Gear pumps deliver consistent fluid flow by using meshing gears to transfer liquids with high precision and efficiency. Their compact design and reliability make them ideal for hydraulic systems, fuel transfer, and lubrication applications. Explore the rest of the article to understand how a gear pump can optimize your fluid handling needs.

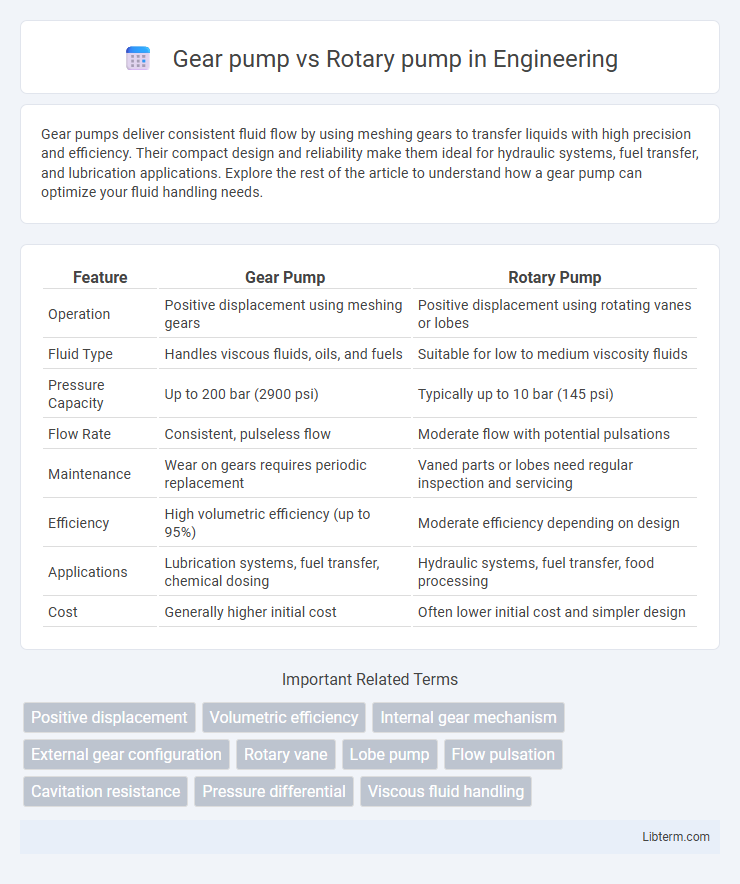

Table of Comparison

| Feature | Gear Pump | Rotary Pump |

|---|---|---|

| Operation | Positive displacement using meshing gears | Positive displacement using rotating vanes or lobes |

| Fluid Type | Handles viscous fluids, oils, and fuels | Suitable for low to medium viscosity fluids |

| Pressure Capacity | Up to 200 bar (2900 psi) | Typically up to 10 bar (145 psi) |

| Flow Rate | Consistent, pulseless flow | Moderate flow with potential pulsations |

| Maintenance | Wear on gears requires periodic replacement | Vaned parts or lobes need regular inspection and servicing |

| Efficiency | High volumetric efficiency (up to 95%) | Moderate efficiency depending on design |

| Applications | Lubrication systems, fuel transfer, chemical dosing | Hydraulic systems, fuel transfer, food processing |

| Cost | Generally higher initial cost | Often lower initial cost and simpler design |

Introduction to Gear Pumps and Rotary Pumps

Gear pumps use meshing gears to pump fluid by displacement, creating consistent and precise flow commonly utilized in hydraulic systems and lubrication applications. Rotary pumps operate by trapping fluid between rotating components, such as gears, vanes, or lobes, enabling efficient handling of viscous fluids and maintaining steady pressure. Both pump types excel in low-pulsation delivery, with gear pumps offering robust performance for high-pressure tasks and rotary pumps providing versatility across a broader range of fluid types.

Basic Working Principles

Gear pumps operate by using meshing gears to create a fixed displacement that moves fluid through the pump with consistent pressure and flow rates. Rotary pumps function through the rotation of internal components such as gears, lobes, or vanes, which trap fluid and transfer it from the inlet to the outlet in a continuous flow. Both pump types rely on the mechanical motion of elements to create suction and discharge, but gear pumps specifically utilize interlocking gears, while rotary pumps encompass a broader range of rotating mechanisms.

Key Design Differences

Gear pumps feature interlocking gears that create precise volumetric displacement, offering high pressure and consistent flow ideal for viscous fluids. Rotary pumps utilize a rotating mechanism such as lobes or vanes, providing smoother flow with less pulsation but generally lower pressure capabilities. Gear pumps have sealed gear chambers with minimal clearance for tight sealing, while rotary pumps emphasize flexible clearances for handling varied fluid viscosities and minimizing wear.

Performance and Efficiency Comparison

Gear pumps deliver consistent flow rates with excellent pressure capabilities, making them ideal for high-viscosity fluids and precise metering applications. Rotary pumps, which include internal and external gear varieties, generally offer higher volumetric efficiency and smoother operation at variable speeds, reducing pulsation and noise. Performance-wise, gear pumps excel in durability and robustness under high-load conditions, while rotary pumps provide superior overall efficiency in low to medium pressure systems due to reduced internal leakage.

Advantages of Gear Pumps

Gear pumps offer precise and consistent flow rates, making them ideal for hydraulic systems requiring reliable pressure control. Their robust design provides excellent durability and the capability to handle high-viscosity fluids without compromising efficiency. These pumps also exhibit low pulsation flow, reducing noise and vibration in industrial applications.

Advantages of Rotary Pumps

Rotary pumps offer superior efficiency and consistent flow rate compared to gear pumps, making them ideal for handling viscous fluids in industrial applications. Their compact design and low pulsation result in smoother operation and reduced noise levels, enhancing equipment longevity. Rotary pumps also provide better self-priming capabilities and versatility across various fluid types, improving overall performance and reliability.

Common Applications

Gear pumps are commonly used in hydraulic systems, lubrication systems, and fuel transfer due to their ability to handle high viscosity fluids with consistent flow rates. Rotary pumps find frequent applications in chemical processing, food and beverage industries, and oil transfer because of their efficiency in handling varying fluid viscosities and delicate materials. Both pump types are essential in industrial, automotive, and manufacturing sectors where precise fluid control and reliability are critical.

Maintenance and Reliability

Gear pumps exhibit high reliability due to their simple design and fewer moving parts, resulting in lower maintenance requirements and longer service intervals compared to rotary pumps. The close tolerances and constant meshing of gear teeth in gear pumps minimize leakage and wear, enhancing operational efficiency and reducing downtime. Rotary pumps, while versatile, often require more frequent maintenance because of seal wear and potential clogging, impacting overall reliability in demanding industrial applications.

Cost Considerations

Gear pumps generally offer lower initial costs compared to rotary pumps due to simpler design and manufacturing processes. Maintenance expenses for gear pumps can be higher because of gear wear, while rotary pumps typically provide longer service life with less frequent repairs, impacting total cost of ownership. Selecting between the two often depends on balancing upfront investment with anticipated maintenance and operational expenses.

Choosing the Right Pump for Your Needs

Selecting the right pump depends on factors like fluid type, pressure requirements, and flow rate. Gear pumps are ideal for handling high-viscosity fluids at constant flow rates with moderate pressure, offering durability in hydraulic and lubrication systems. Rotary pumps excel in applications requiring smooth, pulsation-free flow with low to medium viscosity fluids, making them suitable for chemical processing and fuel transfer.

Gear pump Infographic

libterm.com

libterm.com