Counter-flow refers to a system where two fluids move in opposite directions to maximize heat exchange efficiency, commonly used in heat exchangers and cooling systems. This method enhances thermal transfer by maintaining a constant temperature gradient across the surfaces in contact. Discover how counter-flow designs can optimize your system's performance by reading further into this comprehensive guide.

Table of Comparison

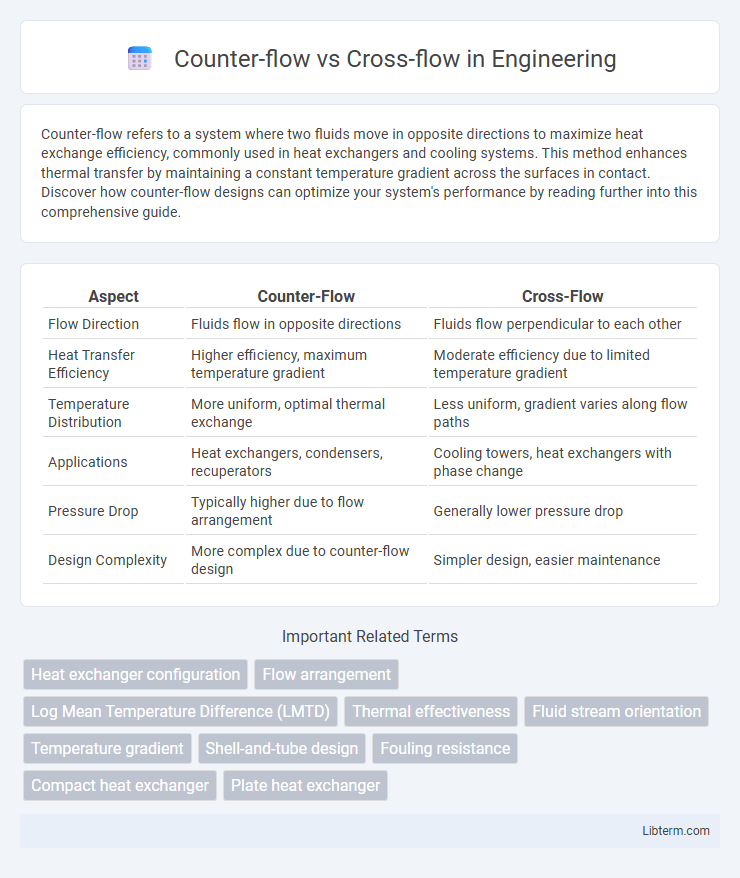

| Aspect | Counter-Flow | Cross-Flow |

|---|---|---|

| Flow Direction | Fluids flow in opposite directions | Fluids flow perpendicular to each other |

| Heat Transfer Efficiency | Higher efficiency, maximum temperature gradient | Moderate efficiency due to limited temperature gradient |

| Temperature Distribution | More uniform, optimal thermal exchange | Less uniform, gradient varies along flow paths |

| Applications | Heat exchangers, condensers, recuperators | Cooling towers, heat exchangers with phase change |

| Pressure Drop | Typically higher due to flow arrangement | Generally lower pressure drop |

| Design Complexity | More complex due to counter-flow design | Simpler design, easier maintenance |

Introduction to Heat Exchangers

Counter-flow heat exchangers provide higher thermal efficiency by allowing the hot and cold fluids to flow in opposite directions, maximizing the temperature gradient along the heat transfer surface. Cross-flow heat exchangers feature perpendicular fluid streams, often used where space constraints exist but typically deliver lower overall heat transfer efficiency compared to counter-flow designs. Understanding the flow arrangement is critical for optimizing heat exchanger performance in industrial applications such as power plants, HVAC systems, and chemical processing.

Defining Counter-Flow Heat Exchange

Counter-flow heat exchange features two fluids moving in opposite directions, maximizing the temperature gradient along the entire heat exchanger length for efficient thermal energy transfer. This design maintains a nearly constant temperature difference, enhancing heat transfer rates compared to cross-flow arrangements where fluids move perpendicular to each other. Counter-flow heat exchangers are widely used in applications requiring high thermal efficiency, such as condensers, evaporators, and industrial process systems.

Understanding Cross-Flow Heat Exchange

Cross-flow heat exchange involves two fluids flowing perpendicular to each other, enhancing heat transfer efficiency by maintaining a constant temperature gradient along the heat exchanger surface. This design allows for effective thermal energy transfer in applications such as air conditioning, refrigeration, and industrial cooling systems. Cross-flow heat exchangers typically provide lower pressure drops and compact configurations compared to counter-flow, making them suitable for space-constrained environments.

Key Differences Between Counter-Flow and Cross-Flow

Counter-flow heat exchangers allow fluids to flow in opposite directions, maximizing thermal gradient and heat transfer efficiency, while cross-flow configurations have fluids moving perpendicular to each other, resulting in moderate heat transfer performance. Counter-flow systems tend to achieve higher temperature differences between inlet and outlet streams due to better temperature profiles, whereas cross-flow designs are commonly used when compactness and ease of maintenance are prioritized. The selection between counter-flow and cross-flow depends on application-specific factors such as required heat transfer rate, pressure drop limitations, and spatial constraints.

Efficiency Comparison: Counter-Flow vs Cross-Flow

Counter-flow heat exchangers achieve higher thermal efficiency by maintaining a greater temperature gradient between fluids along the entire length, enabling more effective heat transfer compared to cross-flow designs. Cross-flow heat exchangers typically have lower efficiency due to the perpendicular flow paths, resulting in reduced temperature differences and less optimal heat exchange. The counter-flow arrangement can approach the maximum possible heat recovery, often exceeding the efficiency of cross-flow configurations by 10-20%.

Typical Applications for Each Flow Arrangement

Counter-flow heat exchangers are widely used in applications requiring high thermal efficiency, such as power plants and chemical processing where maximum heat transfer is critical. Cross-flow heat exchangers commonly appear in HVAC systems, automobile radiators, and air conditioning units due to their compact design and ability to handle large volumes of fluids. Industries select counter-flow arrangements for high-temperature differentials and cross-flow setups when space constraints and fluid separation are priorities.

Advantages of Counter-Flow Heat Exchangers

Counter-flow heat exchangers offer superior thermal efficiency by maintaining a higher temperature gradient between the fluids throughout the exchanger. This design allows for greater heat transfer rates compared to cross-flow configurations, resulting in improved energy recovery and lower operational costs. Enhanced temperature control also minimizes thermal stress and extends the lifespan of the heat exchanger components.

Benefits and Limitations of Cross-Flow Designs

Cross-flow heat exchangers offer effective thermal performance with simpler construction and enhanced ease of maintenance compared to counter-flow designs. Their design enables efficient handling of large volumetric flow rates and better resistance to fouling in applications like air conditioning and gas cooling. However, cross-flow heat exchangers typically achieve lower heat transfer efficiency and temperature difference driving force than counter-flow configurations, limiting their use in processes requiring maximum thermal energy recovery.

Selection Criteria: When to Use Each Type

Counter-flow heat exchangers excel in applications requiring maximum temperature gradient efficiency, ideal for processes needing close temperature approaches and high heat recovery. Cross-flow heat exchangers suit scenarios with space constraints and where fluids have different phase states or flow characteristics, offering simpler construction and cost-effectiveness. Selecting between counter-flow and cross-flow depends on factors like thermal performance requirements, fluid properties, pressure drop limits, and installation space.

Conclusion: Choosing the Optimal Heat Exchanger

Selecting the optimal heat exchanger hinges on process requirements such as temperature efficiency and fluid flow arrangements. Counter-flow heat exchangers maximize thermal performance by maintaining a higher temperature gradient along the heat exchange surface, making them ideal for applications requiring precise temperature control. Cross-flow designs provide flexibility and compactness, suited for systems with varying flow rates and space constraints.

Counter-flow Infographic

libterm.com

libterm.com