Friction drive systems utilize the contact between rotating components to transfer power efficiently without gears, reducing noise and mechanical complexity. These drives are commonly found in applications ranging from bicycles to industrial machinery, where smooth and adjustable speed control is essential. Explore the rest of the article to discover how friction drive technology can enhance your mechanical projects.

Table of Comparison

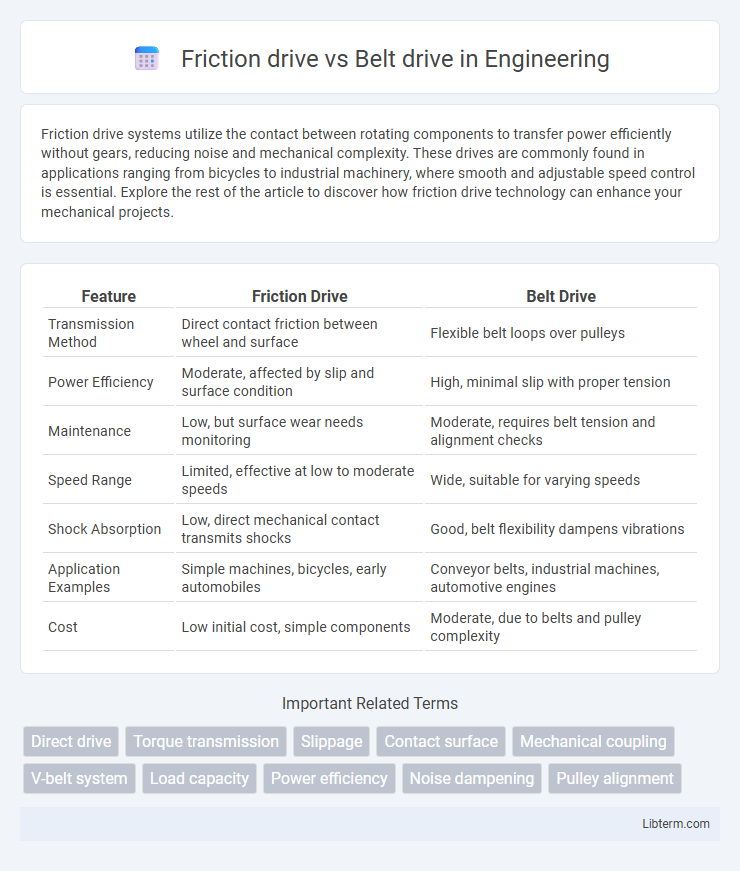

| Feature | Friction Drive | Belt Drive |

|---|---|---|

| Transmission Method | Direct contact friction between wheel and surface | Flexible belt loops over pulleys |

| Power Efficiency | Moderate, affected by slip and surface condition | High, minimal slip with proper tension |

| Maintenance | Low, but surface wear needs monitoring | Moderate, requires belt tension and alignment checks |

| Speed Range | Limited, effective at low to moderate speeds | Wide, suitable for varying speeds |

| Shock Absorption | Low, direct mechanical contact transmits shocks | Good, belt flexibility dampens vibrations |

| Application Examples | Simple machines, bicycles, early automobiles | Conveyor belts, industrial machines, automotive engines |

| Cost | Low initial cost, simple components | Moderate, due to belts and pulley complexity |

Introduction to Friction Drive and Belt Drive

Friction drives transmit power through the direct contact of rotating surfaces, relying on frictional force to transfer torque without the need for gears or chains, making them simple and quiet. Belt drives use flexible belts looping over pulleys to transmit rotational motion, offering efficient power transfer with the ability to accommodate misalignment and absorb shocks. Both systems are widely applied in machinery, with friction drives excelling in low-speed applications and belt drives preferred for higher speed and varying load demands.

How Friction Drive Works

Friction drive operates by transmitting power through direct contact between a driving wheel and a driven wheel, relying on frictional force to transfer torque efficiently without the need for belts or chains. The driving wheel's surface presses against the driven wheel, and the frictional grip allows for smooth motion and variable speed control by adjusting the contact pressure or position. This mechanism reduces slippage and maintenance compared to belt drives, making friction drives suitable for applications requiring precise speed variation and minimal mechanical complexity.

How Belt Drive Works

Belt drives operate by transmitting power through a flexible belt looped over pulleys attached to rotating shafts, relying on friction between the belt and pulley surfaces to transfer motion efficiently. The belt, typically made of rubber or synthetic materials, maintains tension to prevent slipping and ensures smooth, continuous power transmission in machinery such as bicycles, conveyors, and automotive engines. Unlike friction drives, which depend on direct contact between smooth wheels, belt drives offer advantages in shock absorption, alignment flexibility, and ease of maintenance.

Key Differences Between Friction and Belt Drive

Friction drive transmits power through direct contact between two rotating surfaces, offering simple construction and smooth speed variation, whereas belt drive uses a flexible belt looped over pulleys for power transmission, providing efficiency and capability for longer distance power transfer. Friction drives typically have lower torque capacity and are more susceptible to slippage under load compared to belt drives, which maintain grip through tension and material properties. Belt drives require regular maintenance for belt tension and wear, while friction drives demand precise surface contact and may experience wear faster due to surface friction.

Efficiency Comparison: Friction vs Belt Drive

Friction drives typically exhibit lower efficiency than belt drives due to energy losses from slippage and surface friction, often ranging between 85% to 90%, whereas belt drives can achieve efficiencies exceeding 95% under optimal tension and alignment. Belt drives also maintain consistent power transmission with minimal heat generation, reducing wear and energy loss compared to the variable contact pressure in friction drives. The choice between friction and belt drives impacts mechanical performance, with belt drives favored in high-load applications where energy efficiency is critical.

Maintenance Requirements of Each System

Friction drive systems require frequent inspection and replacement of friction materials due to wear from constant contact, often necessitating careful adjustment to maintain optimal pressure and prevent slippage. Belt drive systems demand regular tension checks and periodic belt replacement to avoid stretching and cracking, along with pulley alignment to reduce wear and increase belt lifespan. Both systems benefit from routine lubrication of associated components, but belt drives generally offer lower maintenance frequency compared to friction drives because they experience less direct material wear.

Durability and Longevity Factors

Friction drives generally offer lower durability compared to belt drives due to direct surface contact causing faster wear and potential slippage under heavy loads. Belt drives provide enhanced longevity as they absorb shock and vibrations better, reducing stress on components and extending operational life. Material quality, maintenance frequency, and load conditions significantly influence the lifespan of both friction and belt drive systems.

Cost Considerations

Friction drive systems generally offer lower initial costs and simpler maintenance compared to belt drives, making them suitable for budget-sensitive applications. Belt drives often require higher upfront investment due to the need for quality belts, pulleys, and tensioning mechanisms but provide longer service life and reduced slippage, potentially lowering long-term expenses. Evaluating total cost of ownership, including replacement parts and operational efficiency, is essential when choosing between friction drive and belt drive systems.

Applications and Use Cases

Friction drive systems are commonly used in low-torque applications such as conveyors, printing presses, and light machinery due to their simplicity and smooth speed variation. Belt drives excel in transmitting higher power over longer distances, frequently found in automotive engines, industrial machinery, and agricultural equipment where durability and reliability are critical. Both systems serve distinct roles, with friction drives favored for precise control and belt drives preferred for heavy-duty power transmission.

Which Drive System is Best for Your Needs?

Friction drive offers smoother acceleration and quieter operation, making it ideal for light-duty applications and precise speed control. Belt drive systems provide higher torque capacity, durability, and better handling of heavy loads, suited for industrial or high-power machinery. Choosing the best drive system depends on factors like load requirements, maintenance preferences, noise tolerance, and operational environment.

Friction drive Infographic

libterm.com

libterm.com