Butterfly valves offer efficient flow control with a compact design, making them ideal for various industrial applications including water supply, HVAC, and chemical processing. Their quarter-turn operation and lightweight structure enable quick shutoff and easy maintenance, enhancing system reliability and performance. Discover how butterfly valves can optimize Your fluid control needs by exploring the detailed benefits and selection tips in the rest of the article.

Table of Comparison

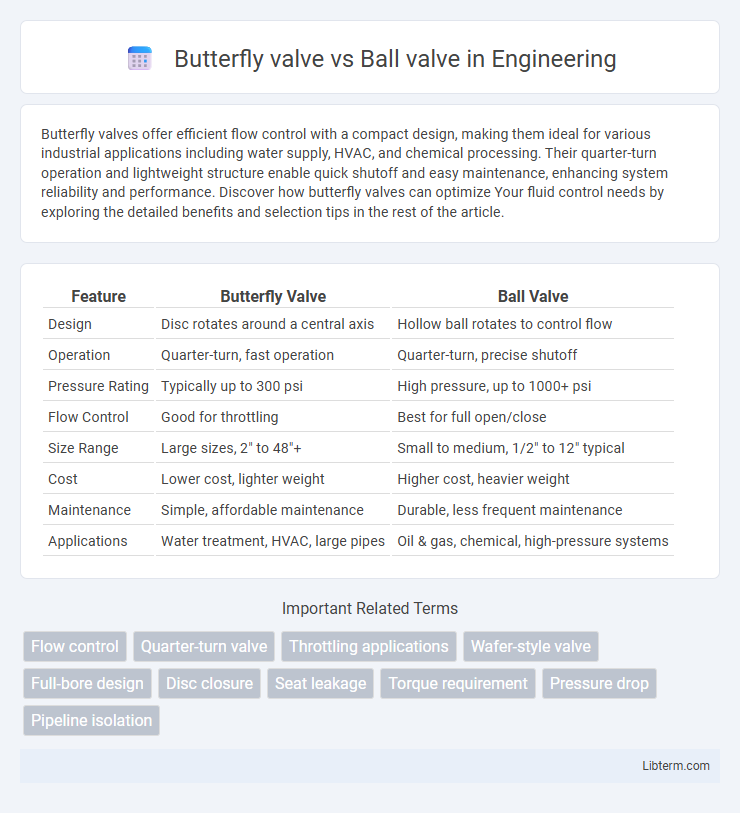

| Feature | Butterfly Valve | Ball Valve |

|---|---|---|

| Design | Disc rotates around a central axis | Hollow ball rotates to control flow |

| Operation | Quarter-turn, fast operation | Quarter-turn, precise shutoff |

| Pressure Rating | Typically up to 300 psi | High pressure, up to 1000+ psi |

| Flow Control | Good for throttling | Best for full open/close |

| Size Range | Large sizes, 2" to 48"+ | Small to medium, 1/2" to 12" typical |

| Cost | Lower cost, lighter weight | Higher cost, heavier weight |

| Maintenance | Simple, affordable maintenance | Durable, less frequent maintenance |

| Applications | Water treatment, HVAC, large pipes | Oil & gas, chemical, high-pressure systems |

Introduction to Butterfly Valve and Ball Valve

Butterfly valves feature a rotating disc positioned in the center of the pipe, enabling quick throttling and flow control in piping systems. Ball valves consist of a spherical closure unit with a hole through the center, providing reliable sealing and precise shut-off for liquids and gases. Both valve types are essential in industrial applications for regulating flow but differ in design, operation speed, and space requirements.

Design and Construction Differences

Butterfly valves feature a thin, disc-shaped closure mounted on a rotating shaft, providing quick quarter-turn operation and compact design ideal for large diameter pipelines. Ball valves use a spherical ball with a central bore, offering tight sealing and minimal pressure drop, suitable for high-pressure applications. The butterfly valve's lightweight construction contrasts with the more robust, heavier design of ball valves, affecting installation and maintenance requirements.

Working Principle Comparison

Butterfly valves operate by rotating a disc within the valve body to regulate flow, allowing for quick shut-off and throttling with a quarter-turn motion. Ball valves use a spherical ball with a bore that rotates 90 degrees to start or stop flow, providing tight sealing and minimal pressure drop when fully open. The butterfly valve's design is suited for larger diameter pipes and lower pressure applications, while ball valves excel in high-pressure systems requiring reliable sealing.

Flow Control Efficiency

Butterfly valves provide precise flow control with minimal pressure drop, making them ideal for applications requiring throttling and frequent operation. Ball valves offer excellent shut-off capabilities but typically have less nuanced flow regulation due to their quarter-turn design. The choice between butterfly and ball valves depends on the required balance between flow control efficiency and sealing performance in industrial systems.

Pressure and Temperature Handling

Butterfly valves typically handle pressures up to 150 psi and temperature ranges from -20degF to 450degF, making them suitable for low to moderate pressure systems with moderate temperature requirements. Ball valves can withstand higher pressures up to 1000 psi or more and operate efficiently in temperatures ranging from -40degF to 450degF, offering more robust performance in high-pressure and extreme temperature environments. The choice between butterfly and ball valves depends on the specific pressure ratings and temperature conditions of the application.

Installation and Space Requirements

Butterfly valves require less installation space due to their compact, wafer-style design, making them ideal for tight piping systems and applications needing quick operation. Ball valves, though generally bulkier, offer easier integration with flanged or threaded pipe connections, suitable for systems where space is less constrained but robust sealing is essential. Choosing between these valves involves balancing installation space availability with the specific piping setup and maintenance access requirements.

Maintenance and Durability

Butterfly valves require less maintenance due to their simple design and fewer moving parts, making them ideal for applications with low-pressure systems. Ball valves offer superior durability with robust construction, resisting wear and tear in high-pressure and high-temperature environments, but they may need more frequent inspection to ensure seal integrity. Both valve types benefit from regular lubrication and cleaning to extend operational lifespan and maintain optimal performance.

Cost Differences and ROI

Butterfly valves typically offer lower initial costs due to their simple design and lighter materials, making them cost-effective for large-diameter applications. Ball valves, while more expensive upfront, provide superior sealing and durability, resulting in lower maintenance costs and longer service life that can enhance ROI in high-pressure or critical systems. Evaluating total cost of ownership, butterfly valves excel in budget-sensitive projects, whereas ball valves deliver better value over time through reduced downtime and reliability.

Typical Applications in Industry

Butterfly valves are commonly used in large-diameter pipelines for water distribution, HVAC systems, and fire protection due to their lightweight design and quick operation. Ball valves are preferred in industries such as oil and gas, chemical processing, and pharmaceuticals for their tight seal and reliable shut-off capabilities. Both valves serve critical roles in controlling fluid flow, with butterfly valves favored for throttling and ball valves for high-pressure isolation tasks.

Choosing the Right Valve: Key Considerations

Selecting the right valve between butterfly and ball valves requires evaluating flow control precision, pressure ratings, and maintenance needs. Butterfly valves offer compact size and quick operation suited for throttling or large-diameter applications, while ball valves provide superior sealing and durability in high-pressure systems. Material compatibility and application specifics, such as temperature range and media type, are critical factors influencing the optimal choice.

Butterfly valve Infographic

libterm.com

libterm.com