Maximum temperature refers to the highest temperature recorded in a specific location over a given period, often crucial for understanding local climate trends and weather patterns. This data helps predict heatwaves, plan agricultural activities, and manage energy consumption effectively. Explore the rest of this article to discover how maximum temperature impacts your daily life and environment.

Table of Comparison

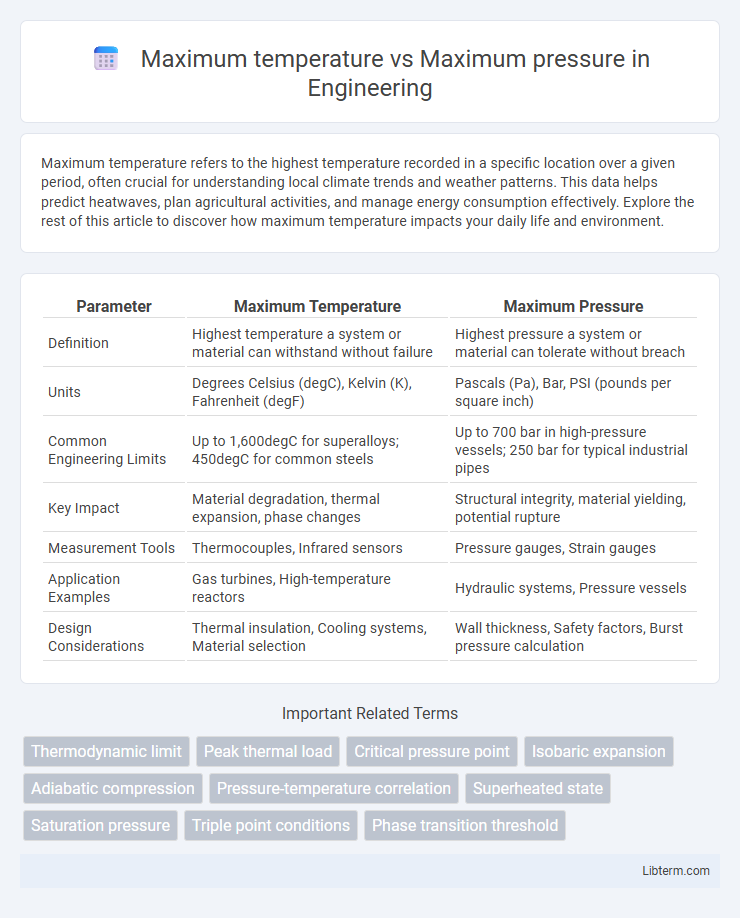

| Parameter | Maximum Temperature | Maximum Pressure |

|---|---|---|

| Definition | Highest temperature a system or material can withstand without failure | Highest pressure a system or material can tolerate without breach |

| Units | Degrees Celsius (degC), Kelvin (K), Fahrenheit (degF) | Pascals (Pa), Bar, PSI (pounds per square inch) |

| Common Engineering Limits | Up to 1,600degC for superalloys; 450degC for common steels | Up to 700 bar in high-pressure vessels; 250 bar for typical industrial pipes |

| Key Impact | Material degradation, thermal expansion, phase changes | Structural integrity, material yielding, potential rupture |

| Measurement Tools | Thermocouples, Infrared sensors | Pressure gauges, Strain gauges |

| Application Examples | Gas turbines, High-temperature reactors | Hydraulic systems, Pressure vessels |

| Design Considerations | Thermal insulation, Cooling systems, Material selection | Wall thickness, Safety factors, Burst pressure calculation |

Understanding Maximum Temperature vs Maximum Pressure

Maximum temperature and maximum pressure are critical parameters in thermodynamics that influence system behavior and material performance. Maximum temperature refers to the highest heat level a system can withstand, affecting reaction rates and material stability, while maximum pressure denotes the peak force exerted per unit area, impacting structural integrity and phase changes. Understanding the relationship between maximum temperature and maximum pressure is essential for designing safe and efficient engineering systems, such as combustion engines and pressure vessels.

Fundamental Definitions and Differences

Maximum temperature refers to the highest thermal reading reached within a system, measured in units such as degrees Celsius or Fahrenheit, indicating the system's thermal energy at its peak state. Maximum pressure denotes the greatest force exerted per unit area within a confined space, typically measured in pascals or psi, representing the system's mechanical stress limit. The fundamental difference lies in temperature measuring thermal energy intensity, while pressure measures force distribution, making both critical but distinct parameters in thermodynamic and mechanical analyses.

Physical Principles Behind Temperature and Pressure

Maximum temperature correlates with the kinetic energy of particles, reflecting the average speed of molecular motion, while maximum pressure arises from particle collisions against container walls. According to the ideal gas law, pressure is directly proportional to temperature when volume and particle number are constant, demonstrating their interdependence. Understanding these physical principles enables accurate predictions in thermodynamics and fluid mechanics applications.

Measurement Methods for Maximum Temperature

Maximum temperature measurement methods primarily include thermocouples, resistance temperature detectors (RTDs), and infrared thermometers, each offering precise readings under different conditions. Thermocouples provide quick response times and can measure extreme temperatures up to 2500degC, while RTDs offer high accuracy and stability for temperatures typically below 600degC. Infrared thermometers enable non-contact temperature measurement, ideal for moving or hazardous environments, enhancing safety and efficiency in monitoring maximum temperature during pressure-related processes.

Techniques for Recording Maximum Pressure

Techniques for recording maximum pressure include the use of high-precision pressure transducers, piezoelectric sensors, and strain gauge sensors, which provide accurate real-time data under varying temperature conditions. Maximum temperature significantly impacts sensor calibration and material properties, necessitating compensation algorithms to ensure reliable pressure readings. Digital data acquisition systems paired with advanced signal processing enhance the detection and recording of peak pressure values in dynamic environments.

Industrial Applications: Temperature vs. Pressure

In industrial applications, maximum temperature and maximum pressure are critical parameters that directly influence equipment design, safety, and operational efficiency. High-temperature processes, such as in chemical reactors or turbines, require materials resistant to thermal degradation, while high-pressure systems, like hydraulic presses or pressure vessels, demand robust mechanical strength to prevent failure. Balancing temperature and pressure limits ensures optimal performance, minimizes risk of leaks or explosions, and extends the lifespan of industrial components.

Material Limitations and Safety Concerns

Maximum temperature and maximum pressure are critical factors influencing material limitations, as elevated temperatures can degrade structural strength and accelerate corrosion, while high pressures increase stress and the likelihood of mechanical failure. Materials must be selected based on their creep resistance, tensile strength, and thermal stability to ensure safe operation within specified temperature and pressure ranges. Ignoring these parameters poses serious safety concerns, including rupture, leakages, and catastrophic equipment failure, necessitating rigorous testing and adherence to design codes.

Impact on Performance and Efficiency

Maximum temperature significantly influences engine performance by enhancing combustion efficiency, leading to increased power output and fuel economy. However, elevated maximum pressure can improve mechanical work extraction but also raises the risk of engine knocking and structural stress, potentially reducing reliability. Balancing maximum temperature and pressure is crucial for optimizing thermal efficiency while maintaining engine durability and operational safety.

Case Studies Comparing Temperature and Pressure Extremes

Case studies comparing maximum temperature and maximum pressure extremes reveal distinct patterns in industrial and environmental applications. For instance, jet engine testing demonstrates that while maximum temperature primarily governs material selection due to thermal stress, maximum pressure critically influences structural integrity and safety margins. Data from deep-sea drilling operations show maximum pressure outweighs temperature in failure risks, highlighting the necessity to balance both parameters for optimal design and operational efficiency.

Future Trends in Managing Maximum Temperature and Pressure

Future trends in managing maximum temperature and pressure emphasize the integration of advanced materials with enhanced thermal stability and pressure resistance, enabling safer and more efficient industrial processes. Innovations in real-time monitoring technologies using IoT sensors and AI algorithms facilitate precise control and early detection of critical temperature and pressure thresholds. Sustainable engineering practices drive the development of energy-efficient systems that optimize maximum temperature and pressure management while reducing environmental impact.

Maximum temperature Infographic

libterm.com

libterm.com