Flying form refers to a digital or online form used for booking flights, submitting travel information, or arranging air travel services. These forms streamline your travel planning by allowing you to enter passenger details, flight preferences, and payment information quickly and securely. Explore the rest of the article to learn how to efficiently use flying forms for a hassle-free booking experience.

Table of Comparison

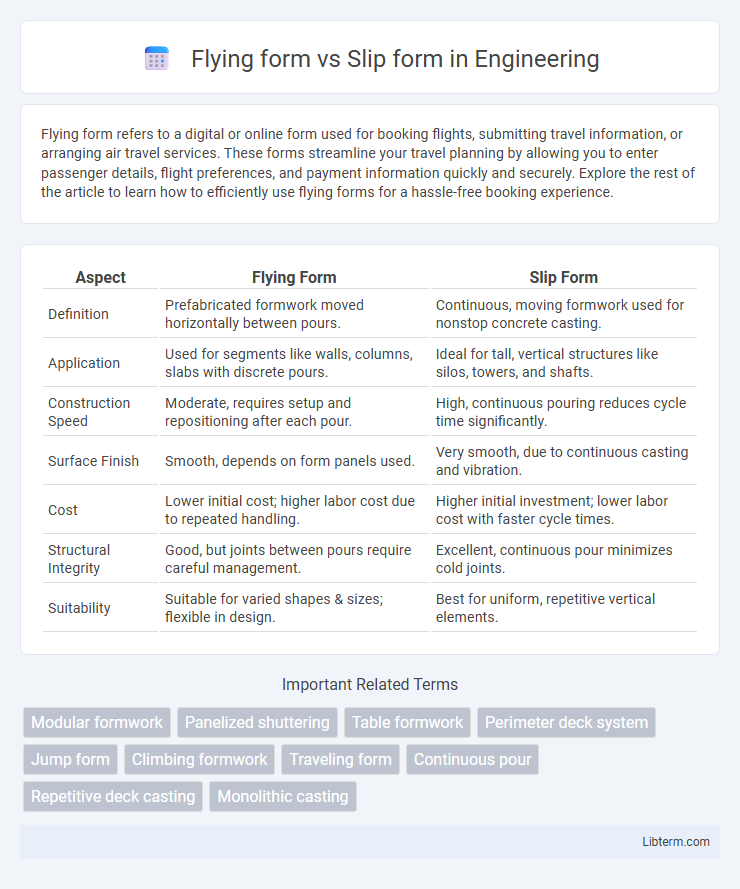

| Aspect | Flying Form | Slip Form |

|---|---|---|

| Definition | Prefabricated formwork moved horizontally between pours. | Continuous, moving formwork used for nonstop concrete casting. |

| Application | Used for segments like walls, columns, slabs with discrete pours. | Ideal for tall, vertical structures like silos, towers, and shafts. |

| Construction Speed | Moderate, requires setup and repositioning after each pour. | High, continuous pouring reduces cycle time significantly. |

| Surface Finish | Smooth, depends on form panels used. | Very smooth, due to continuous casting and vibration. |

| Cost | Lower initial cost; higher labor cost due to repeated handling. | Higher initial investment; lower labor cost with faster cycle times. |

| Structural Integrity | Good, but joints between pours require careful management. | Excellent, continuous pour minimizes cold joints. |

| Suitability | Suitable for varied shapes & sizes; flexible in design. | Best for uniform, repetitive vertical elements. |

Introduction to Flying Form and Slip Form

Flying form and slip form are advanced concrete formwork techniques used in large-scale construction to enhance efficiency and productivity. Flying form involves pre-assembled, reusable formwork panels that are moved horizontally to the next pour location using cranes, enabling rapid cycle times for floors and slabs. Slip form continuously moves vertically as concrete is poured, allowing seamless, uninterrupted construction of tall structures like silos, towers, and bridge piers.

Key Concepts: What is Flying Form?

Flying form is a construction technique where reusable formwork is swiftly relocated from one pour to the next, enabling high-speed concrete slab casting commonly used in multi-story buildings. This method relies on modular form panels mounted on wheeled or crane-lifted frames, minimizing downtime between pours and maximizing efficiency. Unlike slip form, flying form does not require continuous concrete placement, allowing precise setting and surface finish control for each floor level.

Key Concepts: What is Slip Form?

Slip form is a continuous concrete pouring method used in construction to create tall structures such as silos, towers, and bridges efficiently. This technique involves a moving formwork system that rises incrementally as the concrete sets, providing a seamless and uniform structure without joints. Slip form offers advantages like faster construction times, improved structural integrity, and reduced labor costs compared to traditional flying form methods.

Core Differences Between Flying Form and Slip Form

Flying form involves a movable formwork system that is raised and relocated by cranes, enabling rapid repetitive concrete pours in building floors or walls, while slip form uses continuous vertical movement of formwork supported by hydraulic jacks for uninterrupted concrete placement, ideal for tall structures like silos and towers. The core difference lies in flying form's batch-based cycle versus slip form's continuous operation. Flying forms allow for precision and flexibility between pours, whereas slip form maximizes efficiency in tall, uniform structures without form removal until completion.

Advantages of Flying Form Construction

Flying form construction significantly accelerates high-rise building projects by enabling rapid and repetitive slab casting with minimal repositioning time. This method enhances safety and labor efficiency through integrated platforms and guardrails, reducing manual handling and fall risks. Its modular design minimizes material waste and allows for precise alignment, improving structural quality and overall cost-effectiveness in large-scale concrete construction.

Advantages of Slip Form Construction

Slip form construction offers continuous pouring of concrete, resulting in faster project completion and reduced labor costs compared to flying form methods. The process ensures uniformity and structural integrity by minimizing cold joints, enhancing the durability of high-rise buildings and large infrastructure projects. Slip form systems provide flexibility for complex shapes and vertical structures, optimizing site safety and enabling efficient material usage.

Best Use Cases for Flying Form

Flying form systems are best suited for large-scale construction projects requiring rapid, repetitive concrete slab work, such as multi-story buildings, bridges, and parking structures. This method accelerates construction cycles by enabling entire formwork units to be moved and reused with minimal downtime, optimizing productivity for projects with uniform floor layouts. Flying forms provide high precision and quality finishes, making them ideal for urban construction sites where time efficiency and structural accuracy are critical.

Best Use Cases for Slip Form

Slip form is best suited for continuous vertical concrete structures such as silos, chimneys, water towers, and elevator shafts due to its ability to create seamless, uniform walls with enhanced structural integrity. The method excels in large-scale projects requiring rapid construction cycles and consistent wall thickness, optimizing labor efficiency and concrete quality. Flying form is more appropriate for horizontal surfaces like slabs and floors, making slip form the superior choice for tall, cylindrical, or tapered structures.

Factors to Consider When Choosing Formwork System

Choosing between flying form and slip form systems depends on project duration, height, and repetition of structural elements. Flying forms are ideal for horizontal slabs in high-rise buildings due to their rapid reuse and ease of movement, while slip forms excel in continuous vertical structures such as silos or towers because of their seamless, uninterrupted pouring. Budget constraints, labor availability, and site conditions also influence the optimal choice, with flying forms requiring more crane operations and slip forms demanding precise coordination for continuous concrete placement.

Conclusion: Choosing the Right Formwork Method

Selecting between flying form and slip form depends largely on project requirements such as speed, surface finish, and structural complexity. Flying forms offer rapid reuse for horizontal concrete surfaces, ideal for slabs and floors, while slip forms provide continuous vertical concrete placement suited for tall structures like silos and towers. Evaluating factors like project scale, budget, and desired finish quality ensures the optimal formwork method is chosen for maximum efficiency and structural integrity.

Flying form Infographic

libterm.com

libterm.com