Incremental encoders provide precise feedback by converting mechanical motion into electronic signals, essential for accurate position and speed measurement in industrial automation. These devices generate pulses corresponding to movement increments, allowing you to track rotational or linear displacement efficiently. Explore the rest of the article to understand how incremental encoders optimize performance in various applications.

Table of Comparison

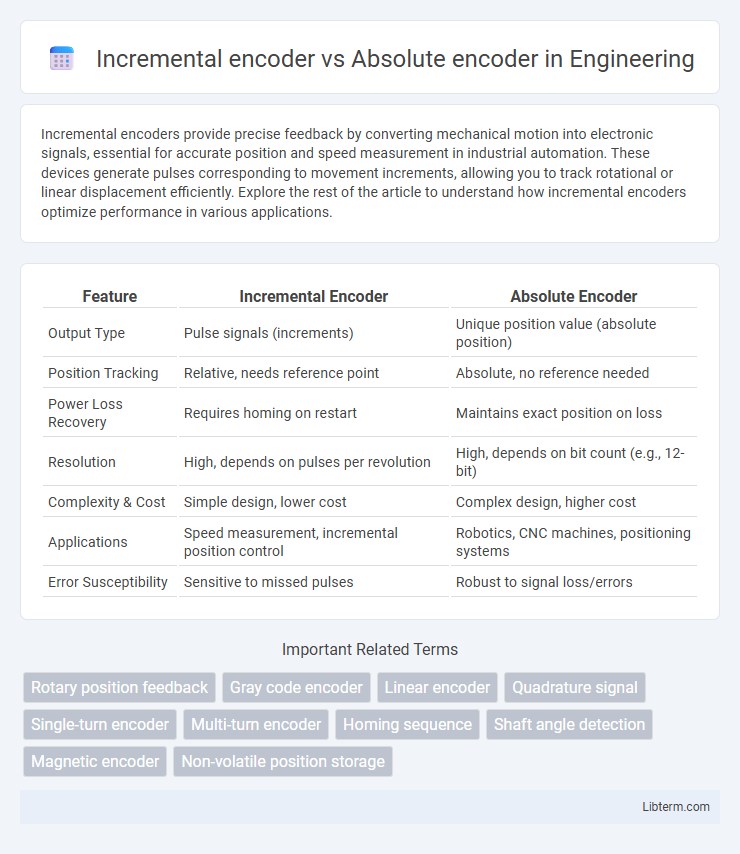

| Feature | Incremental Encoder | Absolute Encoder |

|---|---|---|

| Output Type | Pulse signals (increments) | Unique position value (absolute position) |

| Position Tracking | Relative, needs reference point | Absolute, no reference needed |

| Power Loss Recovery | Requires homing on restart | Maintains exact position on loss |

| Resolution | High, depends on pulses per revolution | High, depends on bit count (e.g., 12-bit) |

| Complexity & Cost | Simple design, lower cost | Complex design, higher cost |

| Applications | Speed measurement, incremental position control | Robotics, CNC machines, positioning systems |

| Error Susceptibility | Sensitive to missed pulses | Robust to signal loss/errors |

Introduction to Rotary Encoders

Rotary encoders convert mechanical motion into electrical signals for precise position and speed feedback in automation systems. Incremental encoders generate pulses relative to position changes, requiring a reference point for absolute positioning, while absolute encoders provide unique position values for each shaft angle without needing a homing sequence. Applications such as robotics and CNC machinery rely on the choice between incremental and absolute encoders based on accuracy, complexity, and environmental factors.

What is an Incremental Encoder?

An incremental encoder is a rotary or linear position sensor that generates pulses corresponding to movement, providing relative position information by counting these pulses from a reference point. It typically outputs two square wave signals, known as A and B channels, which are 90 degrees out of phase to determine direction. Incremental encoders are widely used in applications requiring precise speed and position control but lack inherent position memory after power loss.

What is an Absolute Encoder?

An absolute encoder provides a unique position value for each distinct shaft angle, offering precise and reliable feedback without requiring a reference point. It uses a multi-bit binary or Gray code output to represent the exact position, ensuring no loss of data during power interruptions. Commonly used in robotics, CNC machines, and industrial automation, absolute encoders enable accurate motion control and position tracking.

Key Differences Between Incremental and Absolute Encoders

Incremental encoders provide relative position information by generating pulses corresponding to movement, requiring a reference point for accurate positioning, while absolute encoders deliver unique position values for each shaft angle, enabling precise location tracking without the need for calibration. Incremental encoders typically offer simpler design and lower cost but lack position memory during power loss, whereas absolute encoders maintain position data with multi-turn or single-turn operation, enhancing reliability in critical applications. Resolution and output signal type also differ: incremental encoders produce quadrature signals for velocity and direction, whereas absolute encoders output digital or analog codes representing exact position.

Working Principle of Incremental Encoders

Incremental encoders generate output signals by detecting changes in position through a rotating disk with evenly spaced lines, producing pulses that correspond to incremental movement increments. These pulses are counted by an external controller to determine relative position, speed, and direction, with no inherent absolute position reference. Unlike absolute encoders, which provide unique position values at each point, incremental encoders rely on a home or zero reference to reset the position count during operation.

Working Principle of Absolute Encoders

Absolute encoders operate by providing a unique position value for every angular position of the shaft, using a coded disk with distinct binary patterns detected by optical or magnetic sensors. Unlike incremental encoders that emit pulses corresponding to motion increments, absolute encoders offer precise positional data directly, even after power loss, through multi-track encoding of shaft position. This enables absolute encoders to deliver reliable and accurate shaft position information essential for applications requiring exact feedback without reference resets.

Advantages of Incremental Encoders

Incremental encoders offer precise real-time feedback on position and speed with simpler and cost-effective design compared to absolute encoders. They provide high-resolution output and are highly suitable for applications requiring continuous monitoring of motion changes. Their ease of integration and ability to detect direction make them advantageous in industrial automation and robotics.

Advantages of Absolute Encoders

Absolute encoders provide precise position information by generating a unique code for each shaft angle, eliminating errors caused by power loss or system resets. They enable reliable and accurate feedback in automated systems, improving efficiency in applications where exact position tracking is critical. Their ability to maintain position data without needing a reference point significantly reduces downtime and maintenance costs compared to incremental encoders.

Typical Applications for Each Encoder Type

Incremental encoders are widely used in robotics, CNC machines, and conveyor systems where precise measurement of speed, direction, and relative position is essential for motion control. Absolute encoders find typical applications in industrial automation, robotics, and aerospace, providing unique position data essential for systems requiring exact reference points after power loss. Both encoder types are critical in servo motor feedback and robotics for accurate control, with incremental encoders favored for high-speed counting and absolute encoders ideal for precise positioning and repeatability.

How to Choose Between Incremental and Absolute Encoders

Choosing between incremental and absolute encoders depends on the application's need for position accuracy and system complexity. Incremental encoders are ideal for applications requiring relative position tracking and high-speed performance, offering simple installation and lower cost. Absolute encoders provide precise position data at power-up, essential for systems demanding exact position identification and immunity to power loss, despite higher complexity and price.

Incremental encoder Infographic

libterm.com

libterm.com