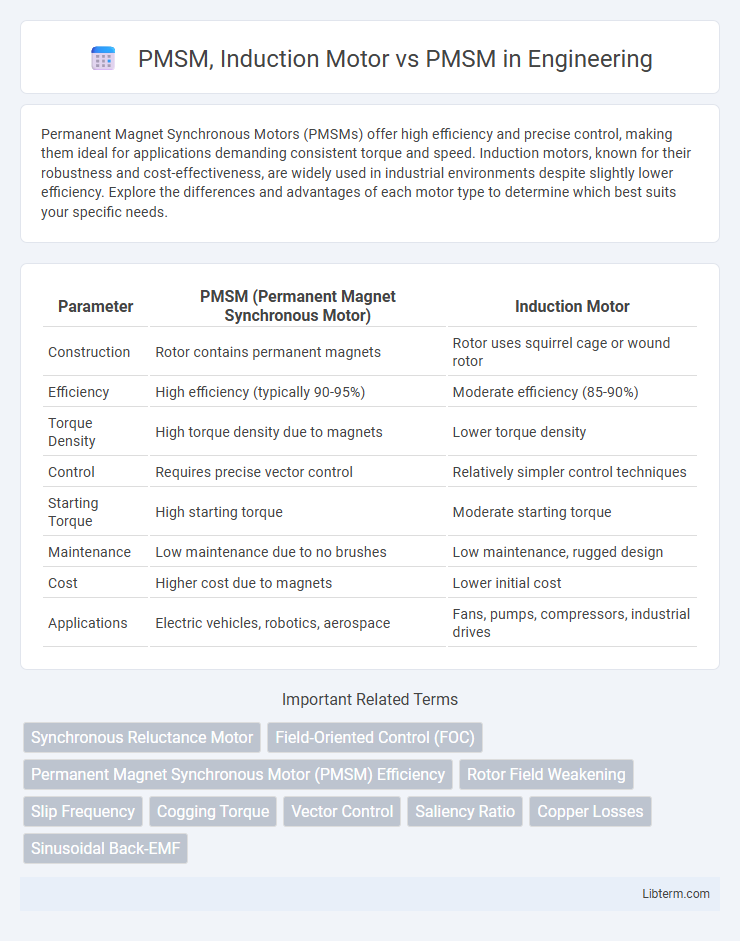

Permanent Magnet Synchronous Motors (PMSMs) offer high efficiency and precise control, making them ideal for applications demanding consistent torque and speed. Induction motors, known for their robustness and cost-effectiveness, are widely used in industrial environments despite slightly lower efficiency. Explore the differences and advantages of each motor type to determine which best suits your specific needs.

Table of Comparison

| Parameter | PMSM (Permanent Magnet Synchronous Motor) | Induction Motor |

|---|---|---|

| Construction | Rotor contains permanent magnets | Rotor uses squirrel cage or wound rotor |

| Efficiency | High efficiency (typically 90-95%) | Moderate efficiency (85-90%) |

| Torque Density | High torque density due to magnets | Lower torque density |

| Control | Requires precise vector control | Relatively simpler control techniques |

| Starting Torque | High starting torque | Moderate starting torque |

| Maintenance | Low maintenance due to no brushes | Low maintenance, rugged design |

| Cost | Higher cost due to magnets | Lower initial cost |

| Applications | Electric vehicles, robotics, aerospace | Fans, pumps, compressors, industrial drives |

Introduction to PMSM and Induction Motors

Permanent Magnet Synchronous Motors (PMSMs) utilize permanent magnets embedded in the rotor, offering high efficiency and precise control with reduced energy losses compared to induction motors. Induction motors operate by inducing current in the rotor windings through electromagnetic induction, resulting in a robust and cost-effective design but lower efficiency. PMSMs are preferred in applications requiring high torque density and precise speed control, while induction motors dominate in heavy-duty industrial scenarios due to their simplicity and durability.

Fundamental Working Principles of PMSM

Permanent Magnet Synchronous Motors (PMSMs) operate by utilizing permanent magnets embedded in the rotor to create a constant magnetic field, while the stator windings are energized with a three-phase AC current producing a rotating magnetic field that synchronizes with the rotor's speed. Unlike induction motors which rely on electromagnetic induction to generate rotor currents and torque, PMSMs deliver higher efficiency, precise control, and better torque density due to the absence of rotor current losses. The fundamental working principle of PMSMs centers on synchronous operation where the rotor magnetic field, produced by permanent magnets, rotates in exact harmony with the stator magnetic field.

Key Features of Induction Motors

Induction motors operate using electromagnetic induction to produce torque, featuring a robust and simple squirrel-cage rotor design that enhances durability and reduces maintenance. They offer excellent performance in variable speed and load conditions, benefiting from their rugged construction and cost-effective manufacturing. High starting torque, reliability in harsh environments, and ease of control through well-established methods make induction motors a preferred choice for industrial applications.

Comparative Analysis: PMSM vs Induction Motors

Permanent Magnet Synchronous Motors (PMSMs) offer higher efficiency and power density compared to Induction Motors due to their use of rare-earth magnets which reduce rotor losses and enhance performance. PMSMs provide superior torque control and faster dynamic response, making them ideal for applications requiring precise motion control, whereas Induction Motors are favored for their robustness, lower initial cost, and simpler construction. The comparative analysis highlights PMSMs as the preferred choice in electric vehicles and robotics for energy efficiency and compact design, while Induction Motors remain dominant in industrial settings where durability and cost-effectiveness are prioritized.

Efficiency and Performance Differences

Permanent Magnet Synchronous Motors (PMSM) exhibit higher efficiency and superior performance compared to Induction Motors due to their use of permanent magnets that eliminate rotor copper losses. PMSMs deliver better torque density, faster dynamic response, and lower heat generation, making them ideal for precision applications and energy-saving systems. Induction Motors, while robust and cost-effective, typically have lower efficiency because of rotor current losses and slower response times.

Application Areas: Who Uses What and Why?

Permanent Magnet Synchronous Motors (PMSMs) are favored in applications requiring high efficiency, precise control, and compact size, such as electric vehicles, robotics, and aerospace systems. Induction motors dominate industrial settings, including pumps, conveyors, and HVAC systems, due to their robustness, cost-effectiveness, and simpler control methods. The preference for PMSMs or induction motors largely depends on performance needs, efficiency targets, and budget constraints within specific industries.

Design and Construction Variations

PMSM (Permanent Magnet Synchronous Motor) features a rotor embedded with high-performance permanent magnets, eliminating the need for external excitation and enabling higher efficiency and power density. Induction motors rely on electromagnetic induction with a squirrel-cage rotor, resulting in simpler construction but lower efficiency compared to PMSMs. The design of PMSM involves precise magnet placement and rotor saliency to maximize torque production, whereas induction motors use laminated steel rotors and rely on slip for torque generation.

Cost Implications: Initial vs Long-Term

Permanent Magnet Synchronous Motors (PMSMs) typically have higher initial costs due to expensive rare-earth magnets and complex manufacturing processes. Induction motors, however, are generally more affordable upfront and widely used due to simpler construction and lower material costs. Over the long term, PMSMs offer greater energy efficiency and lower maintenance expenses, potentially offsetting the initial investment compared to the higher operational costs of induction motors.

Maintenance and Reliability Comparison

Permanent Magnet Synchronous Motors (PMSMs) offer higher efficiency and lower maintenance due to their brushless design and absence of rotor windings, reducing wear and the need for frequent servicing compared to induction motors. Induction motors require regular inspection of rotor bars and slip rings, leading to increased downtime and maintenance costs over the motor's lifespan. PMSMs provide superior reliability in applications demanding precise control and consistent performance, minimizing unexpected failures and extending operational life.

Future Trends in Electric Motor Technology

Permanent Magnet Synchronous Motors (PMSMs) offer higher efficiency, better power density, and superior torque control compared to Induction Motors, making them increasingly popular in electric vehicles and renewable energy applications. Future trends emphasize advancements in high-temperature rare-earth magnets, enhanced inverter technologies, and AI-driven predictive maintenance to further improve PMSM performance and reliability. As the demand for energy-efficient and compact electric drives grows, PMSMs are set to dominate next-generation motor designs due to their scalability and integration with smart grid systems.

PMSM, Induction Motor Infographic

libterm.com

libterm.com