.

Key Features of Modbus

Modbus is a communication protocol primarily designed for industrial automation systems, known for its simplicity, ease of implementation, and wide adoption. Key features of Modbus include its master-slave architecture, support for serial and TCP/IP networks, and standardized function codes for reading and writing data to registers and coils. Unlike OPC UA, which offers complex data modeling, security enhancements, and platform-independent interoperability, Modbus focuses on straightforward data exchange and real-time control in resource-constrained environments.

Key Features of OPC UA

OPC UA offers advanced security features like encryption, authentication, and auditing, surpassing Modbus' basic communication protocol. Unlike Modbus' simple master-slave architecture, OPC UA supports complex data models, interoperability, and platform independence, enabling seamless integration across diverse industrial systems. OPC UA's event-driven communication and built-in service-oriented architecture provide enhanced scalability and real-time data access critical for modern automation and Industry 4.0 applications.

Communication Protocol Differences

Modbus operates on a simple, master-slave communication model using serial or TCP/IP protocols, providing straightforward data transmission with limited security features. OPC UA employs a client-server architecture supporting complex data models, enhanced security with encryption and authentication, and platform independence across various communication protocols. The primary communication protocol difference lies in Modbus's simplicity and raw data handling versus OPC UA's robust, secure, and semantic-rich data exchange.

Data Modeling and Structure Comparison

Modbus operates as a simple, register-based communication protocol with limited data modeling capabilities, primarily handling raw data values in a flat structure. OPC UA offers a comprehensive and flexible data modeling framework, supporting complex hierarchical structures, rich metadata, and semantic information through its address space and object-oriented design. The structured data representation and built-in discovery services of OPC UA enable enhanced interoperability and contextual understanding compared to Modbus's straightforward, value-centric approach.

Security: Modbus vs OPC UA

Modbus lacks native security features such as encryption and authentication, making it vulnerable to unauthorized access and data tampering in industrial networks. OPC UA provides robust built-in security mechanisms including message encryption, user authentication, and role-based access control to safeguard critical data exchanges. The advanced security framework of OPC UA supports compliance with modern cybersecurity standards, positioning it as the preferred protocol for secure industrial communication.

Industrial Use Cases

Modbus remains widely used in industrial automation for its simplicity and legacy device compatibility, enabling efficient communication between programmable logic controllers (PLCs) and sensors. OPC UA offers enhanced security, platform independence, and semantic data modeling, making it ideal for complex industrial IoT applications, predictive maintenance, and cross-vendor interoperability. Industries increasingly adopt OPC UA alongside or as a replacement for Modbus to support scalable, secure, and standardized data exchange in advanced manufacturing environments.

Integration and Interoperability

Modbus offers straightforward integration with legacy industrial devices due to its simplicity and widespread adoption, but it lacks native support for complex data models and secure communication. OPC UA provides superior interoperability by enabling seamless data exchange across diverse platforms with standardized information modeling and built-in security protocols. The advanced architecture of OPC UA facilitates integration in modern industrial automation systems, making it the preferred choice for scalable and secure cross-vendor connectivity.

Future Trends: Modbus and OPC UA

Modbus remains widely used for its simplicity and compatibility in industrial automation, but OPC UA is gaining momentum due to its enhanced security, scalability, and interoperability across modern IIoT systems. Future trends indicate OPC UA will increasingly integrate with existing Modbus networks through protocol converters, enabling seamless data exchange and advanced analytics. The convergence of OPC UA's information modeling with Modbus's device-level accessibility supports a transition toward smarter, more connected industrial environments.

Modbus, OPC UA Infographic

libterm.com

libterm.com