Electromechanical relays use an electromagnetic coil to mechanically switch electrical contacts, enabling control of high-power circuits with low-power signals. Their reliable switching action is essential in automation, industrial equipment, and protection systems. Discover how understanding your electromechanical relay can optimize your electrical applications in the rest of this article.

Table of Comparison

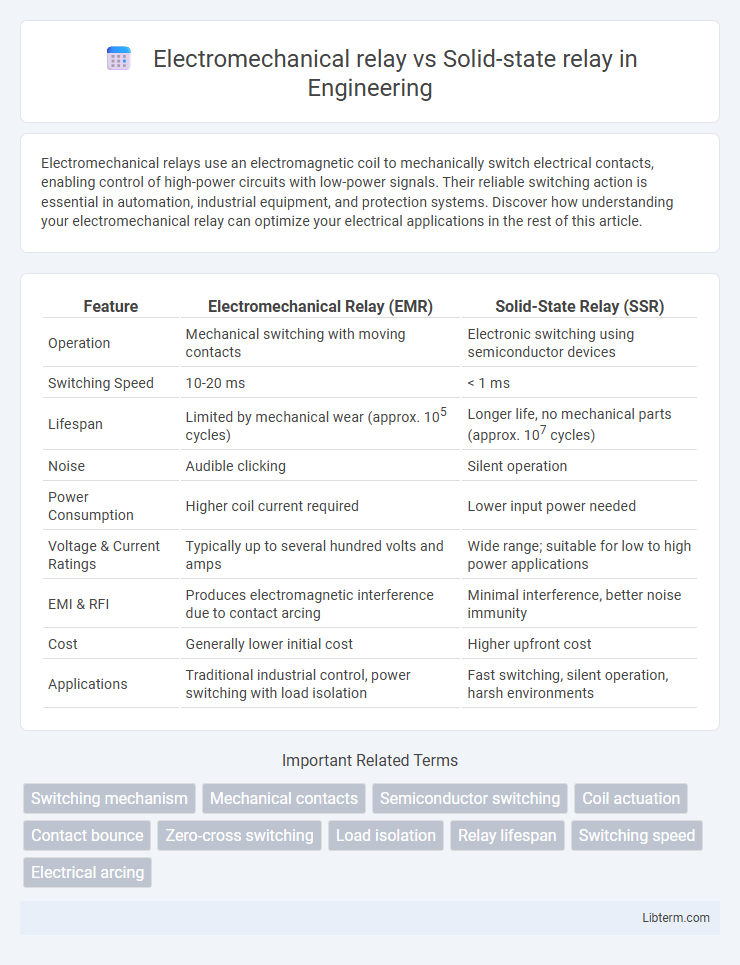

| Feature | Electromechanical Relay (EMR) | Solid-State Relay (SSR) |

|---|---|---|

| Operation | Mechanical switching with moving contacts | Electronic switching using semiconductor devices |

| Switching Speed | 10-20 ms | < 1 ms |

| Lifespan | Limited by mechanical wear (approx. 105 cycles) | Longer life, no mechanical parts (approx. 107 cycles) |

| Noise | Audible clicking | Silent operation |

| Power Consumption | Higher coil current required | Lower input power needed |

| Voltage & Current Ratings | Typically up to several hundred volts and amps | Wide range; suitable for low to high power applications |

| EMI & RFI | Produces electromagnetic interference due to contact arcing | Minimal interference, better noise immunity |

| Cost | Generally lower initial cost | Higher upfront cost |

| Applications | Traditional industrial control, power switching with load isolation | Fast switching, silent operation, harsh environments |

Introduction to Electromechanical and Solid-State Relays

Electromechanical relays use a physical moving contact to open or close circuits, making them suitable for applications requiring electrical isolation and high current capacity. Solid-state relays rely on semiconductor components, such as thyristors or triacs, providing faster switching times, greater durability, and noise-free operation. Choosing between electromechanical and solid-state relays depends on factors like switching speed, electrical noise sensitivity, and load type.

Core Operating Principles

Electromechanical relays operate using an electromagnetic coil to mechanically move contacts, enabling or interrupting current flow with physical switching. Solid-state relays rely on semiconductor components such as thyristors, triacs, or transistors to perform switching without moving parts, resulting in faster response times and increased durability. The absence of mechanical contacts in solid-state relays eliminates contact wear and arcing, making them ideal for high-frequency switching applications.

Key Components and Construction

Electromechanical relays consist of an electromagnetic coil, a movable armature, and physical contacts that open or close circuits through mechanical movement. Solid-state relays feature semiconductor devices such as thyristors, triacs, or transistors to switch circuits without moving parts, enhancing durability and switching speed. The absence of mechanical components in solid-state relays reduces wear and noise, while the physical contacts in electromechanical relays provide galvanic isolation between control and output circuits.

Switching Mechanism Comparison

Electromechanical relays operate using physical moving contacts that open or close circuits through electromagnetic force, which causes mechanical wear and slower response times. Solid-state relays rely on semiconductor components such as thyristors, TRIACs, or transistors to switch circuits electronically without moving parts, resulting in faster switching and enhanced durability. The absence of mechanical components in solid-state relays reduces contact bounce and extends operational lifespan compared to the electromechanical counterpart.

Performance and Response Time

Electromechanical relays feature mechanical contacts resulting in slower response times, typically around 5 to 15 milliseconds, and exhibit wear over time due to physical contact degradation. Solid-state relays utilize semiconductor components, enabling faster switching speeds often under 1 millisecond, enhancing performance in high-frequency applications. The absence of moving parts in solid-state relays also contributes to greater durability and reliability under rapid or frequent switching conditions.

Longevity and Reliability

Electromechanical relays feature mechanical moving parts that are prone to wear and typically have a lifespan ranging from 100,000 to 10 million operations, impacting their long-term reliability. Solid-state relays (SSRs) utilize semiconductor components, offering significantly higher longevity with operational lifespans exceeding 100 million cycles due to the absence of mechanical wear. SSRs also provide enhanced reliability in high-vibration or high-frequency switching environments, making them ideal for applications requiring extended maintenance-free performance.

Applications and Use Cases

Electromechanical relays are ideal for applications requiring high current switching and galvanic isolation, such as industrial motor controls, automotive systems, and general-purpose switching in household appliances. Solid-state relays excel in scenarios demanding fast switching, silent operation, and high reliability, making them suitable for HVAC systems, semiconductor manufacturing, and precision temperature control in medical devices. Their distinct characteristics influence the selection based on load type, switching speed, and environmental conditions in diverse use cases.

Advantages of Electromechanical Relays

Electromechanical relays offer distinct advantages such as mechanical isolation between control and load circuits, enabling safe operation in high voltage environments. Their ability to handle high surge currents and provide clear, audible switching feedback makes them reliable for heavy-duty industrial applications. Furthermore, electromechanical relays exhibit lower on-state resistance, resulting in reduced power loss during operation compared to solid-state relays.

Advantages of Solid-State Relays

Solid-state relays (SSRs) offer significant advantages over electromechanical relays, including faster switching speeds and longer operational lifespan due to the absence of moving parts, resulting in reduced wear and maintenance requirements. SSRs provide silent operation, making them highly suitable for noise-sensitive environments, and they exhibit greater resistance to shock and vibration, enhancing reliability in harsh conditions. Their low power consumption and improved electromagnetic interference (EMI) immunity contribute to energy efficiency and stable performance in complex electronic systems.

Selection Criteria and Recommendations

Electromechanical relays offer robust switching capabilities and are ideal for applications requiring high voltage and current handling with audible feedback, while solid-state relays provide faster switching, longer life, and silent operation suitable for sensitive electronic environments. Selection criteria center on load type, switching speed, electrical isolation, and environmental conditions; electromechanical relays excel in heavy-duty applications, whereas solid-state relays are preferred for frequent, noise-sensitive, or low-power loads. Recommendations emphasize choosing solid-state relays for fast, silent, and maintenance-free performance, and electromechanical relays when cost-effectiveness, high surge current tolerance, and mechanical feedback are critical.

Electromechanical relay Infographic

libterm.com

libterm.com