A fracture occurs when a bone breaks or cracks due to trauma, overuse, or underlying medical conditions. Recognizing the symptoms early, such as intense pain, swelling, and deformity, is crucial for prompt treatment and effective healing. Explore this article to understand fracture types, treatments, and recovery tips to protect your bone health.

Table of Comparison

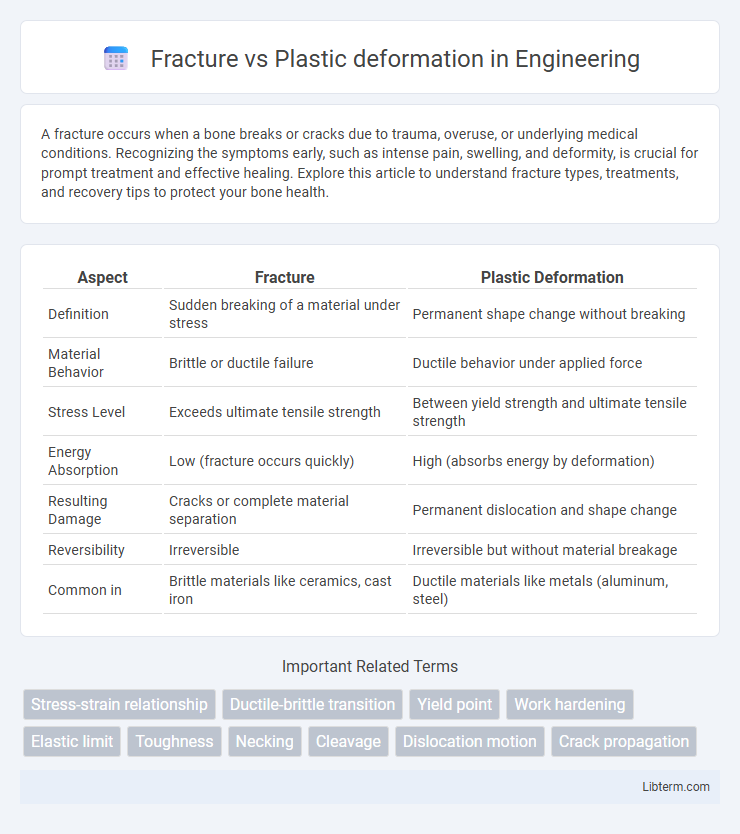

| Aspect | Fracture | Plastic Deformation |

|---|---|---|

| Definition | Sudden breaking of a material under stress | Permanent shape change without breaking |

| Material Behavior | Brittle or ductile failure | Ductile behavior under applied force |

| Stress Level | Exceeds ultimate tensile strength | Between yield strength and ultimate tensile strength |

| Energy Absorption | Low (fracture occurs quickly) | High (absorbs energy by deformation) |

| Resulting Damage | Cracks or complete material separation | Permanent dislocation and shape change |

| Reversibility | Irreversible | Irreversible but without material breakage |

| Common in | Brittle materials like ceramics, cast iron | Ductile materials like metals (aluminum, steel) |

Introduction to Fracture and Plastic Deformation

Fracture is the process where a material breaks or cracks under stress, leading to a sudden loss of load-bearing capacity, often characterized by crack initiation and propagation. Plastic deformation refers to the permanent change in shape or size of a material when subjected to stresses beyond its elastic limit, caused by dislocation movements within its crystal structure. Understanding the mechanisms of fracture and plastic deformation is crucial in materials science for predicting material behavior under mechanical loading.

Fundamental Definitions: Fracture vs Plastic Deformation

Fracture is the separation or breaking of a material into pieces under stress, occurring once the material's strength limit is exceeded. Plastic deformation refers to the permanent change in shape or size of a material when subjected to stress beyond its elastic limit but before fracture. The fundamental difference lies in fracture causing material failure, whereas plastic deformation involves irreversible shape change without complete failure.

Causes and Mechanisms of Fracture

Fracture occurs when a material experiences stress beyond its tensile strength, leading to crack initiation and propagation due to atomic bond failure, often influenced by factors such as stress concentration, material defects, and environmental conditions. Plastic deformation involves permanent shape change caused by dislocation motion and slip within the crystal lattice under applied stress but without immediate fracture. The mechanisms of fracture can be brittle, characterized by rapid crack growth with little plastic deformation, or ductile, involving significant plastic deformation before separation.

Causes and Mechanisms of Plastic Deformation

Plastic deformation occurs when a material undergoes irreversible shape change due to dislocation motion within its crystal lattice under applied stress, without fracturing. Causes include stress exceeding the yield strength, temperature effects facilitating atomic movement, and the presence of defects like grain boundaries that enable slip or twinning mechanisms. In contrast, fracture involves the propagation of cracks once the material can no longer accommodate plastic strain, leading to sudden separation.

Microstructural Differences: Fracture vs Plastic Deformation

Fracture involves the initiation and propagation of cracks through the microstructure, often occurring along grain boundaries, inclusions, or phase interfaces, leading to a sudden separation of the material. Plastic deformation is characterized by dislocation movement and slip within the crystalline lattice, resulting in permanent shape change without macroscopic material separation. Microstructurally, plastic deformation produces features like slip bands, twins, and strain hardening, whereas fracture generates cleavage facets, dimples, or intergranular cracks depending on the fracture mode.

Stress-Strain Behavior Comparison

Fracture and plastic deformation exhibit distinct stress-strain behavior where fracture is characterized by a sudden drop in stress following the elastic limit, indicating brittle failure without significant deformation. Plastic deformation shows a region beyond the elastic limit where the material undergoes permanent strain, marked by a yield point and strain hardening before eventual rupture. The stress-strain curve for fracture is typically linear up to the breaking point, whereas plastic deformation features a nonlinear curve with a notable strain plateau and increased ductility.

Factors Influencing Fracture and Plastic Deformation

Fracture and plastic deformation are influenced by material properties such as tensile strength, ductility, and microstructure, with factors like temperature, strain rate, and the presence of stress concentrators playing critical roles. High strain rates and low temperatures typically promote brittle fracture, while elevated temperatures and slow strain rates favor plastic deformation by enabling dislocation movement. Grain size, alloy composition, and the presence of defects further determine the material's susceptibility to fracture or its capacity for plastic deformation under applied stresses.

Material Types and Their Deformation Responses

Brittle materials such as ceramics and some hardened metals primarily exhibit fracture behavior, characterized by crack initiation and rapid propagation under stress, with minimal plastic deformation. Ductile materials like most metals undergo plastic deformation, showing significant dislocation movement and shape change before failure, allowing energy absorption and deformation without immediate cracking. Composite materials may demonstrate a combination of both responses depending on their matrix and reinforcement phases, affecting their overall toughness and failure mechanisms.

Engineering Applications and Implications

Fracture involves the sudden and complete separation of a material under stress, critically affecting the structural integrity and safety of engineered components such as bridges, aircraft, and pipelines. Plastic deformation allows materials to undergo permanent shape change without failure, enabling processes like metal forming, bending, and shaping in manufacturing industries. Understanding the balance between fracture toughness and ductility guides engineers in selecting materials and designing components that prevent catastrophic failure while maintaining performance and durability.

Conclusion: Key Differences and Practical Considerations

Fracture involves the complete separation of a material into parts under stress, characterized by crack initiation and propagation, while plastic deformation refers to the permanent shape change without breaking. Key differences include the material's behavior under load, with fracture indicating failure and plastic deformation indicating ductility and energy absorption capacity. Practical considerations involve selecting materials and designing components to either resist fracture for structural integrity or allow controlled plastic deformation to prevent sudden failure.

Fracture Infographic

libterm.com

libterm.com