Suspension systems play a crucial role in vehicle handling, comfort, and safety by absorbing shocks from road irregularities and maintaining tire contact. Properly maintained suspension improves ride quality, reduces wear on other components, and enhances overall driving performance. Discover how optimizing your suspension can transform your driving experience by reading the rest of this article.

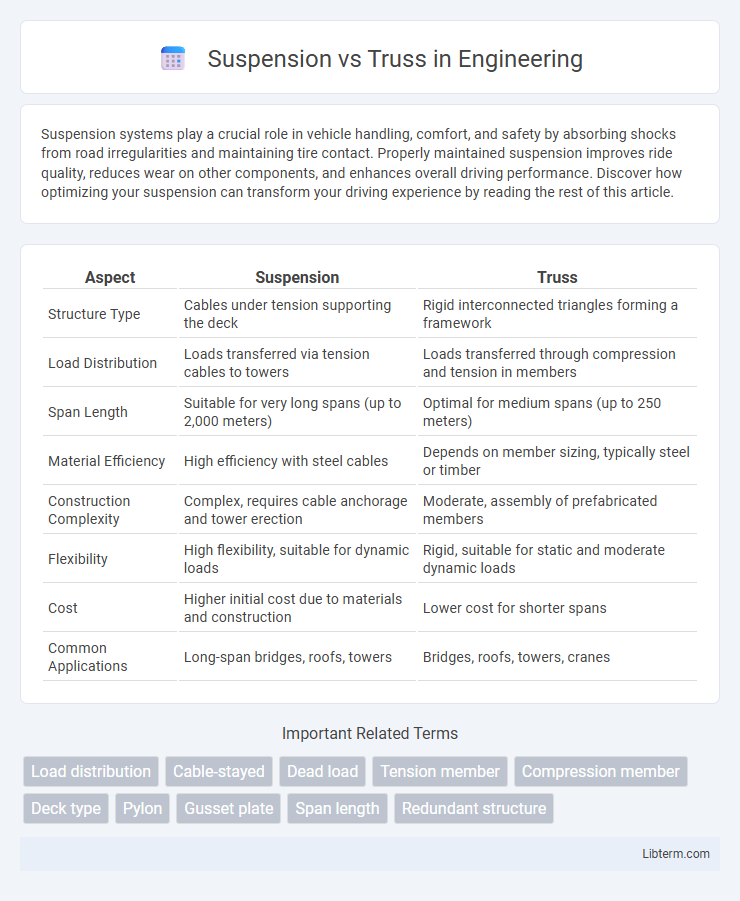

Table of Comparison

| Aspect | Suspension | Truss |

|---|---|---|

| Structure Type | Cables under tension supporting the deck | Rigid interconnected triangles forming a framework |

| Load Distribution | Loads transferred via tension cables to towers | Loads transferred through compression and tension in members |

| Span Length | Suitable for very long spans (up to 2,000 meters) | Optimal for medium spans (up to 250 meters) |

| Material Efficiency | High efficiency with steel cables | Depends on member sizing, typically steel or timber |

| Construction Complexity | Complex, requires cable anchorage and tower erection | Moderate, assembly of prefabricated members |

| Flexibility | High flexibility, suitable for dynamic loads | Rigid, suitable for static and moderate dynamic loads |

| Cost | Higher initial cost due to materials and construction | Lower cost for shorter spans |

| Common Applications | Long-span bridges, roofs, towers | Bridges, roofs, towers, cranes |

Introduction to Suspension and Truss Bridges

Suspension bridges utilize cables suspended between towers to support the bridge deck, allowing for long spans and flexibility, making them ideal for crossing wide bodies of water. Truss bridges consist of interconnected triangular units forming a rigid framework, distributing loads efficiently through compression and tension in the truss elements. Both structures highlight distinct engineering principles, with suspension bridges excelling in span length and truss bridges offering robust load-bearing capacity.

Key Design Principles: Suspension vs Truss

Suspension bridges rely on cables suspended between towers to hold the bridge deck, distributing loads primarily through tension, making them ideal for long spans over water or deep valleys. Truss bridges use a framework of connected triangles that transfer loads through compression and tension within the truss structure, providing high strength and rigidity suitable for shorter spans and heavy loads. Key design principles highlight suspension bridges' efficiency in spanning great distances with minimal material, while truss bridges emphasize material efficiency and load distribution through geometric stability.

Structural Components Comparison

Suspension bridges utilize main cables anchored at both ends, with vertical suspenders supporting the deck, allowing for longer spans and flexibility under loads. Truss bridges consist of interconnected triangular units made from straight steel or wooden elements, distributing forces through compression and tension within the truss framework. The primary structural difference lies in suspension bridges relying on tensile forces in cables, while truss bridges transfer loads through axial forces in rigid members.

Load Distribution and Weight Handling

Suspension bridges distribute loads primarily through cables in tension, transferring weight to towers and anchorages, allowing for longer spans and efficient handling of dynamic loads like wind and traffic. Truss bridges use a rigid framework of interconnected triangles to distribute loads evenly, converting bending forces into tension and compression within the truss members, providing high strength-to-weight ratios ideal for shorter to medium spans. The choice between suspension and truss design depends on specific load distribution needs and span length requirements, with suspension bridges excelling in flexibility and trusses in structural rigidity.

Materials Used in Suspension and Truss Bridges

Suspension bridges primarily use high-strength steel cables, anchorages, and towers made from steel or reinforced concrete to support large spans and provide flexibility. Truss bridges utilize a combination of steel or iron for the triangular framework, which efficiently distributes loads through interconnected elements, often supported by concrete or steel piers. The choice of materials in suspension bridges emphasizes tensile strength and elasticity, while truss bridges rely on the compressive and tensile properties of rigid steel components for stability.

Construction Methods and Challenges

Suspension bridges utilize cables suspended between towers to support the deck, requiring precise tensioning and anchor construction, which can be challenging in unstable soil or high-wind areas. Truss bridges rely on interconnected triangular units that distribute loads efficiently, demanding meticulous fabrication and assembly of components to maintain structural integrity. Both methods face challenges related to material stress, environmental impact, and construction logistics, but suspension bridges typically involve more complex cable installation and longer construction timelines.

Aesthetics and Architectural Appeal

Suspension bridges boast sleek, minimalistic cables that create an airy, elegant silhouette, enhancing urban skylines with their graceful curves. Truss bridges exhibit a geometric complexity through their interwoven steel or wooden frameworks, offering a rugged, industrial aesthetic favored in historical and rustic settings. The choice between suspension's modern sophistication and truss's structural articulation directly influences the visual statement and architectural harmony within the environment.

Common Applications and Use Cases

Suspension bridges are commonly used for long-span crossings such as highways and railways over wide rivers and bays due to their ability to support heavy loads with minimal material use. Truss bridges excel in shorter to medium spans, frequently found in railway overpasses, road bridges, and pedestrian walkways where rigidity and load distribution are critical. Both designs serve distinct roles in infrastructure, with suspension bridges favored for large-scale projects requiring flexibility and aesthetic appeal, while truss bridges offer cost-effective solutions for moderate spans with high strength demands.

Durability, Maintenance, and Lifespan

Suspension bridges generally offer superior durability due to their flexible cables and ability to withstand dynamic loads, but they require regular maintenance to prevent cable corrosion and fatigue. Truss bridges, with their rigid framework of interconnected elements, typically experience lower maintenance needs and a longer lifespan, particularly in environments where corrosion can be effectively controlled. Both types benefit from advances in materials engineering, although truss bridges often have a lifespan exceeding 75 years, while suspension bridges average around 50 to 70 years depending on environmental conditions.

Cost Efficiency and Long-Term Investment

Suspension bridges often demand higher initial costs due to complex cable systems and foundation requirements, yet offer exceptional span lengths and aesthetic appeal, potentially increasing long-term value. Truss bridges provide cost-effective construction with simpler materials and easier maintenance, making them suitable for shorter spans and budget-conscious projects. Evaluating lifecycle costs, including durability and maintenance, positions suspension bridges as a long-term investment in iconic infrastructure, while truss bridges excel in immediate cost efficiency and functional reliability.

Suspension Infographic

libterm.com

libterm.com