Runout tolerance defines the permissible deviation of a rotating component's surface from its ideal circular path, ensuring proper alignment and function in mechanical systems. Maintaining accurate runout tolerance is crucial to prevent premature wear, vibration, and imbalance in machinery. Explore the rest of the article to understand how to measure, control, and optimize runout tolerance for your applications.

Table of Comparison

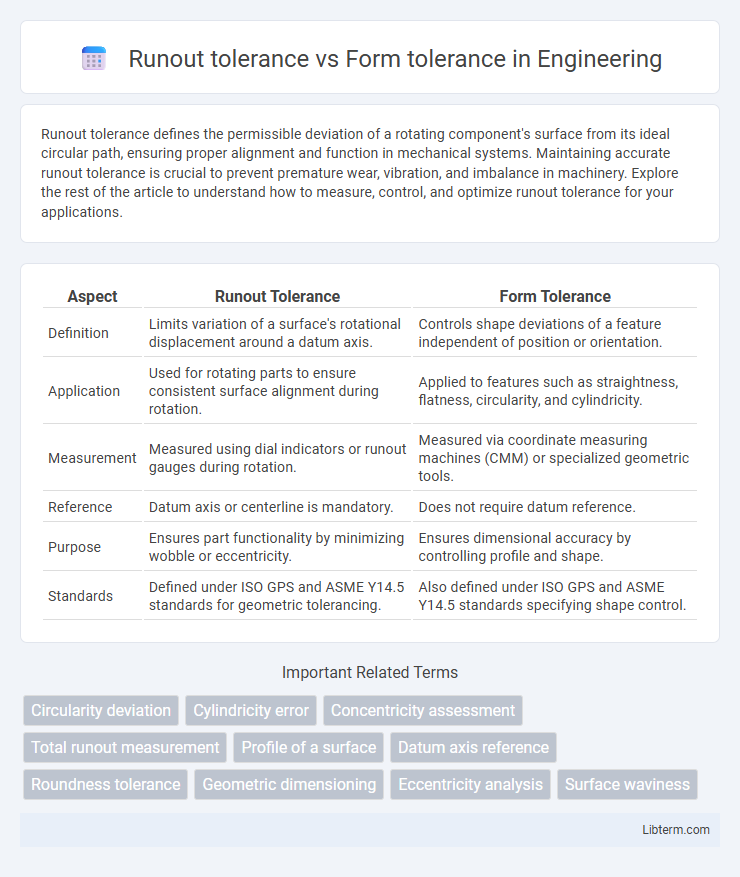

| Aspect | Runout Tolerance | Form Tolerance |

|---|---|---|

| Definition | Limits variation of a surface's rotational displacement around a datum axis. | Controls shape deviations of a feature independent of position or orientation. |

| Application | Used for rotating parts to ensure consistent surface alignment during rotation. | Applied to features such as straightness, flatness, circularity, and cylindricity. |

| Measurement | Measured using dial indicators or runout gauges during rotation. | Measured via coordinate measuring machines (CMM) or specialized geometric tools. |

| Reference | Datum axis or centerline is mandatory. | Does not require datum reference. |

| Purpose | Ensures part functionality by minimizing wobble or eccentricity. | Ensures dimensional accuracy by controlling profile and shape. |

| Standards | Defined under ISO GPS and ASME Y14.5 standards for geometric tolerancing. | Also defined under ISO GPS and ASME Y14.5 standards specifying shape control. |

Understanding Runout Tolerance

Runout tolerance defines the allowable deviation of a rotating surface from its true axis of rotation, critical in minimizing vibration and ensuring smooth mechanical operation. It is measured using dial indicators and is essential for components like shafts and gears where precise concentricity impacts performance. Understanding runout tolerance allows engineers to control dynamic behavior and prevent premature wear in rotating machinery.

Defining Form Tolerance

Form tolerance specifies the allowable deviation of a feature's shape from its ideal geometric form, ensuring the surface or profile adheres closely to design specifications. It controls characteristics such as flatness, straightness, roundness, and cylindricity, providing a strict boundary for shape accuracy. Unlike runout tolerance, which measures the variation of a surface relative to a datum during rotation, form tolerance applies universally without referencing a datum or rotational movement.

Key Differences: Runout vs Form Tolerance

Runout tolerance controls the variation of a surface as it rotates around a datum axis, ensuring the part's concentricity and rotational accuracy, while form tolerance controls the shape of a feature such as flatness, straightness, or roundness without relation to any datum. Runout is a composite tolerance combining form, orientation, and sometimes location errors in a single specification, primarily applied to cylindrical parts or rotating elements. Form tolerance strictly limits geometric imperfections within the feature itself, focusing on intrinsic shape control rather than positional deviation.

When to Use Runout Tolerance

Runout tolerance is essential for controlling the variation of circular elements during rotation, especially in components such as shafts and gears where precision in concentricity and surface uniformity affects performance. Use runout tolerance when assessing dynamic parts that undergo rotational motion to ensure smooth operation and minimize vibration or wear. Form tolerance, by contrast, applies primarily to static surface geometry and is suited for controlling flatness, straightness, and roundness without accounting for rotational alignment.

Ideal Applications for Form Tolerance

Form tolerance applies to individual features such as flatness, straightness, and roundness, ensuring precise geometric shapes without referencing other parts. Ideal applications for form tolerance include components like shafts, bearings, and sealing surfaces where strict control over shape accuracy directly impacts performance and assembly. Compared to runout tolerance, which addresses variation in rotational elements relative to a datum, form tolerance is crucial for maintaining intrinsic geometry in stationary or single-feature parts.

Measurement Techniques for Runout

Runout tolerance quantifies the radial deviation of a rotating surface relative to its axis, measured using dial indicators or coordinate measuring machines (CMM) to capture variations during rotation. Form tolerance defines the geometric shape accuracy of a feature, assessed through profile projectors or surface finish testers focusing on deviations from ideal forms such as flatness or cylindricity. Measurement techniques for runout emphasize dynamic analysis by rotating the part and recording displacement at multiple points, ensuring precision in balancing and alignment tasks.

Methods for Inspecting Form Tolerance

Form tolerance inspection methods include coordinate measuring machines (CMM), optical comparators, and surface profilometers that precisely evaluate geometric features such as flatness, roundness, and straightness. These techniques use probe-based measurements or laser scanning to generate detailed surface maps, enabling quantification of deviations within specified form tolerance limits. Advanced software algorithms interpret the collected data, comparing actual geometry against CAD models to ensure compliance with design requirements.

Impact on Manufacturing Precision

Runout tolerance directly affects rotational accuracy by controlling variations in the circularity and concentricity of rotating parts, critical for high-speed machinery and precision assemblies. Form tolerance governs the shape and consistency of surfaces, ensuring that manufactured components meet strict dimensional requirements to fit and function properly. Precise control of both tolerances is essential for minimizing errors during manufacturing, reducing wear, and improving the overall performance and lifespan of mechanical systems.

Common Mistakes in Applying Tolerances

Common mistakes in applying runout tolerance versus form tolerance include confusing their respective control aspects, where runout tolerance governs the deviation of a surface during rotation and form tolerance controls the inherent shape irregularities. Engineers often misapply runout tolerances to non-rotating parts or overlook the importance of datum selection, resulting in inaccurate measurements and functional failures. Neglecting to distinguish between total runout and circular runout limits can lead to improper inspection methods and compromised assembly precision.

Best Practices for Specifying Tolerances

Runout tolerance controls the deviation of a rotating feature from its ideal axis, ensuring precise alignment in assemblies with rotating parts, while form tolerance governs the shape accuracy of a single feature such as straightness, flatness, or roundness. Best practices for specifying these tolerances involve clearly distinguishing functional requirements by applying runout tolerance for dynamic parts and form tolerance for static features to prevent over-tightening or under-specification. Using geometric dimensioning and tolerancing (GD&T) standards, engineers should define the datum references precisely to enhance manufacturing consistency and inspection reliability for both tolerances.

Runout tolerance Infographic

libterm.com

libterm.com