A spot drill is an essential tool for creating precise starter holes, ensuring that drill bits do not wander during drilling operations. This technique enhances accuracy and extends the lifespan of your drill bits by producing clean, centered indentations on the material surface. Discover more about how spot drills can improve Your machining projects in the rest of this article.

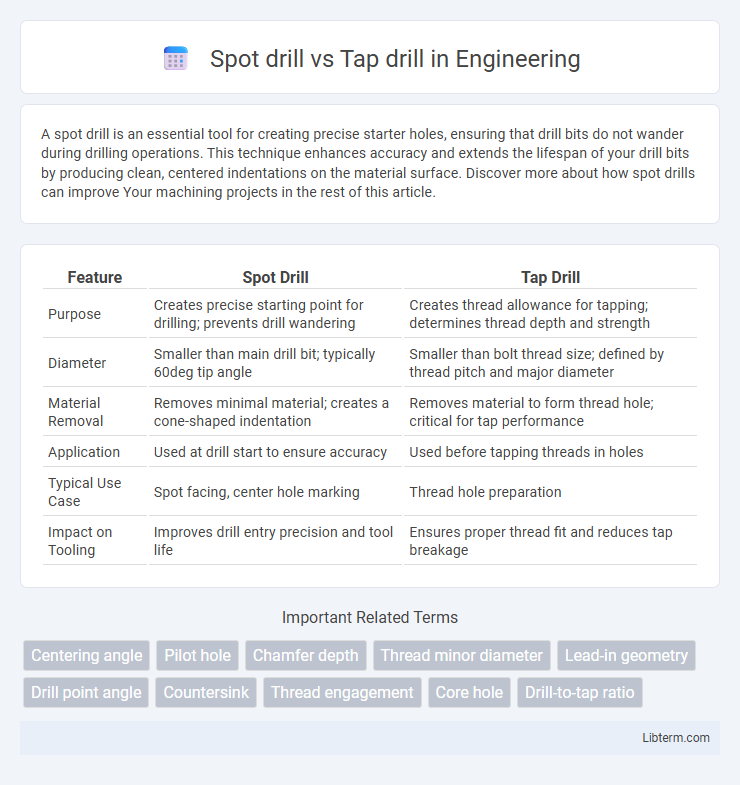

Table of Comparison

| Feature | Spot Drill | Tap Drill |

|---|---|---|

| Purpose | Creates precise starting point for drilling; prevents drill wandering | Creates thread allowance for tapping; determines thread depth and strength |

| Diameter | Smaller than main drill bit; typically 60deg tip angle | Smaller than bolt thread size; defined by thread pitch and major diameter |

| Material Removal | Removes minimal material; creates a cone-shaped indentation | Removes material to form thread hole; critical for tap performance |

| Application | Used at drill start to ensure accuracy | Used before tapping threads in holes |

| Typical Use Case | Spot facing, center hole marking | Thread hole preparation |

| Impact on Tooling | Improves drill entry precision and tool life | Ensures proper thread fit and reduces tap breakage |

Introduction to Spot Drills and Tap Drills

Spot drills create precise starting points for drilling operations by producing shallow guide holes, ensuring drill bits do not wander and enhancing hole accuracy. Tap drills, on the other hand, are sized specifically to leave the correct amount of material for threading, balancing ease of tap penetration with strong thread formation. Understanding the distinct roles of spot drills and tap drills is essential for achieving optimal hole quality and threaded connection performance in machining processes.

Key Differences Between Spot Drill and Tap Drill

Spot drills create a precise pilot hole for accurate drill bit positioning, minimizing walking and ensuring alignment, while tap drills are sized specifically to form the correct hole diameter for threading. Spot drills typically have a shorter length and a robust, rigid design to provide stability during initial drilling, whereas tap drills match the thread pitch and diameter requirements to allow proper thread tapping. The key difference lies in their function: spot drills prepare and position, while tap drills ensure correct hole dimensions for threading operations.

Purpose and Function of Spot Drills

Spot drills are primarily designed to create a small, precise indentation on a workpiece, ensuring accurate location for subsequent drilling operations. They prevent drill wandering by providing a stable starting point, which enhances the accuracy and quality of the hole. In contrast, tap drills focus on creating the correct hole size for threading, emphasizing proper thread engagement and strength rather than initial hole positioning.

Purpose and Function of Tap Drills

Tap drills are specifically designed to create pilot holes that match the desired thread size and pitch for tapping operations, ensuring accurate thread formation and proper thread engagement. Their purpose is to remove enough material to allow a tap to cut threads without excessive force or risk of tool breakage, maintaining the integrity of the threaded hole. Unlike spot drills, which create shallow guides for center drilling, tap drills focus on providing the optimal hole size for threading processes in materials like steel, aluminum, or plastic.

Material Compatibility: Spot Drill vs Tap Drill

Spot drills are designed to create precise starting points for drilling, ensuring better accuracy on materials like stainless steel, aluminum, and titanium by minimizing drill wander. Tap drills are selected based on thread size and pitch, requiring careful material consideration to avoid issues such as thread stripping in softer metals like brass or plastic. Understanding material compatibility helps in choosing the correct drill type, with spot drills enhancing hole positioning and tap drills ensuring proper thread engagement.

Choosing the Right Tool: Spot Drill or Tap Drill

Choosing the right tool between a spot drill and a tap drill depends on the machining objective: a spot drill creates a precise starting point to prevent drill bit wandering, ensuring accurate hole placement, while a tap drill creates an undersized hole suitable for threading operations. The spot drill typically has a short, stiff body and a pilot tip designed to produce a centered depression, which is essential for guiding larger drill bits or taps. Selecting the appropriate drill size and type directly influences thread quality and hole accuracy, making the choice critical for efficient manufacturing and assembly processes.

Common Errors in Using Spot Drills and Tap Drills

Common errors in using spot drills include applying excessive feed rates that cause poor hole quality and premature tool wear, or neglecting to center the drill accurately, leading to misaligned holes. Tap drill mistakes often involve selecting incorrect drill sizes, resulting in improper thread engagement or weakened material strength, and failing to account for material-specific tap drill charts. Both tools require precise speed and lubrication settings to avoid tool breakage and ensure optimal hole and thread integrity.

Best Practices for Drilling and Tapping

Spot drills ensure precise hole positioning and prevent drill bit wandering by creating a small, accurate pilot hole before using a tap drill. Selecting the correct tap drill size, typically 75% to 90% of the thread minor diameter, is essential for creating proper threads without excessive force or material displacement. Using a spot drill followed by a correctly sized tap drill enhances hole accuracy, reduces tool wear, and ensures strong, clean threads in machining processes.

Factors Influencing Drill Selection

Factors influencing drill selection between spot drills and tap drills include the material type, hole size, and desired hole quality. Spot drills create a precise starting point to prevent drill wandering, making them essential for harder materials or when high accuracy is needed. Tap drills require a slightly smaller diameter than the final thread size to ensure proper thread engagement and strength.

Conclusion: Optimizing Machining with Spot and Tap Drills

Spot drills provide precise hole location and prevent drill wandering, essential for accurate hole starts, while tap drills determine the correct hole size for threading to ensure proper thread engagement and strength. Using spot drills before drilling and selecting the appropriate tap drill size optimizes machining efficiency, reduces tool wear, and improves hole quality. Combining these drills enhances overall machining precision and durability in threading applications.

Spot drill Infographic

libterm.com

libterm.com