Butterfly valves provide efficient flow control in pipelines by using a rotating disc to regulate fluid passage, combining durability with compact design. Their quick operation and minimal pressure drop make them ideal for applications across water supply, HVAC, and chemical industries. Discover how butterfly valves can enhance your system's performance by exploring the key features and benefits in the full article.

Table of Comparison

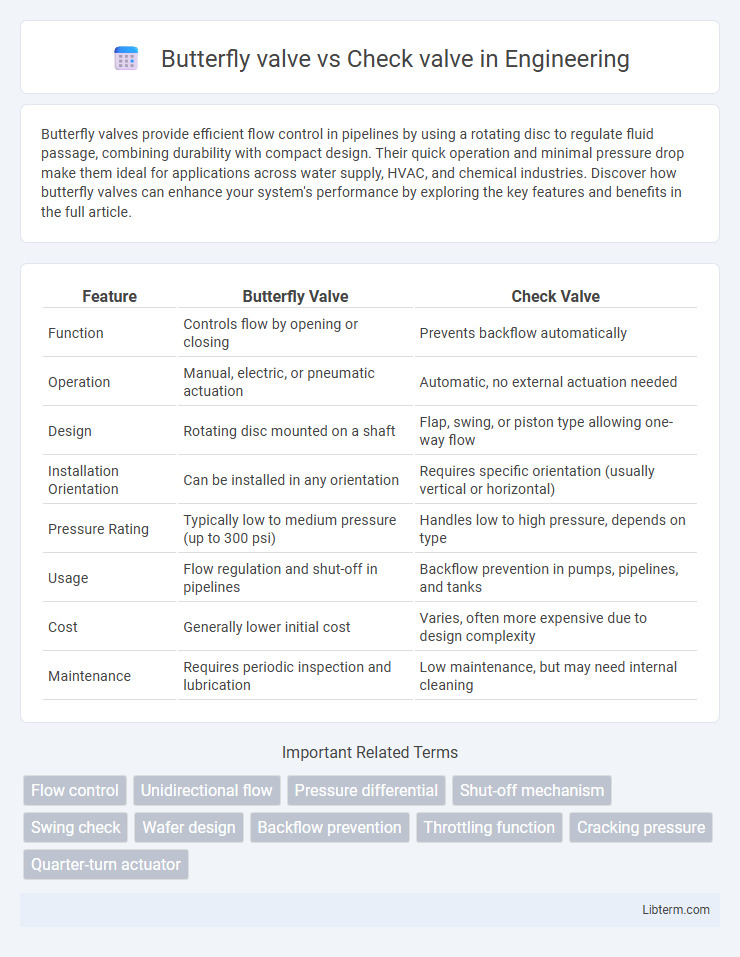

| Feature | Butterfly Valve | Check Valve |

|---|---|---|

| Function | Controls flow by opening or closing | Prevents backflow automatically |

| Operation | Manual, electric, or pneumatic actuation | Automatic, no external actuation needed |

| Design | Rotating disc mounted on a shaft | Flap, swing, or piston type allowing one-way flow |

| Installation Orientation | Can be installed in any orientation | Requires specific orientation (usually vertical or horizontal) |

| Pressure Rating | Typically low to medium pressure (up to 300 psi) | Handles low to high pressure, depends on type |

| Usage | Flow regulation and shut-off in pipelines | Backflow prevention in pumps, pipelines, and tanks |

| Cost | Generally lower initial cost | Varies, often more expensive due to design complexity |

| Maintenance | Requires periodic inspection and lubrication | Low maintenance, but may need internal cleaning |

Introduction to Butterfly Valves and Check Valves

Butterfly valves utilize a rotating disc to regulate flow and are commonly used for quick shutoff in large pipe diameters, offering compact design and low pressure drop. Check valves, designed to prevent reverse flow, operate automatically and are essential for protecting pumps and compressors from backflow damage. Both valve types serve critical roles in controlling fluid direction but differ significantly in operation and application within piping systems.

Key Differences Between Butterfly Valves and Check Valves

Butterfly valves control fluid flow by rotating a disc within the valve body to open or close the passage, providing quick shutoff and throttling capabilities, whereas check valves allow flow in only one direction to prevent backflow without manual operation. Butterfly valves are commonly used in large pipe diameters and systems requiring frequent operation, while check valves are primarily used for fluid flow protection in pipelines to avoid reverse flow damage. The operational mechanisms differ significantly, with butterfly valves requiring external actuation and check valves functioning automatically based on flow dynamics.

How Butterfly Valves Work

Butterfly valves operate by rotating a disc within the valve body to regulate flow, where the disc pivots on a central shaft and can be positioned parallel or perpendicular to the flow path. The design provides quick shutoff capabilities, typically controlling flow in large pipe diameters with minimal pressure drop. This mechanism contrasts with check valves, which allow unidirectional flow and prevent backflow by automatically closing under reverse pressure.

How Check Valves Operate

Check valves operate by allowing fluid to flow in one direction while preventing backflow through a hinged or spring-loaded disc that closes when reverse flow occurs. These valves rely on pressure differences and gravity or spring tension to maintain a sealed position against the valve seat, ensuring unidirectional flow. Common applications include water systems, pumps, and pipelines where preventing reverse flow protects equipment and maintains system integrity.

Applications of Butterfly Valves

Butterfly valves are widely applied in water treatment, HVAC systems, and chemical processing due to their quick shut-off capabilities and compact design. They are ideal for regulating flow in large-diameter pipelines where space and weight limitations are critical. Unlike check valves, butterfly valves allow for precise flow control and can be operated manually or automatically, making them versatile in various industrial applications.

Applications of Check Valves

Check valves are essential in applications requiring unidirectional flow to prevent backflow in systems such as water and wastewater treatment, chemical processing, and oil and gas pipelines. They are commonly used in pump discharge lines, compressed air systems, and steam lines to protect equipment from damage caused by reverse flow. Their automatic operation without manual intervention makes them ideal for maintaining system integrity in HVAC, fire protection, and irrigation systems.

Advantages of Butterfly Valves

Butterfly valves offer compact design and lightweight structure, making them ideal for large-diameter pipes with limited space. Their quick quarter-turn operation allows for rapid opening and closing, enhancing flow control efficiency. These valves provide lower pressure drops and cost-effective maintenance compared to check valves, making them suitable for various industrial applications requiring reliable shut-off and throttling.

Benefits of Using Check Valves

Check valves prevent backflow in pipelines, ensuring unidirectional fluid flow and protecting pumps and compressors from damage. They require no manual intervention or external control, offering automatic operation and low maintenance costs. Their compact design and reliable sealing capabilities improve system efficiency and reduce downtime in industrial and plumbing applications.

Factors to Consider When Choosing Between Butterfly and Check Valves

Selecting between butterfly valves and check valves requires assessing factors such as flow control needs, pressure ratings, and installation constraints. Butterfly valves excel in modulating flow and are suitable for large-diameter pipelines with moderate pressure, while check valves are designed primarily for preventing reverse flow and are ideal for systems requiring one-way operation. Material compatibility, maintenance accessibility, and cost considerations also play critical roles in determining the optimal valve type for a specific application.

Conclusion: Selecting the Right Valve for Your System

Choosing between a butterfly valve and a check valve depends on system requirements such as flow control precision and unidirectional flow prevention. Butterfly valves offer cost-effective flow regulation with quick operation and minimal pressure drop, ideal for large pipe diameters. Check valves ensure fluid backflow prevention without manual intervention, suitable for safeguarding pumps and compressors in systems with steady flow direction.

Butterfly valve Infographic

libterm.com

libterm.com