Effective drying techniques are essential for preserving the quality and longevity of various materials, reducing moisture content to prevent mold and decay. Understanding the best drying methods tailored to your specific needs ensures optimal results whether in food preservation, industrial processes, or textile care. Explore this article to discover expert tips and innovative drying solutions that can maximize efficiency and maintain product integrity.

Table of Comparison

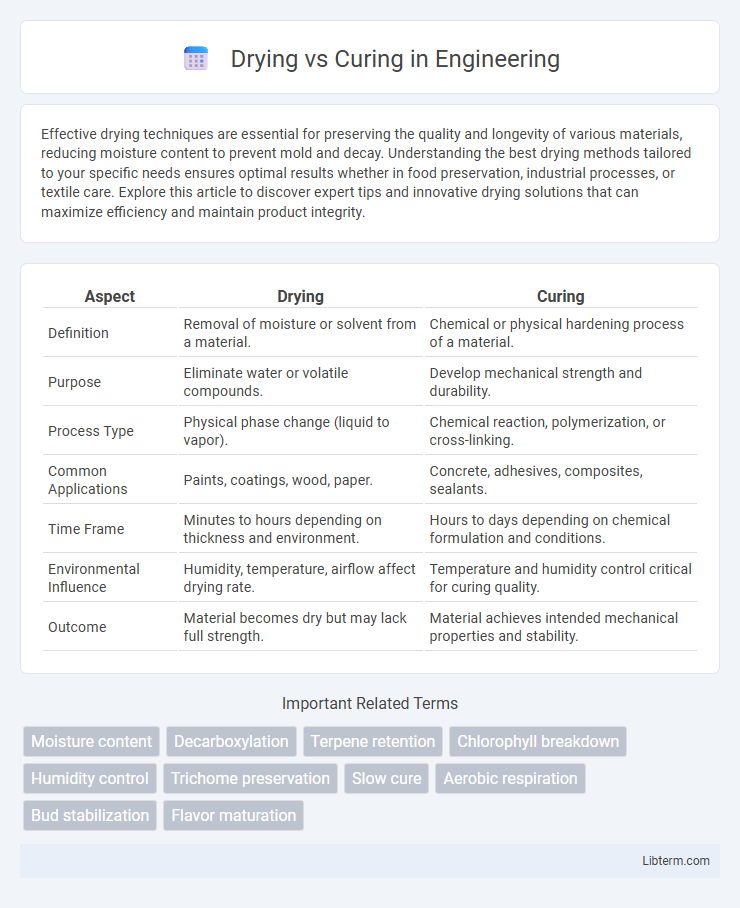

| Aspect | Drying | Curing |

|---|---|---|

| Definition | Removal of moisture or solvent from a material. | Chemical or physical hardening process of a material. |

| Purpose | Eliminate water or volatile compounds. | Develop mechanical strength and durability. |

| Process Type | Physical phase change (liquid to vapor). | Chemical reaction, polymerization, or cross-linking. |

| Common Applications | Paints, coatings, wood, paper. | Concrete, adhesives, composites, sealants. |

| Time Frame | Minutes to hours depending on thickness and environment. | Hours to days depending on chemical formulation and conditions. |

| Environmental Influence | Humidity, temperature, airflow affect drying rate. | Temperature and humidity control critical for curing quality. |

| Outcome | Material becomes dry but may lack full strength. | Material achieves intended mechanical properties and stability. |

Understanding Drying and Curing: Key Differences

Drying involves the removal of moisture from a substance, primarily through evaporation, resulting in a reduced water content that helps prevent spoilage and decay. Curing, on the other hand, is a preservation process that combines drying with the application of salts, sugars, or nitrates to inhibit microbial growth and enhance flavor and texture. Understanding these key differences is crucial, as drying primarily reduces moisture, while curing chemically alters the food to extend shelf life and improve quality.

The Science Behind Drying and Curing

The science behind drying and curing involves distinct biochemical and physical processes that optimize product quality and longevity. Drying primarily removes moisture through evaporation, inhibiting microbial growth and enzymatic reactions, while curing involves controlled chemical transformations like protein denaturation and flavor compound development. These processes are essential in industries such as food preservation, pharmaceuticals, and cannabis cultivation, where moisture control and chemical stability directly impact efficacy and shelf life.

Importance of Proper Drying Methods

Proper drying methods are essential to prevent mold growth and preserve the quality of harvested produce or materials. Controlled drying conditions ensure moisture content is reduced evenly, preventing spoilage and maintaining optimal texture, flavor, and potency. Implementing precise temperature and humidity controls enhances shelf life and overall product stability during the curing process.

Why Curing Matters for Quality

Curing enhances the chemical composition and potency of cannabis by allowing chlorophyll and harsh compounds to break down, resulting in a smoother, more flavorful smoke. Proper curing reduces moisture content to optimal levels, preventing mold growth and preserving cannabinoids and terpenes. This meticulous process ultimately improves aroma, taste, and overall product stability, making curing essential for premium cannabis quality.

Comparing Techniques: Drying vs Curing

Drying removes moisture from materials, primarily to prevent spoilage and enable storage, while curing involves chemical or physical processes that enhance flavor, texture, and preservation by interaction with salts, sugars, or smoke. Drying techniques include air drying, sun drying, and dehydrating, which primarily reduce water content, whereas curing methods may involve salting, brining, or smoking, adding antimicrobial and antioxidative properties. Both techniques extend shelf life, but curing often imparts distinctive flavors and textures, making it preferred for meats and certain vegetables compared to the simpler preservation goal of drying.

Common Mistakes in Drying and Curing Processes

Common mistakes in drying include insufficient airflow and excessive temperatures, which can lead to uneven moisture removal and degradation of active compounds. In curing, failing to maintain consistent humidity and temperature control often results in mold growth or loss of aroma and potency. Both processes require precise environmental regulation to preserve quality and prevent contamination.

Best Environmental Conditions for Drying and Curing

Optimal environmental conditions for drying cannabis include temperatures between 60-70degF (15-21degC) with relative humidity levels of 45-55%, ensuring slow moisture evaporation to preserve terpenes and cannabinoids. During curing, humidity should be maintained around 60-65% in sealed containers, with temperatures maintained between 60-70degF to allow gradual chemical transformations and enhance flavor and potency. Controlled airflow and darkness are crucial throughout both processes to prevent mold growth and degradation of sensitive compounds.

How Timing Impacts Drying and Curing Success

Timing plays a critical role in the success of drying and curing processes, as inadequate or excessive duration can affect moisture content and flavor development. Proper drying time ensures the removal of excess water to prevent mold growth, while precise curing timing allows enzymatic reactions to enhance texture, aroma, and potency. Monitoring environmental factors such as temperature and humidity during specific drying and curing periods optimizes product quality and shelf life.

Effects on Flavor, Potency, and Product Longevity

Drying removes excess moisture from cannabis, stabilizing the product and preventing mold, which preserves potency and creates a smoother smoke but can result in less developed flavor profiles. Curing promotes chemical changes by allowing cannabinoids and terpenes to mature, significantly enhancing flavor complexity, increasing potency through decarboxylation, and extending product longevity by preventing degradation. Proper curing optimizes terpene retention and cannabinoid stability, making it crucial for maximizing both sensory experience and shelf life.

Final Tips for Achieving Optimal Results

For optimal results in drying and curing, maintain consistent temperature and humidity levels--ideal drying occurs at 60-70degF with 45-55% humidity, while curing thrives at 60-70degF and 60-65% humidity. Use airtight containers for curing, opening them daily for 10-15 minutes during the first two weeks to release excess moisture and prevent mold growth. Monitor weight and texture regularly to ensure buds are neither too dry nor too moist, preserving potency and flavor.

Drying Infographic

libterm.com

libterm.com