Bending moment refers to the internal force induced in a structural element when it experiences bending due to external loads. Understanding bending moments is critical for designing safe beams, bridges, and other structures to prevent failure or excessive deformation. Explore the detailed concepts and calculations in the rest of the article to strengthen your grasp on this fundamental engineering principle.

Table of Comparison

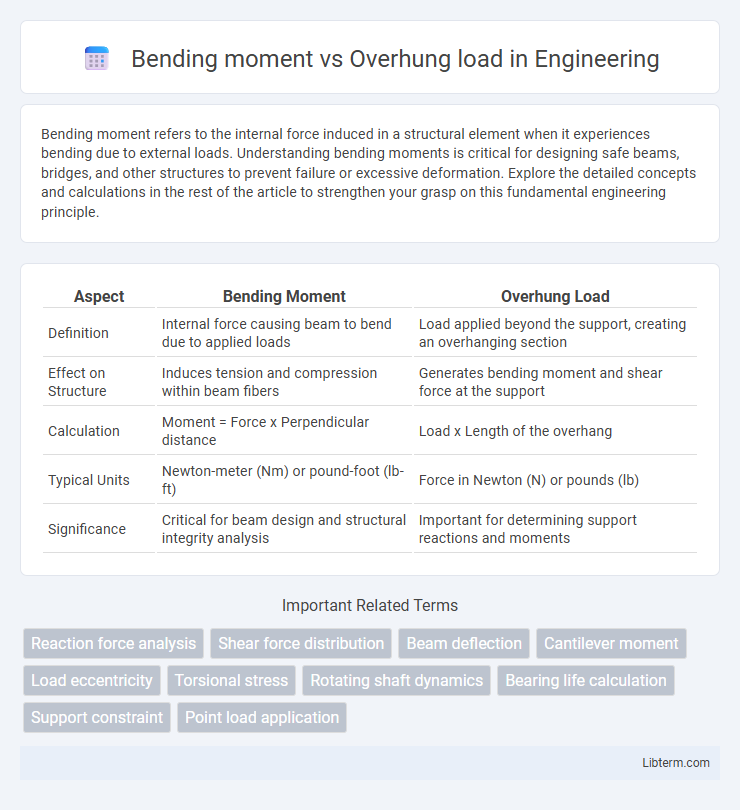

| Aspect | Bending Moment | Overhung Load |

|---|---|---|

| Definition | Internal force causing beam to bend due to applied loads | Load applied beyond the support, creating an overhanging section |

| Effect on Structure | Induces tension and compression within beam fibers | Generates bending moment and shear force at the support |

| Calculation | Moment = Force x Perpendicular distance | Load x Length of the overhang |

| Typical Units | Newton-meter (Nm) or pound-foot (lb-ft) | Force in Newton (N) or pounds (lb) |

| Significance | Critical for beam design and structural integrity analysis | Important for determining support reactions and moments |

Understanding Bending Moment: Definition and Principles

Bending moment is a measure of the internal forces causing a beam or structural element to bend under an applied load, such as an overhung load. It is calculated by multiplying the magnitude of the load by the distance from the support point, which creates a moment that tends to rotate the beam about the support. Understanding bending moment is crucial for designing beams to ensure they can withstand applied forces without excessive deformation or failure.

What Is Overhung Load? Key Concepts Explained

Overhung load refers to a type of load applied beyond the support or fixed point of a beam or structure, creating a lever arm that induces bending moments and shear forces. The bending moment generated by an overhung load is calculated by multiplying the load magnitude by its distance from the support, resulting in increased stress and potential deflection in the cantilevered section. Understanding the relationship between bending moment and overhung load is critical for designing structural elements to ensure stability and prevent failure under applied loads.

Fundamental Differences Between Bending Moment and Overhung Load

Bending moment refers to the internal moment that causes a beam to bend due to applied loads, varying along the length of the beam and dependent on load magnitude, position, and support conditions. Overhung load is a specific external load applied beyond the support of a cantilever or beam, creating an overhanging segment that generates bending moments and shear forces at the support. The fundamental difference lies in bending moment being an internal response within a structure, while overhung load is an external applied force causing that internal response.

How Overhung Load Influences Bending Moment

An overhung load significantly increases the bending moment on a beam by introducing an additional moment arm beyond the support, resulting in higher stress concentrations near the support point. The magnitude of the bending moment is directly proportional to the distance of the overhung load from the fixed support and the magnitude of the applied load itself. Engineers must carefully consider overhung loads during structural design to ensure material strength and stability under increased bending moments.

Calculation Methods: Bending Moment vs. Overhung Load

Calculation methods for bending moment in an overhung load scenario involve applying static equilibrium equations to determine moments at critical points. The bending moment is computed by multiplying the magnitude of the overhung load by the distance from the support or fixed point, accounting for moments caused by reactions and external forces. Precise analysis entails using formulas such as M = P x a, where P is the load and a is the distance from the fixed support, optimizing structural design against bending stresses.

Common Applications in Engineering and Mechanics

Bending moment caused by an overhung load critically influences the design of cantilever beams, crane booms, and overhanging structural elements in bridges and buildings. Engineers calculate bending moments to ensure materials withstand stress and prevent failures in mechanical arms, load-bearing platforms, and support brackets. Common applications include crane lifting operations, cantilever signs, and extended balconies, where precise bending moment analysis guarantees safety and performance under varying load conditions.

Effects on Shaft and Beam Design

Bending moment increases significantly with an overhung load, causing higher stress concentrations at the fixed support or bearing location of shafts and beams. Shaft design must account for these moments by selecting appropriate diameters and materials to prevent failure from fatigue and bending stress. Beam design requires reinforced cross-sections or support alterations to accommodate the increased bending moments and avoid excessive deflection or structural damage.

Practical Examples: Real-World Scenarios

Overhung load scenarios often create significant bending moments in cantilever beams, such as in crane booms and balcony cantilevers, where the load extends beyond the support point causing maximum moment at the fixed end. For instance, in a crane lifting a heavy object, the bending moment is calculated by multiplying the load by the distance from the support, which guides structural reinforcement and material selection. Similarly, overhung loads on bridge projections must consider bending moments to prevent failure, ensuring safety and durability through precise engineering analysis.

Failure Modes: Risks of Excessive Bending Moment and Overhung Load

Excessive bending moment in beams can cause yielding or plastic deformation, leading to permanent structural damage and potential collapse. Overhung loads increase the cantilever effect, significantly raising the bending moment and shear forces at the support, which can trigger localized buckling or fracture. Both failure modes risk compromising structural integrity, especially in cantilevered beams or equipment with extended load points, necessitating careful load and moment calculations to prevent catastrophic failures.

Best Practices for Minimizing Overhung Load and Bending Moment

Minimizing overhung load and bending moment requires strategic support placement and load distribution to reduce stress concentrations on beams. Utilizing shorter cantilever lengths and adding intermediate supports or braces effectively lower bending moments, enhancing structural stability. Selecting materials with higher strength-to-weight ratios and reinforcing critical sections can further mitigate deformation and extend service life.

Bending moment Infographic

libterm.com

libterm.com