Yielding is a fundamental concept in materials science that describes the point at which a material begins to deform plastically under stress, no longer returning to its original shape when the load is removed. Understanding yield stress and how different materials respond to varying forces is crucial for designing safe and efficient structures. Discover more about the mechanisms behind yielding and its practical implications by reading the full article.

Table of Comparison

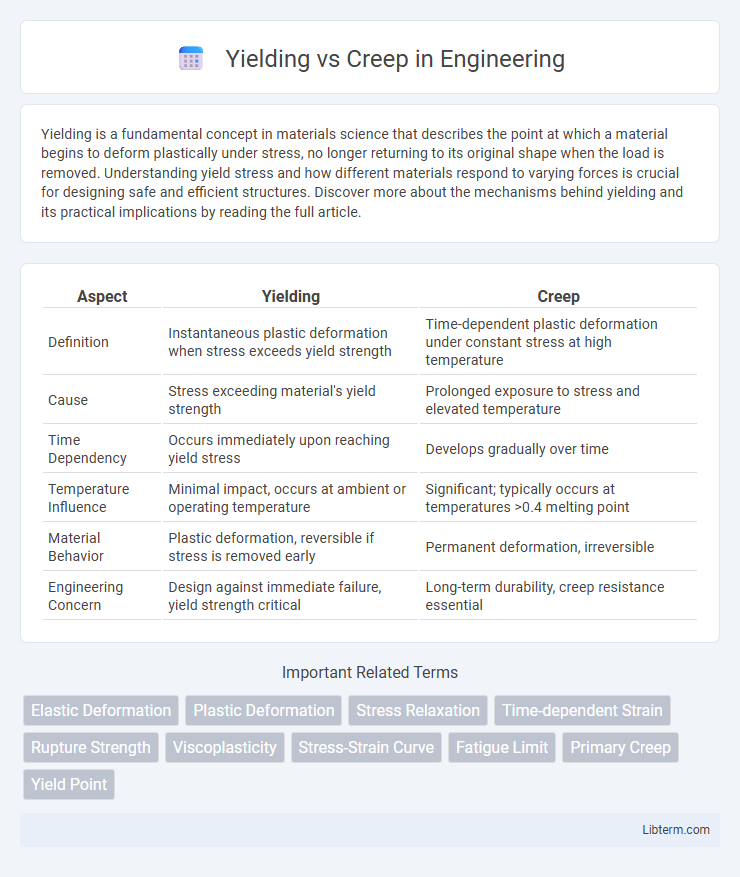

| Aspect | Yielding | Creep |

|---|---|---|

| Definition | Instantaneous plastic deformation when stress exceeds yield strength | Time-dependent plastic deformation under constant stress at high temperature |

| Cause | Stress exceeding material's yield strength | Prolonged exposure to stress and elevated temperature |

| Time Dependency | Occurs immediately upon reaching yield stress | Develops gradually over time |

| Temperature Influence | Minimal impact, occurs at ambient or operating temperature | Significant; typically occurs at temperatures >0.4 melting point |

| Material Behavior | Plastic deformation, reversible if stress is removed early | Permanent deformation, irreversible |

| Engineering Concern | Design against immediate failure, yield strength critical | Long-term durability, creep resistance essential |

Introduction to Yielding and Creep

Yielding refers to the permanent deformation of a material when subjected to stress beyond its elastic limit, causing it to lose its original shape. Creep is the time-dependent, gradual deformation of a material under constant stress, typically occurring at high temperatures. Both yielding and creep are critical factors in structural engineering, influencing the long-term performance and safety of materials such as metals, polymers, and composites.

Defining Yielding: Key Concepts

Yielding refers to the immediate deformation of a material when subjected to stress exceeding its yield strength, marking the transition from elastic to plastic behavior. This permanent change in shape occurs without a significant increase in load, indicating the onset of plastic flow in metals and alloys. Understanding yield strength is essential for determining the load limits and ensuring structural integrity in engineering applications.

Understanding Creep: An Overview

Creep refers to the time-dependent, permanent deformation of materials under constant stress, typically occurring at high temperatures or over extended periods. Unlike yielding, which happens rapidly once the material's elastic limit is surpassed, creep progresses slowly through primary, secondary, and tertiary stages, ultimately leading to material failure. Understanding creep behavior is crucial for designing components in aerospace, power plants, and structural applications where long-term mechanical stability is essential.

Differences in Mechanisms: Yielding vs Creep

Yielding occurs when a material undergoes immediate plastic deformation upon reaching its yield strength due to applied stress, whereas creep involves slow, time-dependent deformation under a constant load, typically at elevated temperatures. The mechanism of yielding is dominated by dislocation movement and slip within the crystal structure, while creep deformation arises from processes such as diffusion, grain boundary sliding, and dislocation climb. Yielding represents a sudden change in strain, whereas creep evolves gradually, often leading to failure over prolonged periods under sustained stress.

Stress-Strain Relationships in Yielding and Creep

Yielding and creep describe different stress-strain behaviors under load; yielding occurs when a material undergoes plastic deformation at a specific yield stress, resulting in a distinct deviation from linear elasticity on the stress-strain curve. Creep involves time-dependent strain under constant stress, where strain gradually increases even below the yield stress, characterized by primary, secondary, and tertiary creep stages in the creep curve. The yield stress defines the elastic limit at which permanent deformation begins, whereas creep strain accumulates progressively due to atomic diffusion or dislocation motion at elevated temperatures over extended periods.

Factors Influencing Yielding and Creep

Yielding in materials primarily depends on stress level, temperature, and strain rate, with higher stresses and elevated temperatures accelerating plastic deformation. Creep behavior is influenced by sustained stress, temperature near the material's melting point, time duration, and microstructural factors such as grain size and phase composition. Both phenomena are critically affected by environmental conditions, including oxidation and humidity, which can alter material properties and deformation mechanisms.

Impact on Material Selection and Engineering Design

Yielding defines the elastic limit at which a material undergoes permanent deformation under stress, influencing the selection of metals with appropriate yield strength for structural applications. Creep represents time-dependent plastic deformation under constant load and high temperature, critical for materials in turbines, boilers, and aerospace components requiring long-term dimensional stability. Engineers must balance yield strength and creep resistance to ensure safety, durability, and performance in environments involving mechanical loads and elevated temperatures.

Real-World Applications of Yielding and Creep

Yielding in materials is critical for applications like automotive crash components and structural beams, where controlled deformation prevents sudden failures. Creep behavior is essential in high-temperature environments such as turbine blades and nuclear reactors, where long-term deformation under constant stress can compromise integrity. Designing for yielding involves ensuring materials absorb impact energy, while addressing creep requires selecting alloys resistant to time-dependent strain at elevated temperatures.

Prevention and Control Strategies

Yielding and creep are deformation processes that occur under stress, where yielding involves immediate plastic deformation and creep represents time-dependent strain at elevated temperatures. Prevention strategies for yielding include material selection with high yield strength and design improvements to reduce stress concentrations, while creep control relies on using heat-resistant alloys, applying surface treatments, and maintaining operating temperatures below critical thresholds. Implementing proper maintenance schedules and monitoring stress and temperature conditions are essential for controlling both yielding and creep in engineering applications.

Summary and Future Trends

Yielding involves immediate, permanent deformation of materials under stress, whereas creep refers to time-dependent, gradual deformation under sustained load, primarily at high temperatures. Advances in material science focus on developing alloys and composites with enhanced resistance to both yielding and creep, improving structural durability in aerospace and power generation industries. Future trends emphasize real-time monitoring technologies and predictive modeling using AI to optimize material performance under variable operational conditions.

Yielding Infographic

libterm.com

libterm.com