Magnetic bearings use magnetic fields to support and stabilize rotating shafts without physical contact, reducing friction and wear while allowing high-speed operation and precision control. These bearings are essential in applications like turbines, compressors, and flywheels because they enhance performance and extend equipment lifespan. Discover how magnetic bearings can revolutionize your machinery by reading the full article.

Table of Comparison

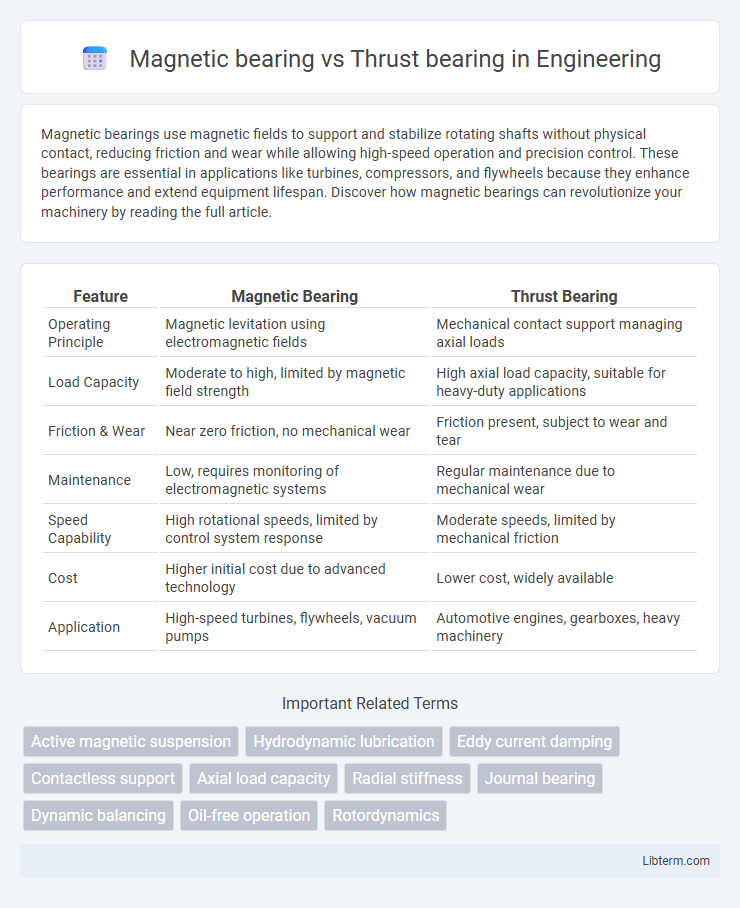

| Feature | Magnetic Bearing | Thrust Bearing |

|---|---|---|

| Operating Principle | Magnetic levitation using electromagnetic fields | Mechanical contact support managing axial loads |

| Load Capacity | Moderate to high, limited by magnetic field strength | High axial load capacity, suitable for heavy-duty applications |

| Friction & Wear | Near zero friction, no mechanical wear | Friction present, subject to wear and tear |

| Maintenance | Low, requires monitoring of electromagnetic systems | Regular maintenance due to mechanical wear |

| Speed Capability | High rotational speeds, limited by control system response | Moderate speeds, limited by mechanical friction |

| Cost | Higher initial cost due to advanced technology | Lower cost, widely available |

| Application | High-speed turbines, flywheels, vacuum pumps | Automotive engines, gearboxes, heavy machinery |

Introduction to Magnetic and Thrust Bearings

Magnetic bearings use electromagnetic forces to support loads without physical contact, reducing friction and wear in high-speed rotating machinery. Thrust bearings, typically composed of rolling elements or fluid films, are designed to handle axial loads and maintain alignment under heavy pressure. Both types play crucial roles in industrial applications, with magnetic bearings offering advantages in precision and maintenance while thrust bearings provide reliable axial load support.

Principles of Operation: Magnetic Bearings

Magnetic bearings operate on the principle of electromagnetic levitation, using magnetic fields to support and stabilize rotating shafts without physical contact, thus reducing friction and wear. These bearings utilize sensors to detect the rotor position and electromagnets to adjust magnetic forces dynamically, maintaining precise shaft alignment. Unlike thrust bearings that rely on mechanical components to handle axial loads, magnetic bearings manage both radial and axial loads through controlled magnetic fields, enhancing performance in high-speed and high-precision applications.

Principles of Operation: Thrust Bearings

Thrust bearings operate by supporting axial loads using rolling elements such as balls or rollers that run between two rings, minimizing friction and wear. The design ensures efficient transfer of force along the shaft axis, enabling high load capacity and durability in rotary machinery. These bearings rely on mechanical contact, contrasting with magnetic bearings that use electromagnetic fields to levitate and support the load without physical contact.

Key Differences Between Magnetic and Thrust Bearings

Magnetic bearings use electromagnetic forces to levitate and support rotating shafts without physical contact, resulting in minimal friction and wear, while thrust bearings rely on physical contact and rolling elements to absorb axial loads. Magnetic bearings provide superior precision, reduced maintenance, and higher rotational speeds compared to thrust bearings, which are typically simpler and more cost-effective for handling axial forces in conventional machinery. The key differences lie in their operational principles, load capacity, friction levels, and maintenance requirements, with magnetic bearings excelling in applications demanding high performance and reliability.

Applications of Magnetic Bearings

Magnetic bearings are predominantly used in high-speed and precision applications such as turbo machinery, vacuum pumps, and flywheel energy storage systems where frictionless operation and minimal wear are critical. These bearings enable operation in harsh environments like clean rooms and vacuum chambers by eliminating lubrication needs, unlike thrust bearings that rely on mechanical contact and lubrication for axial load support. Magnetic bearings also facilitate active vibration control and real-time monitoring, enhancing the reliability and lifespan of rotating equipment in industries like aerospace, power generation, and semiconductor manufacturing.

Applications of Thrust Bearings

Thrust bearings are essential in applications requiring support for axial loads, such as automotive transmissions, marine propellers, and aerospace turbines, where they help maintain shaft position and reduce friction. These bearings are also crucial in heavy machinery, including cranes and gearboxes, by providing stability and durability under high axial forces. Magnetic bearings, while used in high-speed or contamination-sensitive environments, typically complement rather than replace thrust bearings in many industrial applications.

Advantages of Magnetic Bearings

Magnetic bearings offer frictionless operation, enabling higher rotational speeds and reduced wear compared to traditional thrust bearings. Their contactless design minimizes maintenance needs and enhances system longevity by eliminating lubricant dependency. Advanced control systems in magnetic bearings provide precise shaft positioning, improving overall performance and energy efficiency.

Advantages of Thrust Bearings

Thrust bearings provide high load capacity for axial forces in rotating machinery, ensuring stability and precise shaft positioning under heavy loads. They offer reliable performance with minimal maintenance due to their simple mechanical design compared to magnetic bearings. Their robustness and cost-effectiveness make thrust bearings ideal for applications requiring consistent axial load support.

Limitations and Challenges of Each Bearing Type

Magnetic bearings face limitations such as high initial costs, sensitivity to electromagnetic interference, and complex control systems that require continuous power for operation. Thrust bearings, while simpler and cost-effective, encounter challenges including wear and tear under heavy loads, lubrication dependency, and limited performance at extreme speeds or temperatures. Both bearing types demand specific maintenance strategies tailored to their distinct operational vulnerabilities and environmental conditions.

How to Choose Between Magnetic and Thrust Bearings

Choosing between magnetic and thrust bearings depends primarily on load capacity, speed requirements, and maintenance preferences. Magnetic bearings excel in high-speed applications with minimal friction and require no lubrication, making them ideal for precision machinery and aerospace uses. Thrust bearings are better suited for heavy axial loads at lower speeds, offering robustness and cost-effectiveness in industrial and automotive applications.

Magnetic bearing Infographic

libterm.com

libterm.com