Fatigue is a common condition characterized by persistent tiredness that affects your physical and mental performance. Understanding its causes, such as stress, lack of sleep, or underlying medical issues, is crucial for effective management. Explore the rest of this article to discover strategies to combat fatigue and improve your energy levels.

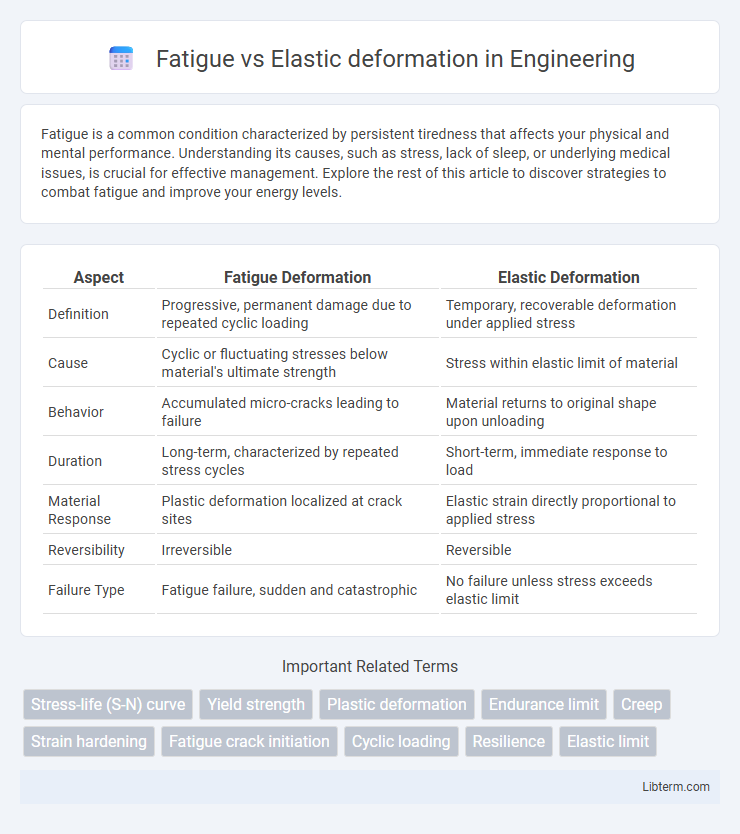

Table of Comparison

| Aspect | Fatigue Deformation | Elastic Deformation |

|---|---|---|

| Definition | Progressive, permanent damage due to repeated cyclic loading | Temporary, recoverable deformation under applied stress |

| Cause | Cyclic or fluctuating stresses below material's ultimate strength | Stress within elastic limit of material |

| Behavior | Accumulated micro-cracks leading to failure | Material returns to original shape upon unloading |

| Duration | Long-term, characterized by repeated stress cycles | Short-term, immediate response to load |

| Material Response | Plastic deformation localized at crack sites | Elastic strain directly proportional to applied stress |

| Reversibility | Irreversible | Reversible |

| Failure Type | Fatigue failure, sudden and catastrophic | No failure unless stress exceeds elastic limit |

Introduction to Fatigue and Elastic Deformation

Fatigue refers to the progressive and localized structural damage occurring when a material is subjected to cyclic loading, leading to crack initiation and eventual failure even below the material's ultimate tensile strength. Elastic deformation is the reversible change in shape or size of a material under applied stress, where the material returns to its original form once the load is removed, governed by Hooke's Law within the elastic limit. Understanding the distinctions between fatigue and elastic deformation is critical for predicting material lifespan and ensuring structural integrity in engineering applications.

Defining Fatigue in Materials Science

Fatigue in materials science refers to the progressive and localized structural damage that occurs when a material is subjected to cyclic loading, leading to the initiation and growth of cracks over time. This phenomenon differs from elastic deformation, which is a temporary and reversible change in shape when stress is applied within the elastic limit of the material. Fatigue failure can occur well below the material's ultimate tensile strength, making it critical to understand in engineering design to prevent unexpected fractures.

Understanding Elastic Deformation

Elastic deformation occurs when a material undergoes stress but returns to its original shape once the load is removed, characterized by reversible atomic bond stretching within the elastic limit. This deformation follows Hooke's Law, where stress is proportional to strain, and no permanent microscopic changes happen in the material's structure. Understanding elastic deformation is crucial for designing components that experience cyclic loading to prevent transition into plastic deformation or fatigue failure.

Key Differences Between Fatigue and Elastic Deformation

Fatigue refers to the progressive and localized structural damage occurring under cyclic loading, leading to material failure after repeated stress cycles below the ultimate tensile strength. Elastic deformation is the temporary and reversible shape change that occurs when a material is subjected to stress within its elastic limit, returning to its original form once the load is removed. Key differences include that fatigue involves irreversible damage accumulated over time causing cracks and eventual fracture, while elastic deformation does not produce permanent changes or damage to the material's microstructure.

Causes and Mechanisms of Fatigue

Fatigue occurs due to repetitive cyclic loading that induces microscopic cracks and progressive material damage, whereas elastic deformation is a reversible change in shape caused by stresses below the yield strength. Fatigue mechanisms involve crack initiation at stress concentrators such as surface defects or inclusions, crack propagation through the material, and eventual fracture. Elastic deformation involves atomic bond stretching within the elastic limit, allowing the material to return to its original shape once the load is removed.

How Elastic Deformation Occurs

Elastic deformation occurs when a material experiences stress within its elastic limit, causing atomic bonds to stretch without permanent displacement. This reversible deformation allows the material to return to its original shape once the applied load is removed. Elastic modulus and yield strength are key properties determining the extent of elastic deformation before transitioning to plastic deformation or fatigue failure.

Effects of Cyclic Loading vs. Instantaneous Stress

Fatigue involves the progressive and localized structural damage that occurs when a material is subjected to cyclic loading, causing microcracks to initiate and propagate over time, ultimately leading to failure below the material's ultimate tensile strength. Elastic deformation occurs instantaneously when a material experiences stress within its elastic limit, resulting in temporary shape change that fully recovers after load removal. Cyclic loading induces fatigue damage by repetitive stress fluctuations, whereas instantaneous stress causes elastic deformation as a reversible response without permanent damage.

Material Behavior Under Repeated vs. Temporary Loads

Fatigue refers to the progressive and localized structural damage that occurs when a material is subjected to repeated cyclic loading, leading to crack initiation and eventual failure even below the material's yield strength. Elastic deformation occurs when a material temporarily changes shape under an applied load but returns to its original form once the load is removed, indicating reversible behavior within the material's elastic limit. The key difference in material behavior lies in fatigue causing permanent damage through accumulated microstructural changes under repeated loading, while elastic deformation involves no permanent changes under temporary or one-time loads.

Real-world Examples: Fatigue Failure vs. Elastic Recovery

Fatigue failure occurs in aircraft wings after thousands of flight cycles, where repeated stress causes microscopic cracks that grow until the wing fractures, whereas elastic deformation enables bridge cables to stretch under load and return to their original shape without permanent damage. In automotive suspensions, fatigue failure leads to broken control arms after prolonged use, while elastic deformation allows shock absorbers to compress and rebound effectively, maintaining ride comfort. Understanding the difference between these phenomena is critical for designing components that endure cyclic loading without experiencing irreversible damage or catastrophic failure.

Mitigating Fatigue and Enhancing Elastic Performance

Mitigating fatigue involves controlling cyclic stress through material selection, surface treatments, and design optimization to reduce crack initiation and propagation. Enhancing elastic performance requires using materials with high elastic modulus and resilience, allowing structures to endure loads without permanent deformation. Implementing fatigue-resistant alloys and ensuring components operate below the material's endurance limit significantly improve long-term durability and elastic behavior.

Fatigue Infographic

libterm.com

libterm.com