Seam weld is a continuous welding process that joins two metal surfaces along a single, extended line, providing a strong and airtight seal ideal for pipes, tanks, and pressure vessels. This technique enhances structural integrity by preventing leaks and ensuring durability under stress. Explore the rest of the article to understand how seam weld can improve the quality and performance of your metal fabrication projects.

Table of Comparison

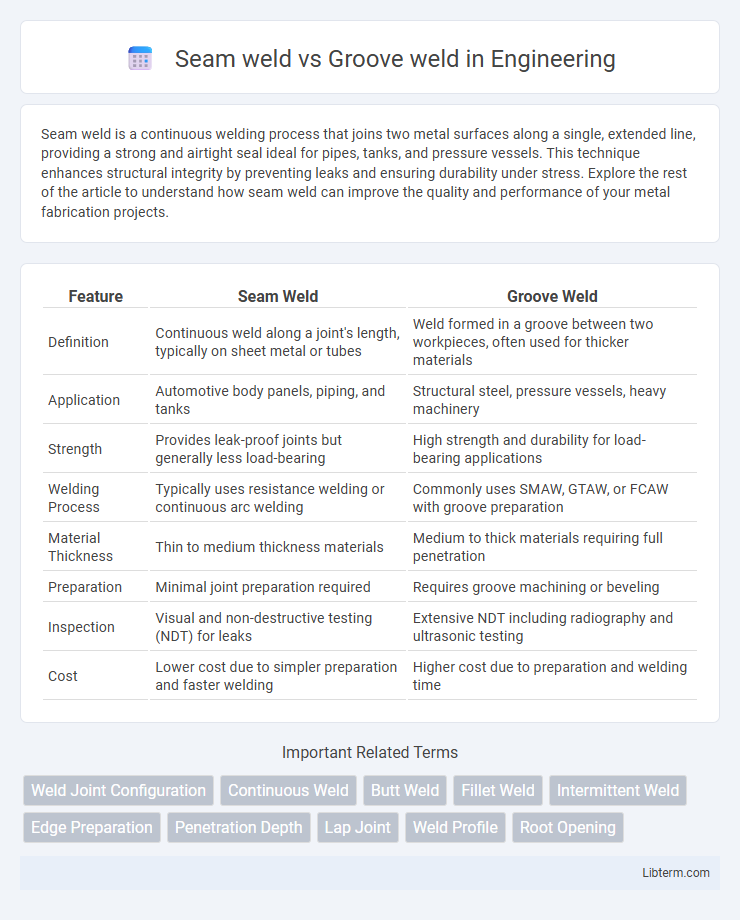

| Feature | Seam Weld | Groove Weld |

|---|---|---|

| Definition | Continuous weld along a joint's length, typically on sheet metal or tubes | Weld formed in a groove between two workpieces, often used for thicker materials |

| Application | Automotive body panels, piping, and tanks | Structural steel, pressure vessels, heavy machinery |

| Strength | Provides leak-proof joints but generally less load-bearing | High strength and durability for load-bearing applications |

| Welding Process | Typically uses resistance welding or continuous arc welding | Commonly uses SMAW, GTAW, or FCAW with groove preparation |

| Material Thickness | Thin to medium thickness materials | Medium to thick materials requiring full penetration |

| Preparation | Minimal joint preparation required | Requires groove machining or beveling |

| Inspection | Visual and non-destructive testing (NDT) for leaks | Extensive NDT including radiography and ultrasonic testing |

| Cost | Lower cost due to simpler preparation and faster welding | Higher cost due to preparation and welding time |

Introduction to Seam Welds and Groove Welds

Seam welds are continuous welds formed along the length of two overlapping metal surfaces, commonly used in manufacturing to create airtight or watertight joints in sheet metal applications. Groove welds involve welding within a prepared groove between two pieces of metal, designed to provide deep penetration and high strength, typically used in structural steel and pipe welding. Understanding the distinct applications and weld profiles of seam welds versus groove welds is essential for selecting the appropriate welding technique based on joint strength, material thickness, and intended use.

Understanding Weld Joint Types

Seam welds create long, continuous joints by fusing overlapping edges, commonly used for leak-proof applications such as tanks and pipes. Groove welds involve welding within a prepared groove between two members, offering strong joint penetration essential for structural components. Each weld type serves distinct purposes based on joint design, load requirements, and accessibility during fabrication.

Definition and Characteristics of Seam Weld

Seam weld is a continuous weld made along a joint where two metal surfaces meet edge to edge, commonly used in sheet metal fabrication and pipe manufacturing to ensure leak-proof and durable seals. It is characterized by a consistent, tight weld bead that runs the entire length of the joint, providing strength and resistance to stress, corrosion, and fatigue. Unlike groove welds, which join surfaces with a prepared groove and often require filler material, seam welds primarily focus on joining thin materials with minimal preparation and a smooth finish.

Definition and Characteristics of Groove Weld

Groove weld is a type of weld used to join two workpieces along a prepared groove or joint, characterized by its ability to penetrate deeply and provide strong, continuous fusion across the joint. Unlike seam welds, which are typically applied along a continuous lap joint for sealing or joining thin materials, groove welds accommodate various joint designs such as butt, V, U, J, or square grooves. This weld type is essential for structural applications requiring high strength and reliability, often performed with techniques like shielded metal arc welding (SMAW), gas metal arc welding (GMAW), or gas tungsten arc welding (GTAW).

Seam Weld vs Groove Weld: Key Differences

Seam welds are continuous welds made along a joint's length, ideal for joining sheet metals in applications requiring airtight or watertight seals. Groove welds involve filling a groove between two metal pieces, providing strong structural joints commonly used in thicker materials and heavy-duty constructions. The key difference lies in their application and joint preparation: seam welds prioritize continuous sealing, while groove welds focus on strength and penetration across joint faces.

Applications of Seam Welds

Seam welds are commonly used in applications requiring continuous, airtight, and watertight joints such as pipe manufacturing, automotive fuel tanks, and metal roofing systems. Their design allows for automated welding processes, ensuring consistent strength and corrosion resistance in long, linear seams. Seam welds excel in industries where durability and leak prevention are critical, differentiating them from groove welds typically applied in structural or thicker material joints.

Applications of Groove Welds

Groove welds are extensively used in structural steel fabrication, shipbuilding, and pipeline construction due to their ability to provide deep penetration and strong joints in thick materials. They are ideal for applications requiring high-strength connections, such as bridges, heavy machinery, and pressure vessels. Groove welds accommodate various joint designs, including butt, T-joints, and corner joints, making them versatile for complex engineering projects.

Advantages and Limitations of Seam Welds

Seam welds offer continuous, gas-tight joints ideal for applications requiring airtight or watertight seals, such as in automotive fuel tanks or metal containers, providing consistent strength along the seam. Their automation capability reduces labor costs and improves productivity, but seam welds may have limitations in handling high-stress conditions compared to groove welds, which provide deeper penetration and better load distribution. Material thickness and joint design constraints also limit seam weld applications, making groove welds preferable for heavy structural components requiring greater weld strength and toughness.

Advantages and Limitations of Groove Welds

Groove welds offer superior strength and deep penetration, making them ideal for heavy structural applications that require load-bearing capacity and resistance to fatigue. They can accommodate varying joint designs such as butt, T-joints, and corner joints, providing versatility in fabrication processes. However, groove welds often require more preparation, skilled labor, and higher welding time compared to seam welds, which can increase overall production costs and complexity.

Choosing the Right Weld Type for Your Project

Seam welds provide continuous, leak-proof joints ideal for thin metals and sheet applications, ensuring strength and corrosion resistance. Groove welds offer deeper penetration suitable for thicker materials and critical structural components requiring maximum load-bearing capacity. Selecting the right weld type depends on material thickness, joint design, and load requirements to balance strength, durability, and fabrication efficiency.

Seam weld Infographic

libterm.com

libterm.com